Business model / Strategy

The Dürr Group is one of the world’s leading mechanical and plant engineering firms. Our technology boasts automation and a high degree of digitalization in order to help customers make their production more efficient while at the same time conserving natural resources.

Business Model

Our core competence is the engineering of efficient production technology. We offer our customers a full range of options from individual machines to turnkey manufacturing systems. In this context, our offering in digital networking and control of production systems is becoming increasingly important.

Our technologies and services help our customers achieve efficient and sustainable production by focusing on the following primary factors:

- Digitalization, automation and technological innovation

- development of material-efficient, energy-saving, and low-emission products

- planning, engineering, and order processing know-how

- a comprehensive range of services for the entire life cycle of our products

- global presence, proximity to customers in all market regions

We operate in niche markets, where we are either the market leader or among the largest suppliers, with market shares ranging from 15% to 55%. In 2023, 61% of Group sales came from mechanical engineering and 39% from plant engineering. In mechanical engineering, we aim for EBIT margins of 10% or more; in plant engineering, the target margin is over at least 6%. In terms of return on capital employed (ROCE), we target a figure of 25% or more. In principle, our business model allows us to achieve high operating and free cash flows. From 2025, free cash flow should permanently amount to at least 80% of earnings after taxes.

Strategy

Our corporate strategy is oriented to both profitability and growth. It aims to act on opportunities in established core business as well as in new or high-growth business areas. In established business, the focus is on expanding market leadership and profitability. We call the new business areas “growth business”. They are characterized by high growth potential and access to new markets and customers.

- Established Business

Established business mainly entails paint shops, painting robots, and final assembly technology, for the automotive industry, environmental technology, balancing, tooling and filling systems as well as HOMAG machinery for furniture production. We hold leading global market positions in these areas and expect them to generate moderate to medium sales growth. The main priority in established business is to enhance profitability. - Growth Business

Growth business consists of three business areas (Construction Elements Solutions, Production Automation Systems, Battery Production) with potential for strong, above-average sales growth. Aggregated sales from growth business reached roughly €500 million in 2023. By expanding our activities, we are aiming to increase this to a total of €1.6 to €1.8 billion by 2030. In this way, the three growth business areas are to make the greatest contribution to the growth in Group sales to more than €6 billion.

Target Key Figures

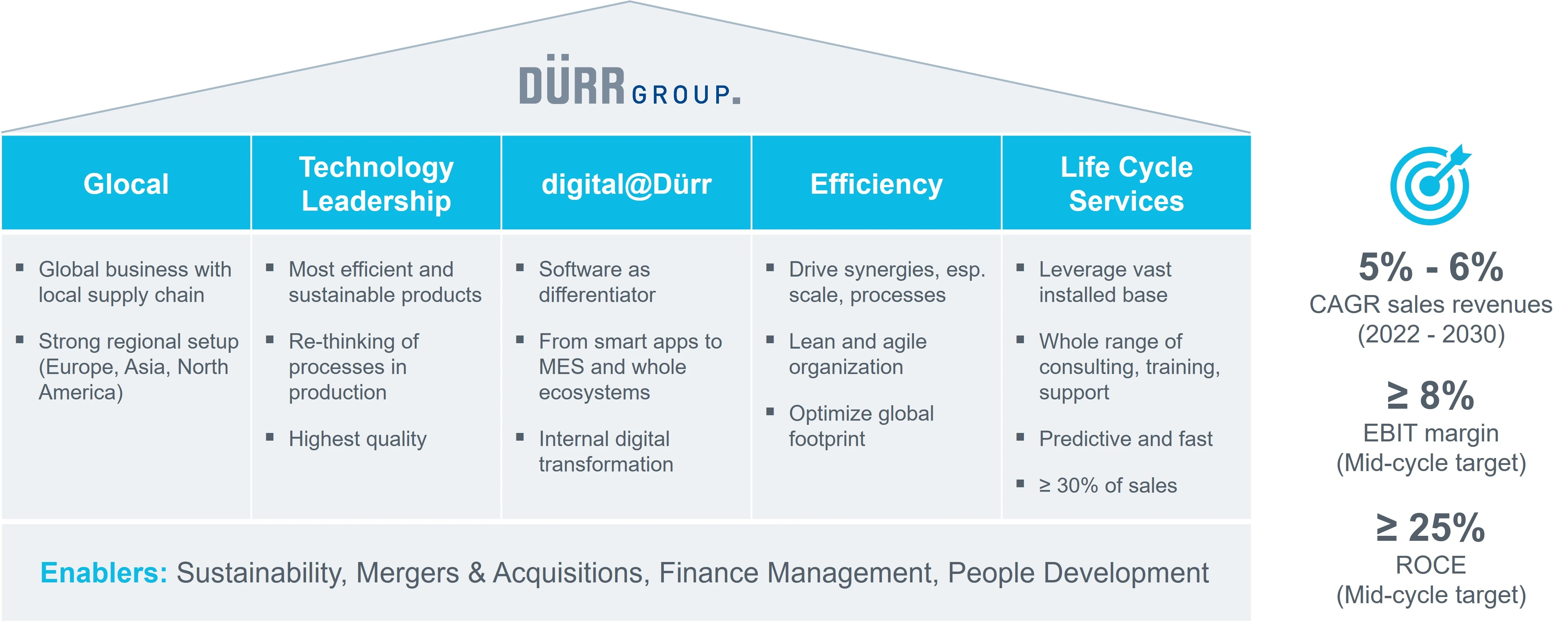

Our strategy includes several KPI targets that extend until 2030:

- 5 to 6% sales growth: Sales are to grow by an average of 5% to 6% per year between 2023 and 2030, reaching more than €6 billion in 2030.

- High profitability: The EBIT margin before extraordinary effects is to widen to at least 8%. This is a mid-cycle target, achievement of which is predicated on normal market conditions free of any major dislocations.

- Attractive return on capital: We are aiming for an ROCE of at least 25%. This is also a mid-cycle target. Underlying drivers are the high EBIT contributions from mechanical engineering and low capital employed in plant engineering.

- Good cashflows: From 2025 onward, we are aiming for a cash conversion rate of at least 80% (free cash flow is at least 80% of earnings after tax).

- Solid balance sheet: The ratio of net financial liabilities to EBITDA should not exceed 2.0.

- Increased share of service business: With its higher margins, service business is to consistently contribute at least 30% to Group sales.

Strategic Fields and Enablers

We have identified five strategic fields that are critical for achieving our goals and expanding our leadership in the global market: glocal (global/local), technology leadership, digitalization, efficiency, and life cycle services. We have also defined four enablers, i.e. supporting functions, which are particularly important for the successful implementation of the strategy. These are sustainability management, mergers & acquisitions, finance management, and people development.