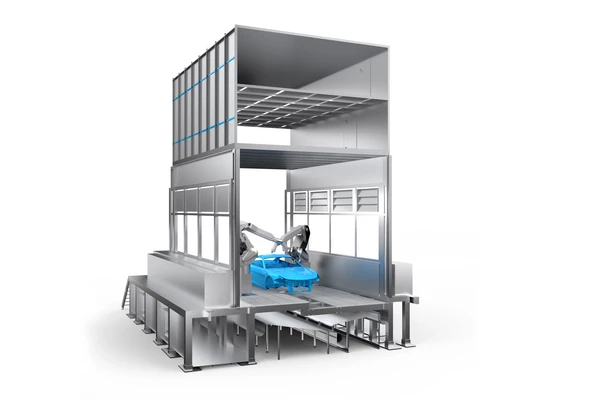

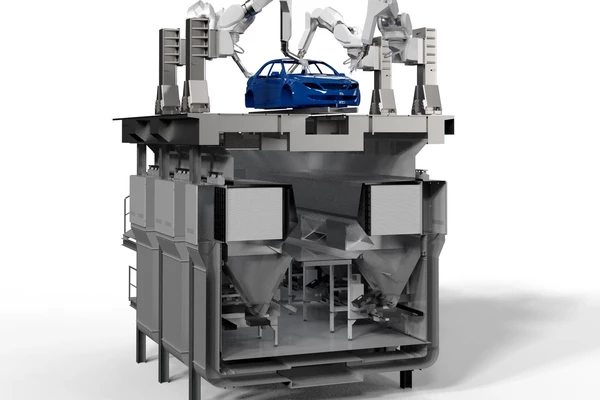

Test center spray booth

The test center spray booth serves the continuous optimization of the spray booth. Innovations such as the integration of ducts, air conditioning or recirculation systems in the cabin cross-section as well as in EcoReBooth have their origins here. Particularly in the area of dry separation, tests are carried out with innovative systems such as the EcoDryScrubber and the EcoDry X.

With the EcoReBooth Dürr offers a compact, modular booth design with excellent energy efficiency. Decisive innovations include the integration of the channels, the air conditioning and the air circulation system in the booth cross-section. This saves space and is easy to maintain. An essential component is the proven EcoDryScrubber, the dry capture of paint mist. This reduces energy consumption by up to 60% and eliminates the need for water and chemicals.

Our service portfolio

- Paint separation experiments / performance testing with real booth conditions

- Production of paint-specific material samples

- Validation of filtration additives

- Validation of new components in long-term testing

- Verification of process simulations