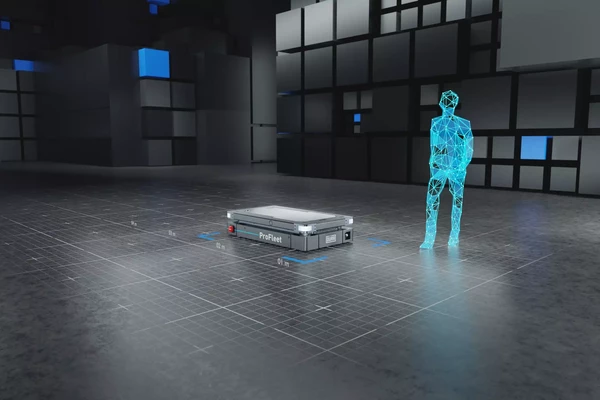

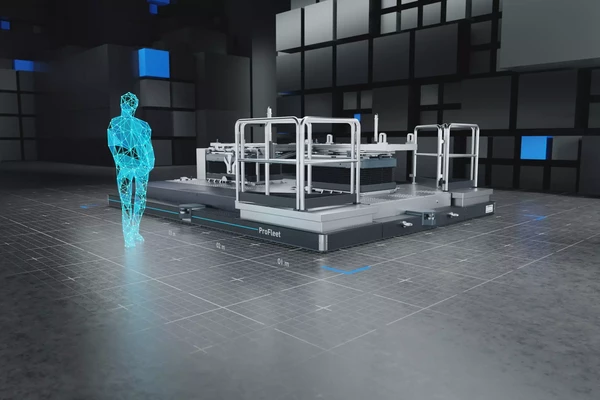

ProFleet - Automated guided vehicles (AGVs)

Dürr offers a broad portfolio of high-performance automated guided vehicles. Take a look, contact us and benefit from first-class designed, robust AGVs for sustainable and efficient production in your plant.

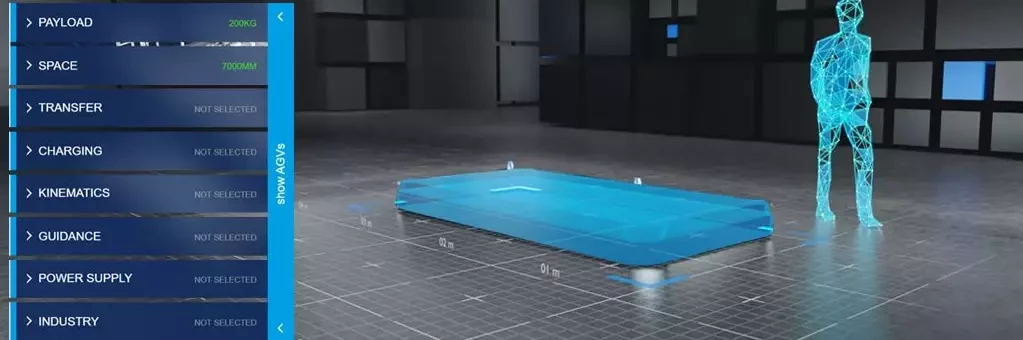

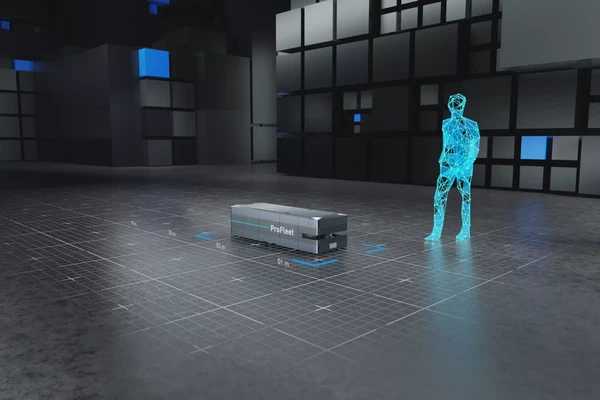

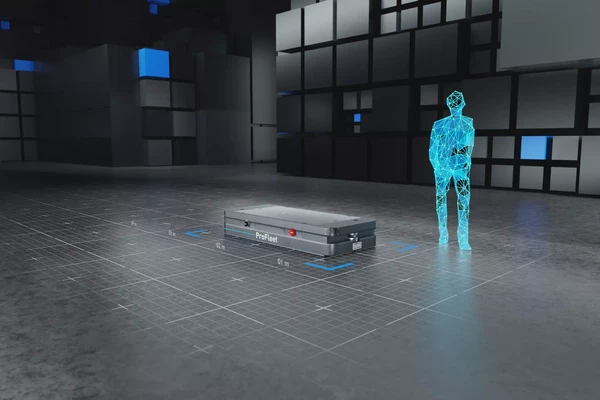

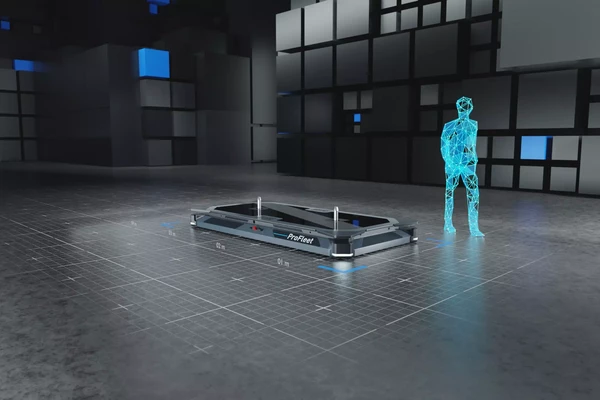

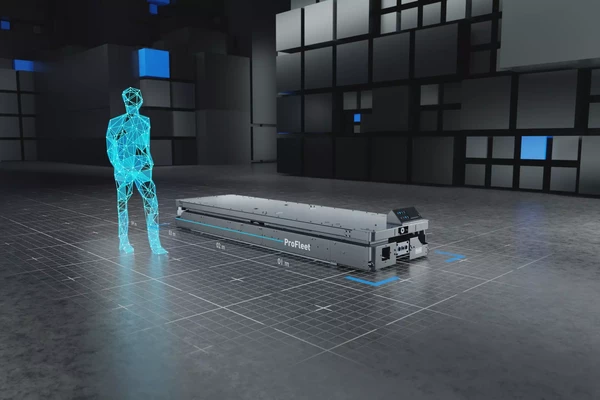

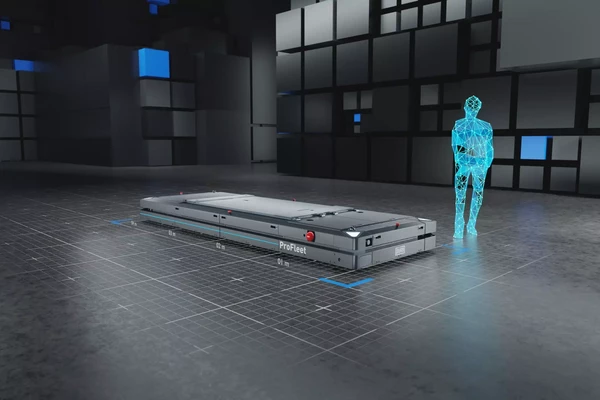

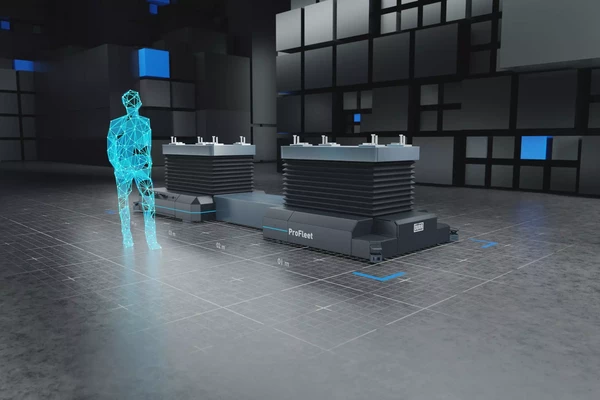

Production processes need flexibility and precision. Automated guided vehicles represent this combination in an optimal way, with the advantage of allocating a limited initial investment that can be scaled up over time and at any time, if necessary. This is where Dürr’s ProFleet AGVs come into play: Precisely tailored to each workpiece, AGVs help increase efficiency in the process chain. With optimized travel times and smart control, they offer individual solutions for individual requirements, regardless of workload or process.

With their 360° maneuverability, ProFleet AGVs replace fixed conveyor technology and create new possibilities for layout in production. And not only in the automotive industry, but also in pharmaceuticals, textiles, paper, food & beverage, home appliances, for indoor and outdoor tasks. Fully automated processes and graduated payloads paired with lifting functions as needed. Everything is possible and feasible. Agile freely navigable fleets, changing production concepts for all workpieces – small or large, heavy or light.

All ProFleet AGVs

- are equipped with Siemens open software architecture

- lend themselves to OTA technology (Over-The-Air updates)

- include a high number of market parts

- recharge via wireless charging systems installed along their path

- provide a high degree of security (performance level D)

- meet the strictest standards in terms of ergonomics

- are extremely easy to maintain

- are DXQready

DXQlogistics.control

The DXQlogistics.control stands for modularity, flexibility and scalability. Dürr’s intelligent software solution is tailor-made for the control logic of AGVs. The so-called AGV transport control module coordinates the material flow based on workload, equipment and availability of the work stations. The software can easily be enhanced and extended in three different stages in order to fit the customers’ requirements. As part of the so-called “best” case, and thus the most innovative expansion stage, the software independently selects the optimal target location. This takes into account the current work order, the defined process steps of the car body type, and the availability of the workstations. The software plans transport in advance and hence avoids unproductive breaks and cycle time losses, while ensuring production efficiency.