Treatment and processing of wood gives rise to different emissions. The main pollutants are wood dust, volatile organic compounds (VOCs) and hydrocarbons. For many years Megtec’s core expertise has been the effective control of VOCs and hazardous air pollutants (HAPs) from dryers and press vents in the engineered wood products industry. With the newly expanded range of environmental solutions, Dürr now provides an even stronger global platform for serving customers. At LIGNA, Dürr will present its expanded suite of environmental control technologies and services needed for this industry.

99% hazardous exhaust control

Regenerative thermal and catalytic oxidizers control VOCs and HAPs. Dürr’s CleanSwitch® regenerative thermal oxidizer (RTO) is a highly efficient solution for VOC destruction. It has an annihilation efficiency of 99% or more and a thermal efficiency of 95 to 97%. The successful deployment of CleanSwitch® in a yellow pine OSB dryer application in Southern USA has delivered a VOC destruction efficiency up to 99%. The product properties are the very latest, well matched to the highest standards and guarantee durability. Alkali-resistant heat exchange media and corrosion-resistant materials of construction match the specific application and help maximize uptime and equipment life. The engineered ceramic heat recovery beds offer a low-pressure drop and excellent bed-washing characteristics. The electric motor valve drive provides quiet operation and is reliable in virtually all climate conditions. In addition, the modular construction minimizes installation time.

High reliability and performance

The venturi and cyclonic pre-scrubber designs from Dürr ensure water saturation of exhaust stream, as well as achieving considerable removal of coarse filterable particulates. This step is important in many applications to reduce particulate build-up on the connecting ductwork and downstream wet ESP. The wet ESP can, therefore, operate at a higher corona power for improved collection efficiency. Pre-cleaning of coarse particulates allows for a longer period between washdowns.

A dry ESP is used in the control of particulates on biomass-based heat generators. Additional particulate control is provided by pulse jet fabric filters (baghouses) and cyclonic dust collectors. This ESP of Dürr has high reliability and performance, a design utilizing proven collector-plate designs, rigid discharge electrodes, and top-mounted electrically driven, externally maintainable collector and discharge electrode rappers.

Integrated solution

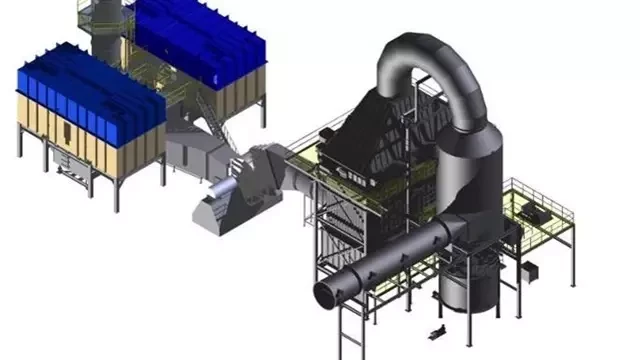

Together with Megtec, Dürr’s environmental control solutions include turnkey installations as well as equipment rebuilds, upgrades, preventive maintenance programs and energy optimization services. The company has installed thousands of easy to use and clean oxidizer systems in many process industries across the globe. It is also experienced in engineering and service for exhaust air-purification systems, including those from other manufacturers. Dürr leverages its process knowledge and technology capabilities to deliver an integrated solution for dryers with a complete system including scrubber, wet ESP and RTO.

“With our broader geographic reach, expanded product portfolio, and increased base of skilled field technicians, the joining together of Dürr and Megtec makes it possible for us to be even closer to our customers in the engineered wood products industry,” said Rodney Schwartz, Vice President Sales and Business Development of Dürr’s environmental technology division in the Americas. “Delivering responsive service is critical for our customers. With short response times and fast solutions, we make a decisive contribution to ensuring that our customers' equipment is up and running all day, every day.”

Dürr will present its air-pollution control technologies at LIGNA in Hanover, Germany, from May 27th to May 31st in hall 26, booth D08/2. As a further part of the company's products, Dürr will also present its application technology for painting in the wood industry. It will be exhibited in hall 14 at the booth of HOMAG, the world market leader for machinery and equipment for the woodworking industry, which is part of the Dürr Group.