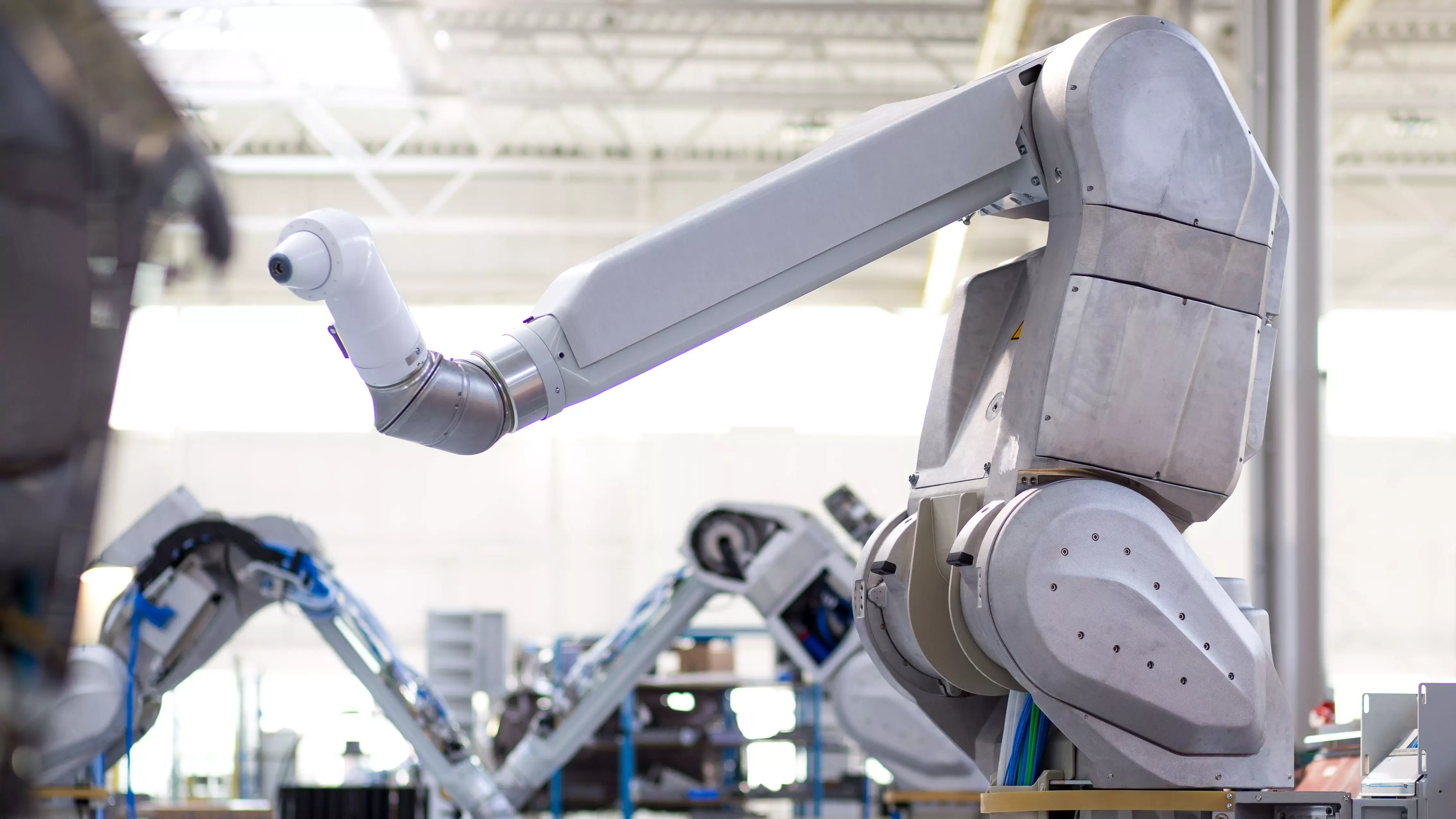

The 13,000th robot manufactured by Dürr is an EcoRP E043i, and will be used to paint the interior of passenger cars at GM in Changwon. The celebration of this specific robot is special to Dürr for many reasons: it is the first time Dürr’s new generation three robot will be used at GM. GM relies on fully automated painting with the latest application technology. The equipment for the new paint shop, which Dürr was commissioned to build, includes a total of 78 third-generation robots. The total order is also the biggest order Dürr has received to date as a general contractor in Korea. GM will put the planned plant into operation in 2021, and paint the new Chevrolet Spark as well as compact SUVs there using the 3-wet method.

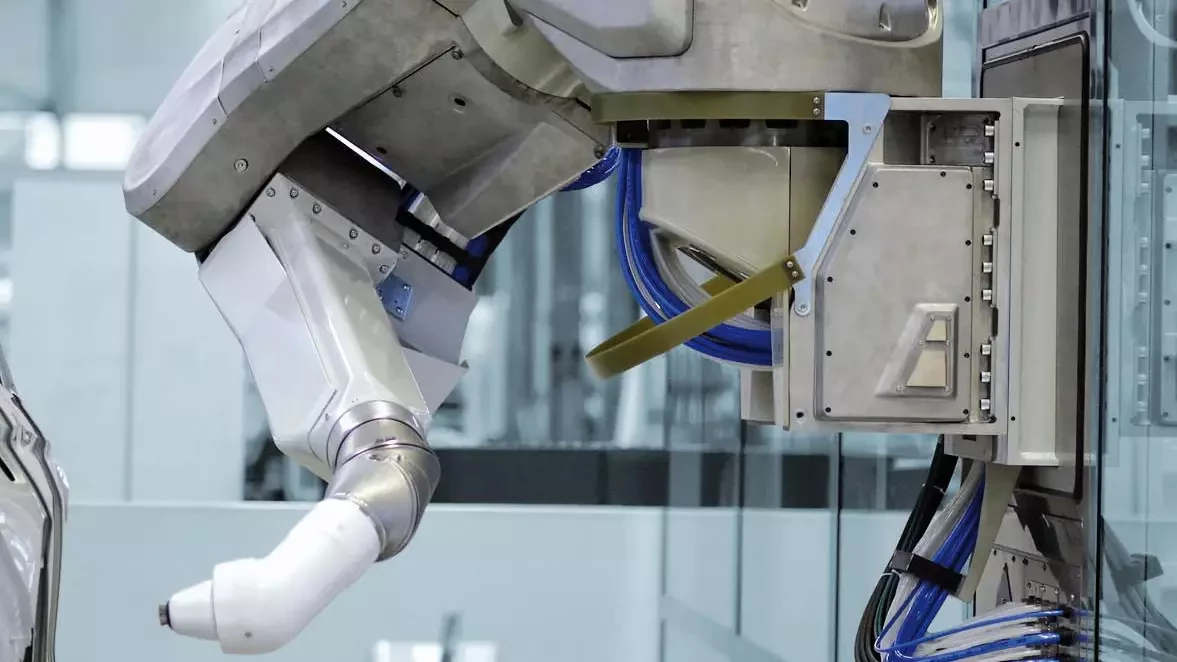

The EcoRP E043i and 033i painting robots will handle painting the interior and exterior of the car bodies in Changwon. Seven-axis robots with the latest EcoBell3 atomizer technology will paint the interiors of the vehicle bodies with extremely high precision and flexibility. Their enhanced mobility mean they can reach even difficult-to-access places effortlessly. The exteriors will be painted using six-axis robots. Dürr’s application technology, such as the EcoBell Cleaner D2 atomizer cleaner, stands for state-of-the-art processes with low VOC emissions. The interplay of the dosing pump, color changer, atomizer, and atomizer cleaner ensures fast and efficient color changes within just 15 seconds, thereby reducing paint loss and flushing agent consumption when changing color.

The solvents are removed from the exhaust air using an Ecopure® RTO regenerative thermal exhaust air purification system together with the Ecopure® CRC VOC concentrator from Dürr.

In the existing factory in Changwon, Dürr designed the plant to be over three levels with two painting lines for a total volume of 60 vehicles per hour. GM thought one step ahead when designing the plant by providing space for a later two-tone painting line.

The construction of the plant also represents Dürr’s biggest order in Korea. A decisive factor for GM was the geographical proximity. Dürr is implementing the project in close cooperation between the headquarters in Germany and the Korean subsidiary in Seoul. Having contact partners directly on site means that Dürr can provide efficient and highly qualified service locally.

“We’re proud that GM chose us for this important project. This shows the high customer benefit of the new features of the third-generation robots: top quality and availability with optimized costs,” explains Dr. Lars Friedrich, member of the Board of Management of Dürr Systems AG and responsible for the Application Technology Division.