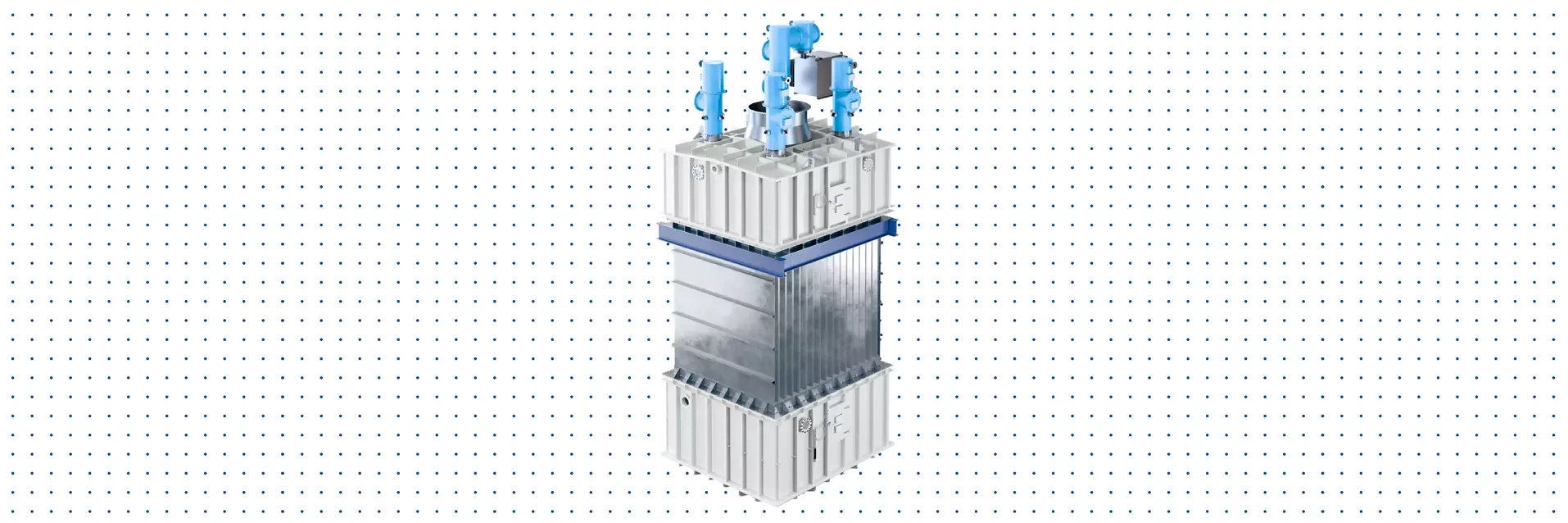

Part.X PW – Acid Mist Precipitator

Dürr’s Part.X PW acid mist wet electrostatic precipitator (WESP) provides high-efficiency removal of acid mist and particulate in sulfuric acid plant gas cleaning applications. It offers a single-stage efficiency of up to 95% (acid mist), and a two-stage efficiency of up to 99.75% (acid mist).

Part.X Acid Mist Precipitator Benefits

The robust, all-alloy construction of the Part.X PW acid mist WESP offers many benefits, including:

- Non-flammable

- Adept at withstanding high-pressure cleaning without harm; especially appropriate for smelting processes in which WESP scaling is a consideration

- Low maintenance; no bolted process connections that may leak; alloy units feature seal-welded joints

- Capable of tolerating temperature and pressure excursions

- Positive grounding offers more consistent performance and enhanced safety; fogging nozzles not required to provide conduction path

- Material can manage ideal spark rates for highest performance

Part.X PW Acid Mist Precipitator Operating Principle

The gas typically enters the bottom of the acid mist WESP. A gas flow distributor in the inlet plenum ensures optimum gas flow distribution across the collecting tubes. Discharge electrodes, mounted on a high-voltage frame, electrically charge the incoming contaminants (solids, acid mists and/or aerosols) for collection on the collecting tubes. From there, the cleaned gas is discharged from the WESP system. A washing system sprays water to periodically clean the WESP interior for optimal collection efficiency.

An option for top inlet/outlet WESPs with an internal downcomer is also available, especially for existing applications in which existing ductwork is reused. Top inlet WESPs are available for two-stage upflow/downflow configurations.

The Part.X PW for acid mist also features hexagonal tubular collecting electrodes and rigid mast discharge electrodes with fixed frame design. The transformer/rectifiers are available in conventional single phase, high-performance three phase, high-frequency SMPS.

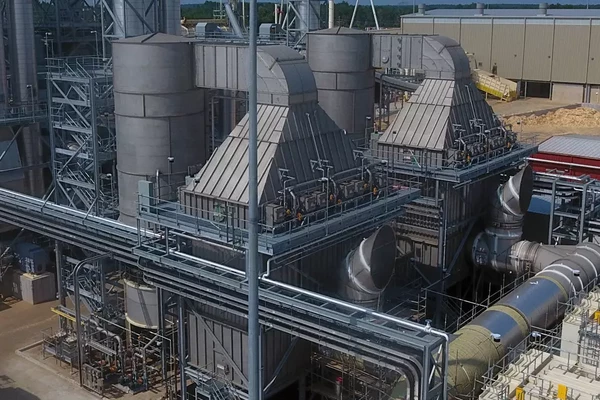

Part.X PW Application Areas

The acid mist precipitator is best suited for acid plant gas cleaning of dirty, off-gas process streams from:

- Nickel and copper smelters

- Zinc and lead roasters

- Sulfuric acid regeneration

- High purity acid applications