Images de presse et films du groupe Dürr

Conditions d'utilisation des images de presse et de films du groupe Dürr

Toutes les images sont protégées par droit d’auteur. Le détenteur de tous les droits d’utilisation est Dürr AG.

Les images ne doivent pas être modifiées et ne peuvent être utilisées qu’à des fins éditoriales, non pas à des fins commerciales, telles que la publicité / le marketing et le commerce. Toute publication doit être accompagnée de la mention « source d’image : Dürr ».

Si vous utilisez nos images, veuillez envoyer une courte notification à cette adresse. Si vous souhaitez utiliser nos images à des fins autres qu’éditoriales ou les modifier, vous devez en obtenir au préalable une autorisation.

Downloads

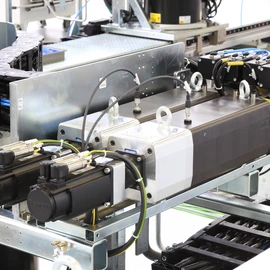

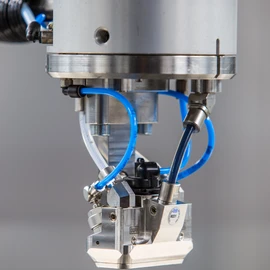

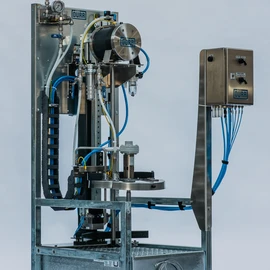

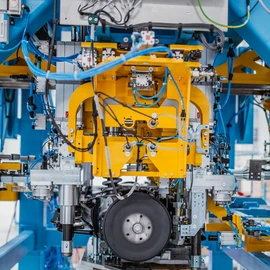

Dürr has developed a highly efficient adapter for filling air conditioning systems. Not only does it operate at a much higher filling speed, but it also reduces the amount of refrigerant remaining in the adapter after the filling process by up to 80%. As a result a much smaller amount of hydrocarbon-bearing material needs to be used. This helps to cut material costs - and on top of this reduces emissions to the environment.

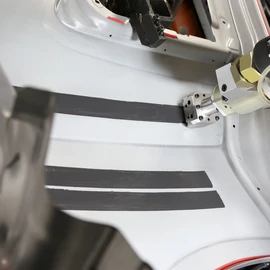

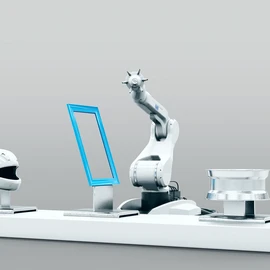

The Vehicle-in-the-Loop setup for ADAS or autonomous driving function tests using over-the-air stimulation. For the first time, the unique concept enables fast, contactless, and reproducible ADAS/AD functional tests on complete, unmodified vehicles using a virtual traffic environment in a controlled and safe setting.

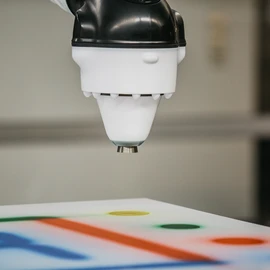

The automatic bolt picking and loading system x-elect for the fields of automation and final assembly. With the help of a 3D camera system and intelligent image processing software, the bolts are removed directly from the transport boxes and automatically brought to the defined transfer position for further processing in the bolting process.

The optical steering wheel balancer for precise and reliable measurement of the steering wheel position for automated test stands or automated vehicles. The measurement of the steering wheel angle during the chassis measurement and adjustment is carried out using a 3D camera and software specially developed for this application.

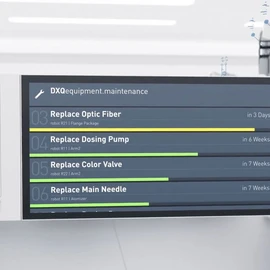

The Smart AC module within DXQequipment.analytics enables intelligent and energy-optimized control of temperature and humidity in paint booths through flexible window control, automatic setpoint suggestions, and interactive dash- boards – with the aim of achieving significant energy savings while maintaining stable process quality.

Films et autres

Vous trouverez plusieurs films sur Produits et autres Sur notre chaîne YouTube.

Contactez-nous en cas de besoin d'assistance supplémentaire.

Contact presse

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen

Allemagne

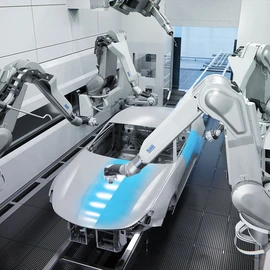

![The new generation of 7-axis robots EcoRP E043i [Translate to French:] 7-axis robots EcoRP E043i](/fileadmin/_processed_/a/e/csm_7-axis-robot-2_6e5b49a8ee.webp)

![The new generation of 7-axis robots EcoRP E043i [Translate to French:] 7-axis robots EcoRP E043i](/fileadmin/_processed_/7/5/csm_7-axis-robot-3_4bc1c19514.webp)

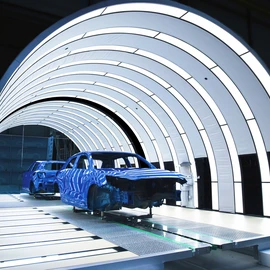

![EcoPaintJet – Overspray-free paint application [Translate to French:] EcoPaintJet paint application without any overspray](/fileadmin/_processed_/d/c/csm_duerr-ecopaintjet-1_24d6d4f634.webp)

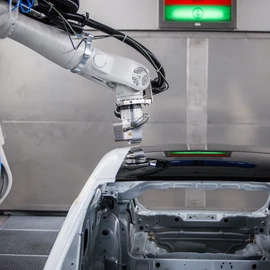

![EcoRS 30L16S [Translate to French:] EcoRS 30L16S robot suitable for sealing applications inside car bodies](/fileadmin/_processed_/0/9/csm_duerr-ecoRS-30-L16S_671a469240.webp)

![Gluing body in white [Translate to French:] duerr gluing technology body in white](/fileadmin/_processed_/6/8/csm_duerr-gluing-body-in_-white_531f989dd9.webp)

![Side window installation [Translate to French:] Side window installation and gluing at VW Zwickau](/fileadmin/_processed_/c/e/csm_duerr-gluing-vw-zwickau-seitenscheibmontage-line-tracking__5__4c039d6d44.webp)

![[Translate to French:] ProFleet 4200 with lifting ProFleet 4200 with lifting: Automated guided vehicle (AGV)](/fileadmin/_processed_/c/c/csm_duerr-cpm-profleet-010a_e1b688a454.webp)

![Side window installation [Translate to French:] Side window installation and gluing at VW Zwickau](/fileadmin/_processed_/0/8/csm_duerr-gluing-vw-zwickau-seitenscheibmontage-line-tracking__6__4e919c3ef6.webp)

![Dr. Lars Friedrich [Translate to French:] Friedrich, Lars Dr. President & CEO Application Technology](/fileadmin/_processed_/3/7/csm_duerr-dr-lars-friedrich_c91df12209.webp)

![Holger Füssel [Translate to French:] Bernd Preissler CEO Dürr Somac GmbH](/fileadmin/_processed_/0/1/csm_duerr-holger-fuessel-somac_d5e52ffc88.webp)

![Thomas Kolb [Translate to French:] Durr Testing Contact Thomas Kolb CEO Dürr Assembly Production](/fileadmin/_processed_/8/c/csm_duerr-testing-thomas-kolb_b77595e1ec.webp)