Pretreatment and electrocoating – Building a sound foundation with Ecopaint WetSystem

With the Ecopaint WetSystem product family Dürr designs, integrates and implements high-performance, top-quality wet systems with standardized components and fully coordinated conveyor systems.

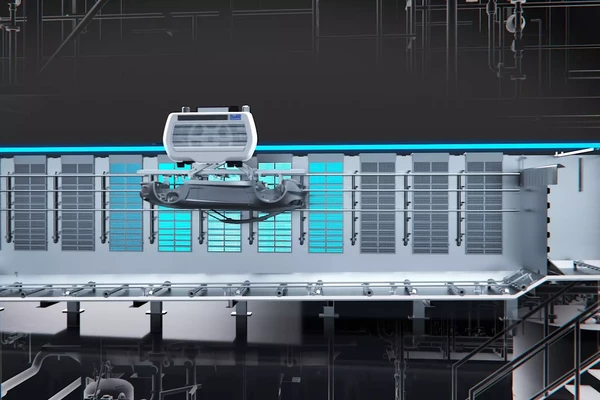

The first station in the painting process is pretreatment, where bodies coming through from the body shop are cleaned, degreased and usually phosphated to prepare them for subsequent coating. The second process step is electro-coating, which applies an anti-corrosive primer by dipping the car body in an electrically conductive bath. To ensure that also the inside is properly treated, the car body is immersed in the process bath. Pretreatment and electro-coating with Ecopaint WetSystem is based on innovative, flexible technologies.

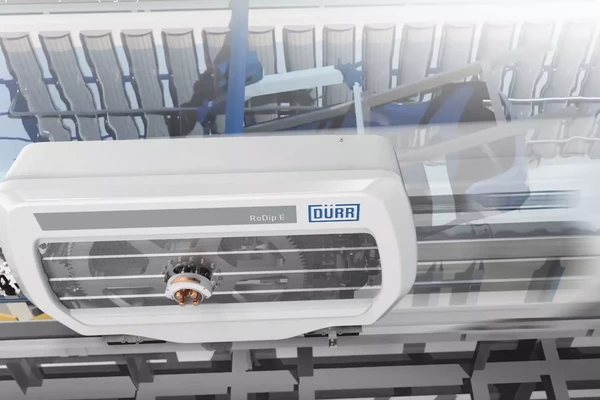

From the planning stage on, we focus on creating highly flexible wet systems with space-saving layouts and low operating expenditure. Cross-process approaches reveal untapped optimization potentials of energy consumption and coating quality. By continuously filtering the process liquids, our systems reduce both chemicals and water consumption. Our efficient RoDip® rotational dip process and optimized anode control system EcoDC MACS are just two tried-and-tested examples.