When a simple “spot repair” is inappropriate, a full repair job is called for. Usually, after sanding of the defective areas, an intricate process follows, whereby the paint is sanded down manually, before a new paint finish can be applied. The sanding operation is particularly problematic, as it is extremely time consuming and, because it is carried out manually, quality fluctuates. Where the geometry of the body is complex, it is not always possible to sand down all areas satisfactorily and points that are sanded down too far have to be built up again with primer. The dust produced during sanding also affects quality.

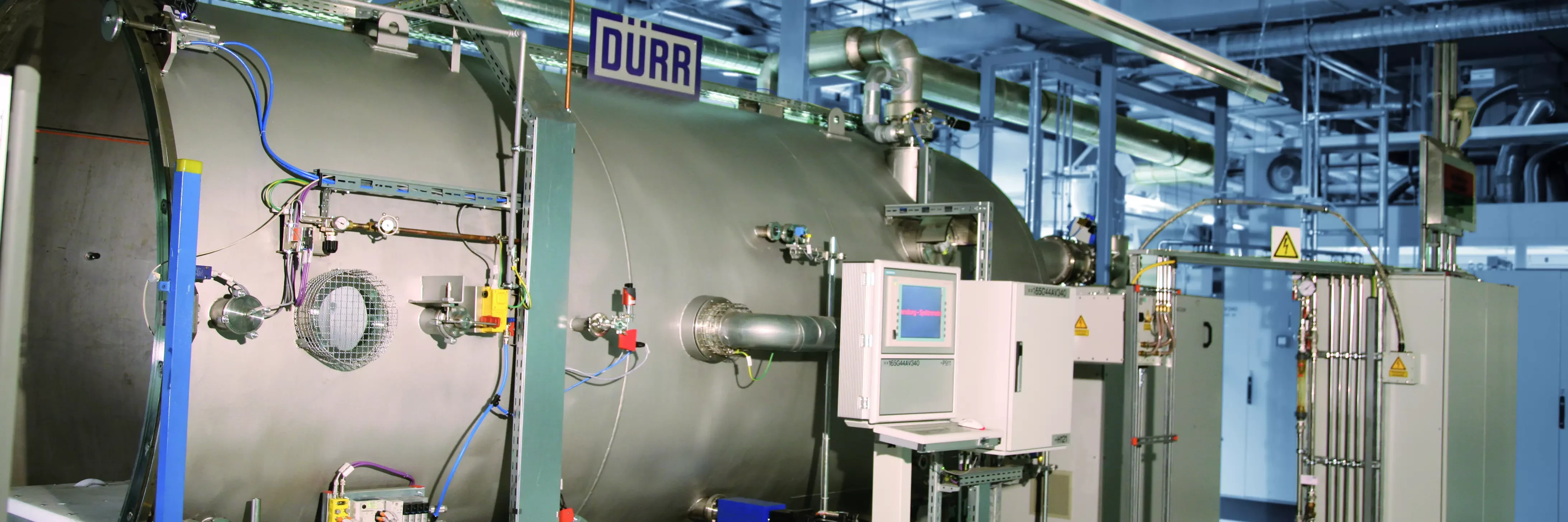

One solution is plasma activation. Here, the surface is treated in such a way that it can be painted without the need for general sanding. A system of this kind has been built by Dürr for an auto manufacturer in Southern Germany. The body is connected to an electrical oscillator in a vacuum chamber. Activation of the body surface is achieved via oxygen plasma. After air evacuation process gas is led into the chamber, then the plasma is ignited via a high frequency generator. The alternating current flowing through the body generates oscillating magnetic fields that activate the plasma. As a result polar ester groups are formed on the surface in the primer paint. They increase surface tension and improve cross-linking and bonding characteristics. The process takes around 90 seconds. The body is then returned to the spray booth for repainting.

This fully automatic process reduces the time required for repair sanding operations by approximately 70% so that the cycle time for the complete repair process is less than ten minutes. In addition, plasma activation leads to consistently good bonding results, reproducible paint adhesion and, through the elimination of sanding dust, to better quality.