Innovation as a mission

Jan 26, 2023

How Dürr is helping to shape the future of final assembly with

With the concept of the paint shop of the future, Dürr proves how visionary ideas can be married with state-of-the-art technology. At the NEXT.assembly Innovation Summit, Dürr presented the innovative idea of the final assembly of the future for the first time in October 2022. In this interview, Andreas Hohmann, Vice President NEXT.assembly and Managing Director CPM, talks about current challenges, gives us an insight into promising final assembly solutions, and explains how all of this will benefit customers.

What challenges and opportunities do you see in the market in the area of final assembly?

Mr. Hohmann: These are exciting times. We know that the sector has been changing for years; we are the experts who are driving the transformation in final assembly, and we turn challenges into opportunities.

Even long before Covid, higher product diversity with new vehicle architectures and shorter times to market was a challenge. We are seeing ever-increasing demands to transform existing brownfields into EV-ready final assembly facilities. In addition, we are currently observing bottlenecks in the market. Supply chains are being increasingly weakened by material shortages as well as delivery delays and must be made more resilient.

The speed with which new vehicle concepts can be integrated into existing systems will make a significant contribution to the success here.

Do you have a specific example?

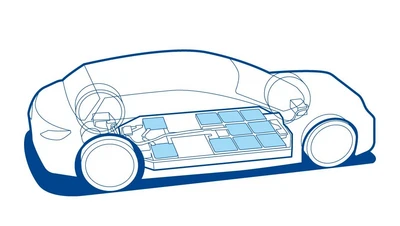

Mr. Hohmann: Yes, the latest generation of battery-powered vehicles and driver assistance systems is posing particular challenges.

For example, we expect additional inspection scopes in the EoL area for them. The development of heavy cast aluminum bodies means that joining and gluing processes are now taking place during final assembly. It will also be exciting to see how hydrogen-powered vehicles are integrated into automotive final assembly. Our team at Dürr Consulting are already conducting initial trials.

Are there regional differences?

Mr. Hohmann: If you look at regional challenges, it becomes clear that the percentage of EV-ready plants in the NAFTA region is not yet high enough. This percentage will be further expanded in the future. China has built up lots of new production capacity for battery-powered vehicles in recent years. Currently we are therefore seeing an increasing significance in the brownfield environment.

In Europe, the picture is the opposite: The retrofitting of existing plants is already well advanced, and the need for greenfields to extend production capacity is growing.

How can Dürr help?

Mr. Hohmann: First, Dürr is and always has been an engineering pioneer. We are a market leader in paint shops and in final assembly. For over 40 years, we have been a successful and reliable partner in final assembly and have constantly improved and extended our product portfolio.

One of the big drivers for this, alongside electric mobility, was and is automated driving with its levels one to five.

New vehicle architectures and a higher mix of variants are changing the processes in final assembly, and thus opening new production concepts. The variety of vehicle integrations into new as well as existing systems requires reliable partners with extensive technical expertise in final assembly, and competence in global project management.

We have the biggest and most innovative offering for final assembly on the market. Supporting customers right from the early phase is in our DNA.

Together with our customers, we develop ideas, conduct feasibility studies, ensure a reliable retrofitting of brownfield plants, and supply complete assembly systems including digital applications. In short, we supply solutions.

And last but not least, we also handle the technical integration of third-party solutions. This makes us a one-stop-shop partner for our customers.

What do you have to say to the operators of final assembly systems?

Mr. Hohmann: Three things. Most importantly: We have a proven track record. Dürr is 100 % reliable.

Secondly: Be open and work with us. Let us build a team and find the best solution for your final assembly that is up to the challenges of EV integration, preparing for autonomous driving, and increasing OEE through digitization.

The third point is as important as the first: We have a professional service network whenever and wherever you need us, and are just a stone’s throw away from your plant.

And allow me to finish with a request: We would very much like to speak to you about the digitization of your final assembly and find out how you can benefit from our digital solutions. We have created solutions for your next challenge, and are able to tailor them to your needs.