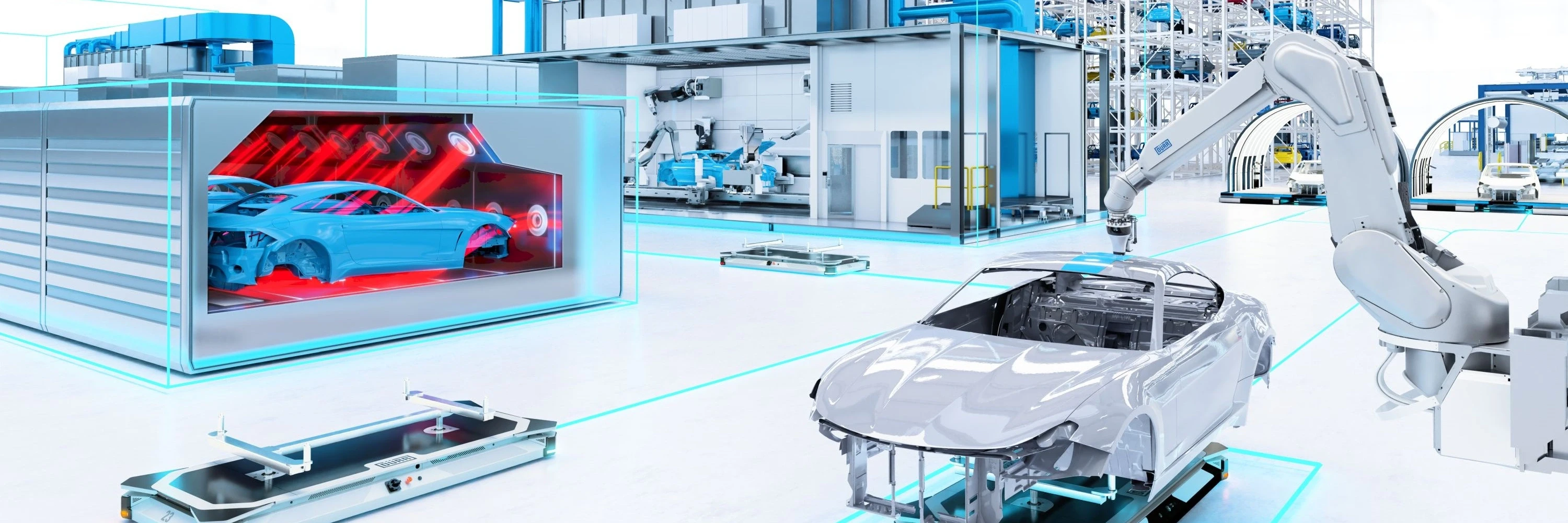

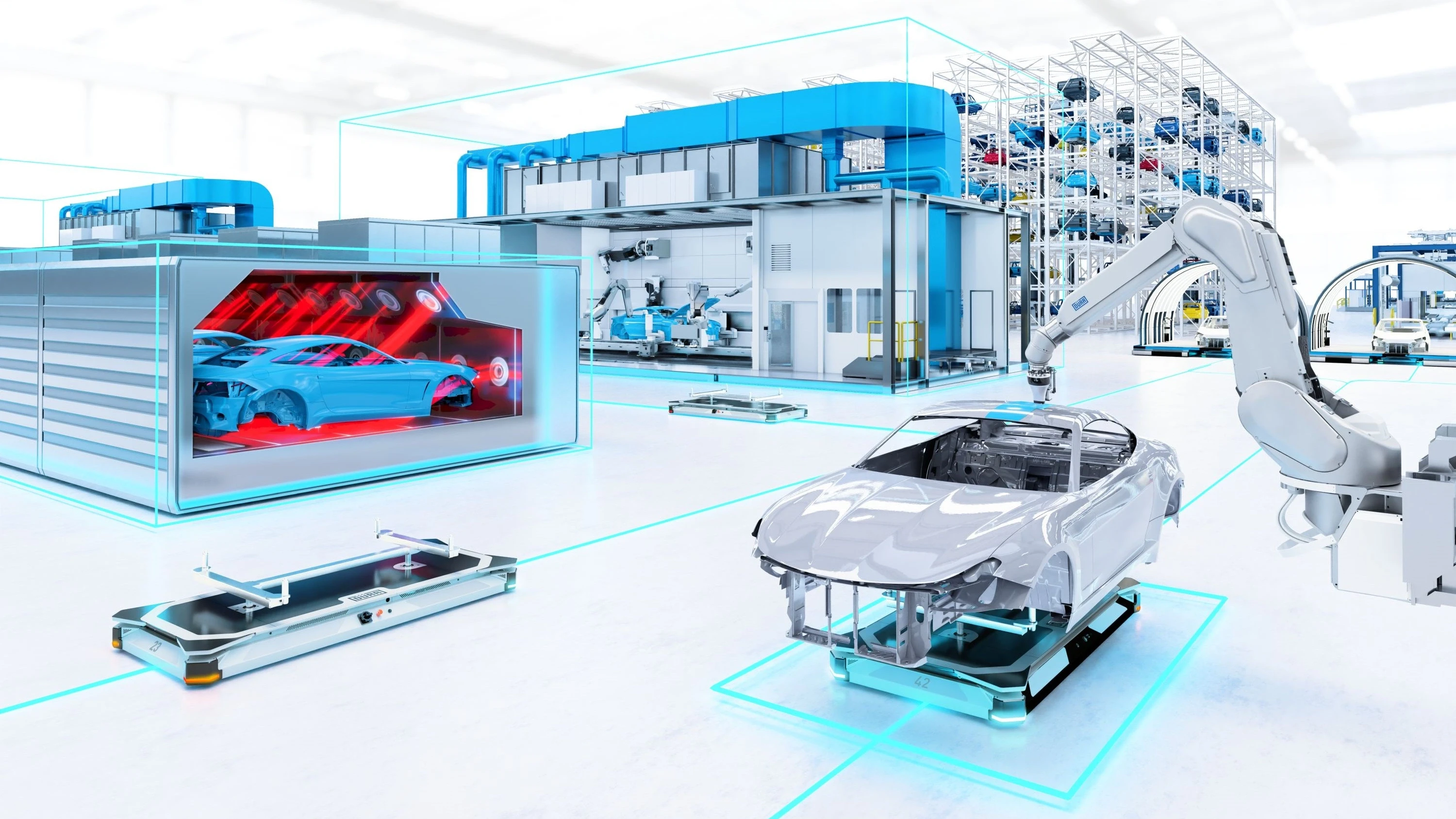

For the first time, Dürr is fully implementing its Paint Shop of the Future concept at CEER. The modular design includes the latest innovations to drive complete automation. The plant uses digital solutions from Dürr’s DXQ product family to reduce downtime and maximize systems’ efficiency. The new system at CEER Manufacturing Complex located in the King Abdullah Economic City will begin production in the fourth quarter of 2026.

Efficient high-tech products benefit the environment

CEER relies on Dürr's new generation of ovens. The EcoInCure heats the body from the inside to reach massive body components more directly. This is particularly advantageous for electric vehicles, as they require – among other things – well reinforced rocker panels to protect their batteries in the event of a side impact while simultaneously preventing overheating in thinner parts of the body shell. This drying method is more environmentally friendly, reducing the required heating process time for the body is by up to 30% compared to conventional systems. An Oxi.X RV from Dürr CTS cleans exhaust air from the oven using the principle of regenerative thermal oxidation (RTO). The oxidation reactions, which purify the process exhaust, occur entirely within the heat exchange media. Since the system operates using electricity, there is no open flame and therefore none of the unwanted by-products of flame combustion.

Another notable feature is Dürr’s EcoPaintJet Pro, an award-winning overspray-free painting system. CEER can utilize this to offer its customers cars with a two-tone paint finish. The EcoPaintJet Pro technology marries customer-specific product design with automated production. Bodies can be painted with two contrasting colors simultaneously, reducing paint consumption and eliminating plastic waste since the EcoPaintJet Pro does not require masking with adhesive tape. The system can also paint complex patterns such as lettering and logos.

“Innovation is a key driver of performance and sustainability in vehicle production. The paint shop of the future will deliver great flexibility, energy and paint efficiency, and exciting premium vehicle paint finishes,” said Dr. Lars Friedrich, CEO of Dürr Systems AG. “We are pleased to have the opportunity to partner with CEER to create one of the most modern car production lines in the world.”

Flexible box concept instead of rigid painting lines

CEER can swiftly incorporate new models and easily scale production capacity with the paint shop of the future. The key lies in implementing a modular concept, where flexible EcoProBooth boxes replace traditional lines with their rigid cycle times. In the box concept, the robots paint the interior and exterior of the car bodies in just one box. The new universal atomizer from the EcoBell4 Pro series meets the highest painting quality standards. Dürr’s EcoProFleet AGVs are constantly in motion and flexibly transport bodies between workstations and the high-bay warehouse based on demand. DXQlogistics.control, Dürr’s tailored software solution for the AGVs’ control logic, controls material flow digitally following work deck utilization, equipment, and availability.

Smart factory due to DXQ software

Digital solutions from Dürr's DXQ product family turn CEER's paint shop into an intelligent factory. The DXQcontrol modular solution is an innovative manufacturing operations management (MOM) system with a microservices architecture that delivers a high level of flexibility and consistency. The MOM comprises over 50 functionalities for manufacturing planning, execution, control, monitoring, optimization, and predictive analysis. DXQanalyze provides information based on specific systems and uses, enabling it, for example, to forecast the remaining service life of system components or to establish links between quality results and machining processes, taking transparency about the operating behavior of machines and systems to a whole new level.

“Our goal at CEER is to build a world-class manufacturing facility, setting new benchmark for efficiency and sustainability,” said James DeLuca, CEO of CEER. “This Paint Shop of the Future will place CEER at the forefront of automotive manufacturing innovation, allowing us to offer our customers in Saudi Arabia and the wider region a level of customization they have never seen before. The result will be a more environmentally friendly manufacturing process and the ability to offer customization in car colors, finishing, and intricate details that will excite the public.”

In autumn 2024, Dürr opened its subsidiary Dürr Systems Arabia LLC in Jeddah, Saudi Arabia, to further strengthen its customer relations in the region.