Paint shops for aluminum wheels – Brilliance in detail

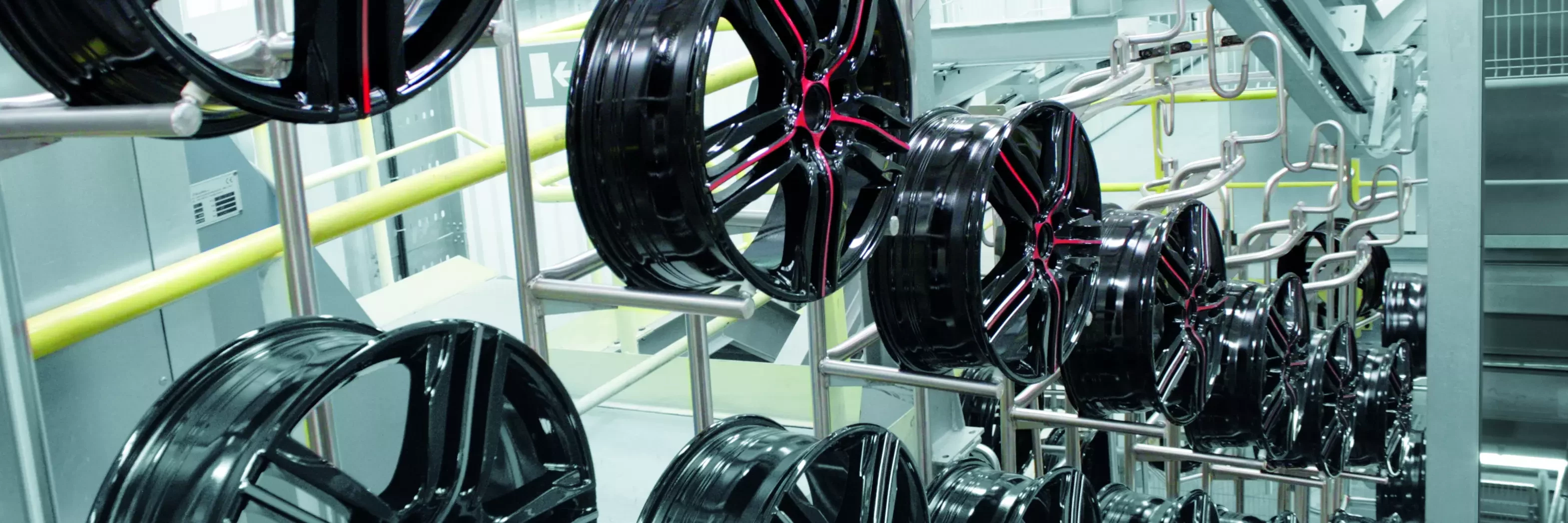

Polished aluminum wheels are very popular with end customers, but producing them often requires a special process sequence. Using a diamond blade after the painting process makes the rims look stunning. Once the material has been bright-turned, another clear coat is applied to protect the finished surface.

Dürr provides end-to-end, customized turnkey paint shop solutions for aluminum wheels, from cleaning and chemical conversion for effective corrosion protection through painting and curing to air pollution control.

Dürr-Group companies Olpidürr and Verind, both Italian subsidiaries, are centers of excellence in aluminum wheel painting. They have a worldwide reputation for comprehensive system integration and high-end application technology.

Our aluminum wheel painting portfolio includes

- Tailored greenfield and brownfield plants

- Comprehensive process expertise and high-quality technologies:

- CFD simulation and initial concept planning

- Pretreatment and dip coating

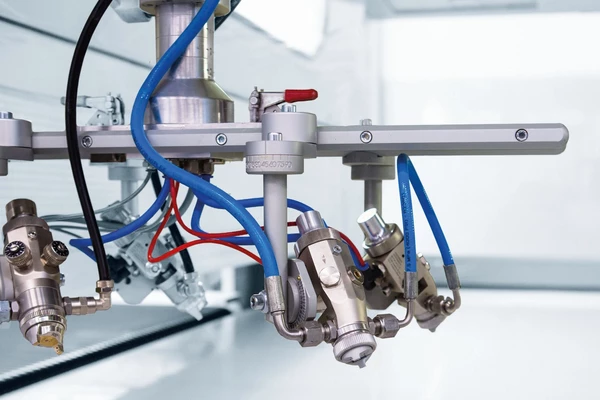

- Spray booths and robot application systems

- Oven systems

- Conveyor systems

- High-performance automatic control and digital connection

- Air pollution control

- Professional implementation and start-up management

- Spare parts service, inspection and maintenance

- Service locations worldwide