Compliance with new regulation

Since the beginning of 2018, a new environmental regulation in South Korea has been mandating shipbuilding companies to treat the exhaust air from paint shops. According to the new rule, 20% of the total paint shop exhausts air flowrate need to be treated in 2019, and by 2022 the target is to combat a full 100%. The installation of the HAPs treatment facility at the shipbuilding company’s painting facility in South Gyeongsang Province took eight months and was successfully completed in December 2018. With the Dürr Ecopure® CRC and RTO system, the shipbuilding giant is now able to reduce its HAPs to a concentration of below 100 ppm. This is a decrease of more than 90% of the HAP emissions and is in compliance with the country’s domestic Clean Air Conservation Act.

Energy saver

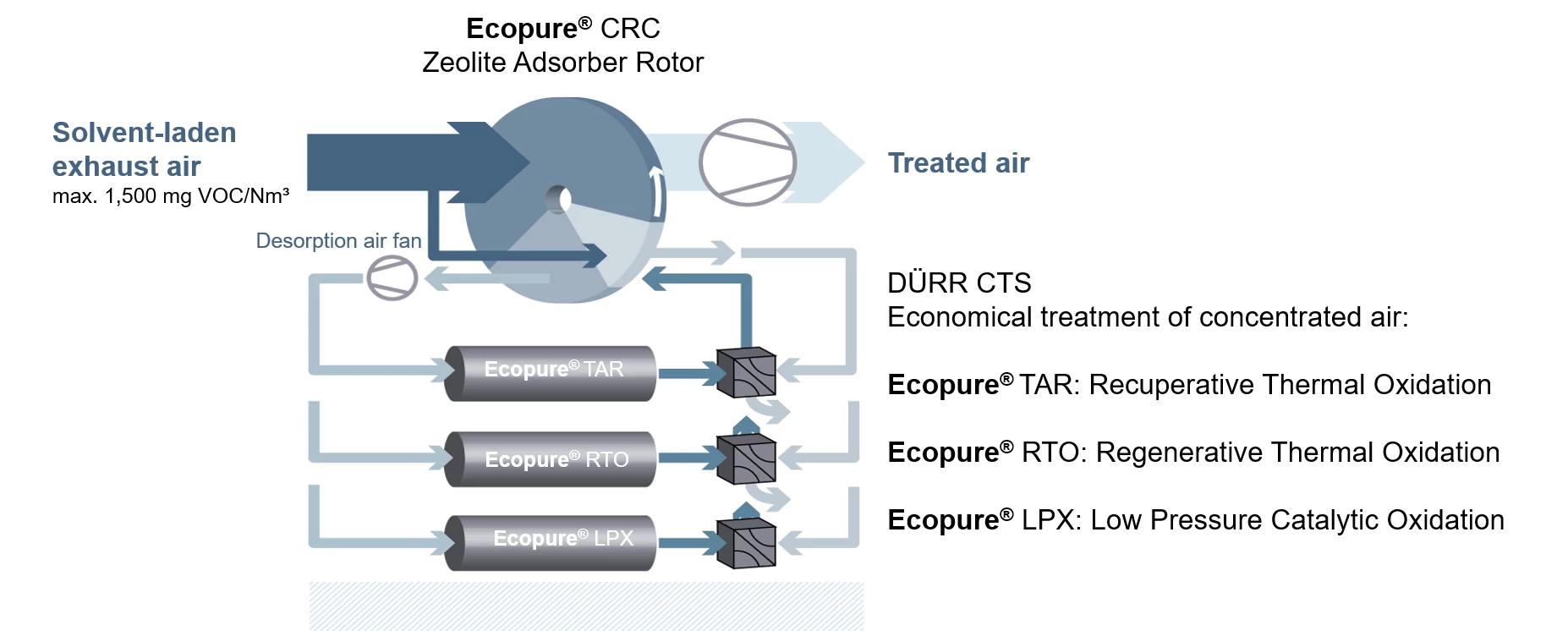

The anti-pollution control system consists of a filtering system for particulate removal, a disc concentrator system for selectively adsorbing and concentrating volatile organic compounds (VOCs), as well as a RTO combustion system that treats the small volume flow of concentrated HAPs. The RTO system provides an energy-saving technology that reduces energy consumption by 95% or more by utilizing recovering heat from a ceramic media mounted inside the RTO. In addition, the consumption of primary energy can be drastically reduced if the calorific value and concentration of the VOCs and HAPs is sufficiently high. The volume flow is 5400 ACMM and the whole building needs ventilation.

Impactful for other industries

The installation of the integrated system is a first of its kind to be built and operated in South Korea’s shipbuilding industry. The innovative new system uses a single consistent unit while others use two or more to treat the pollutants. The costs for the product are comparable with other solutions. The Ecopure® RTO system will favorably impact the shipbuilding industry along with other industries in need of clearing painting booth pollutants like VOCs and HAPs. The shipbuilding giant opted for Dürr appliances due to the group’s market credibility and legacy of similar air purification products. Two further installations for shipbuilding companies in Korea have already been ordered from Dürr in the second and third quarters of 2019. Besides Korea, this abatement system is already enjoying a successful run in China and Dürr will offer its applications to other shipbuilding companies internationally.

Dürr will showcase its complete portfolio in exhaust air purification for the shipbuilding industry as well as the company’s products in paint application at KORMARINE 2019 in Busan, South Korea, from October 22 to 25 at booth number 4Q17.