Drying and Curing

Dürr continues to pioneer the engineering and development of non-contact flotation dryers and ovens for roll-to-roll drying and curing. 50+ years of experience of the former brand Dürr Megtec, more than 100 patents, and thousands of dryer installations worldwide confirm its leadership position as a world-class supplier of drying and curing systems for industrial applications.

Drying and Curing Solutions

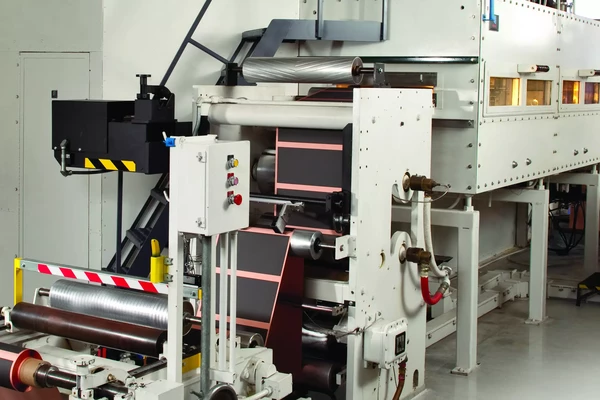

Our drying and curing technologies include custom designed and built dryers and ovens for traditional converting markets, as well as in emerging markets for roll-to-roll curing of new and advanced materials. These solutions can include convection air, infrared, UV, or a combination of technologies. In addition, for applications like lithium-ion battery electrode coating, Dürr supplies complete coating lines.

In the traditional graphic arts printing industry, Dürr pioneered drying and conditioning equipment, as well as web-handling and splicing equipment. As such, it is long-recognized as a global leader with thousands of installations on newspaper, magazine, commercial, and book printing presses using drying and curing technologies, including convection dryers, UV drying and curing, and infrared dryers. Today, Dürr leverages this engineering heritage in the digital printing market.

Process Development Services

To support the development of specialized and proprietary coating and drying applications, Dürr has an in-house Development Center located at its facility in De Pere, Wisconsin, USA. The Center features world-class laboratory bench-top tools and a complete roll-to-roll pilot coating that can be rented.

Benefits of the technology

The Dürr in-house pilot coating line enables customers to test, develop and improve web-based processes by evaluating system variables and components without having to invest in full-scale production. The goal is to optimize coating, substrate performance, and web-based operation to shorten the time between trial and commercialization.

The pilot coating line is fully equipped - from mixing to coating, drying to rewind. The system is engineered to allow for translation of the bench-top results to production-ready processes, confirm predictions of drying process models, and solve the most challenging coating and drying process problems.

The pilot coater is an important factor in establishing the viability of emerging and advanced materials applications. It can help confirm the potential for technology patents by providing a highly confidential environment needed for new-product development. It’s also the ideal environment to produce prototype materials for further research, marketing, and quality testing.