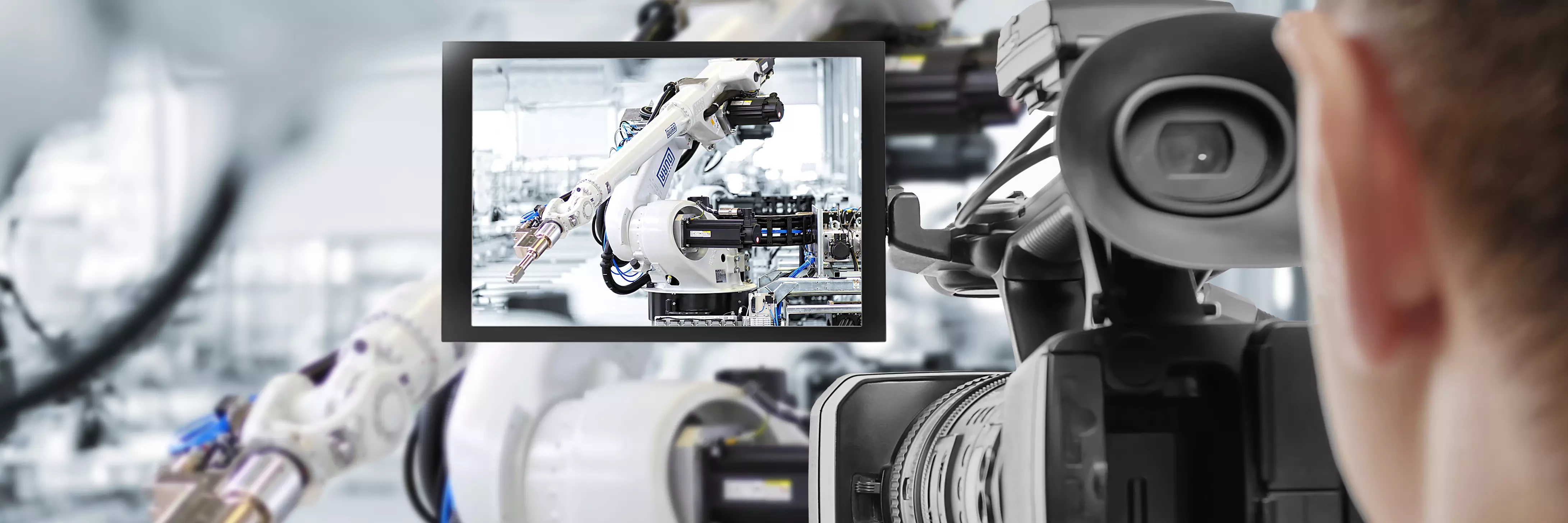

Press photos and movies of Dürr

Terms of use relating to images and movies of Dürr

All images are protected by copyright. Dürr is the holder of all rights of use, without exception.

The images may not be modified and may be used exclusively for purposes of editorial reporting but not for commercial purposes such as advertising/marketing and trade. The reference “Image source: Dürr” must be added to any publication.

If you have questions about the use of the pictures, please contact us. If images are desired to be used for purposes other than reporting or if modifications to our images are desired, permission must be obtained in advance.

Downloads

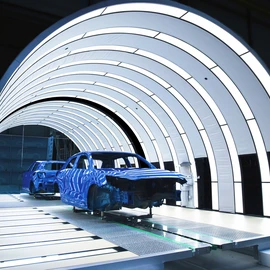

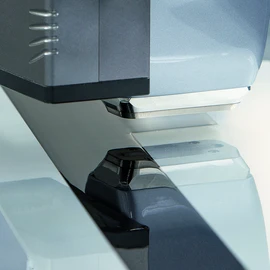

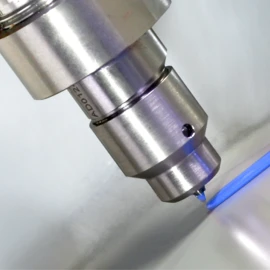

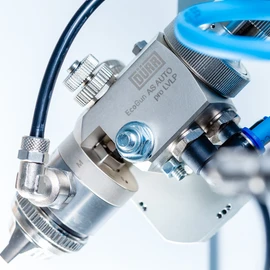

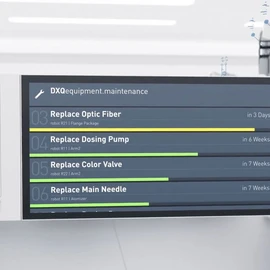

Dürr has developed a highly efficient adapter for filling air conditioning systems. Not only does it operate at a much higher filling speed, but it also reduces the amount of refrigerant remaining in the adapter after the filling process by up to 80%. As a result a much smaller amount of hydrocarbon-bearing material needs to be used. This helps to cut material costs - and on top of this reduces emissions to the environment.

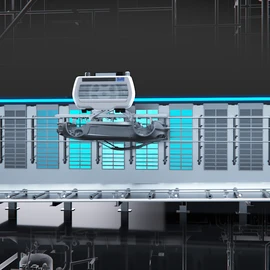

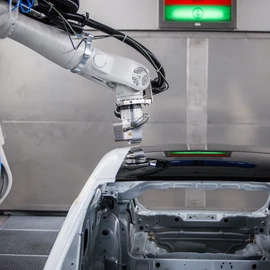

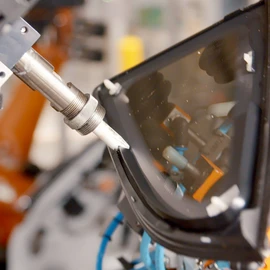

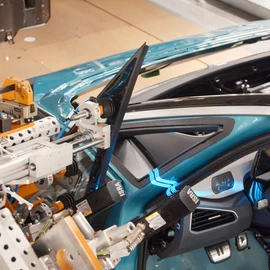

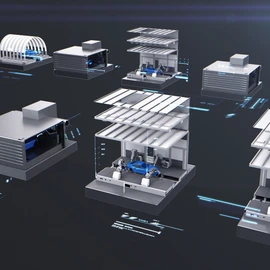

The Vehicle-in-the-Loop setup for ADAS or autonomous driving function tests using over-the-air stimulation. For the first time, the unique concept enables fast, contactless, and reproducible ADAS/AD functional tests on complete, unmodified vehicles using a virtual traffic environment in a controlled and safe setting.

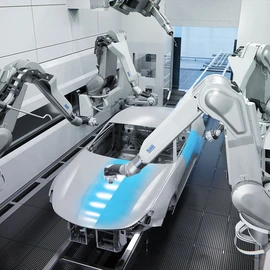

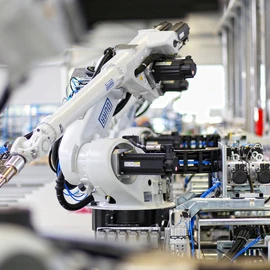

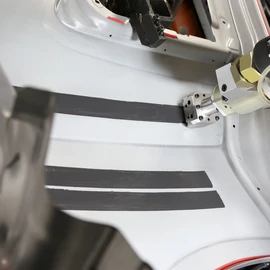

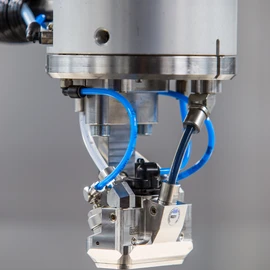

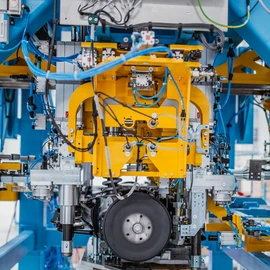

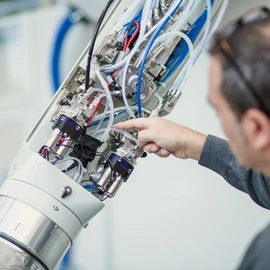

The automatic bolt picking and loading system x-elect for the fields of automation and final assembly. With the help of a 3D camera system and intelligent image processing software, the bolts are removed directly from the transport boxes and automatically brought to the defined transfer position for further processing in the bolting process.

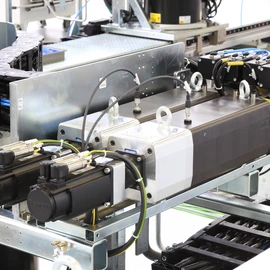

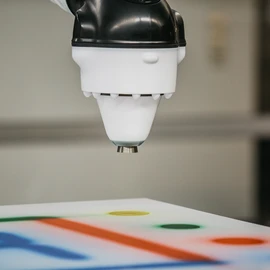

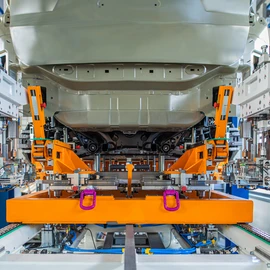

The optical steering wheel balancer for precise and reliable measurement of the steering wheel position for automated test stands or automated vehicles. The measurement of the steering wheel angle during the chassis measurement and adjustment is carried out using a 3D camera and software specially developed for this application.

Footage

You are interested in any footage?

Please have a closer look on our YouTube channel and let us know, how we can support you.

DÜRR YOUTUBE CHANNEL

Media Contact

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany