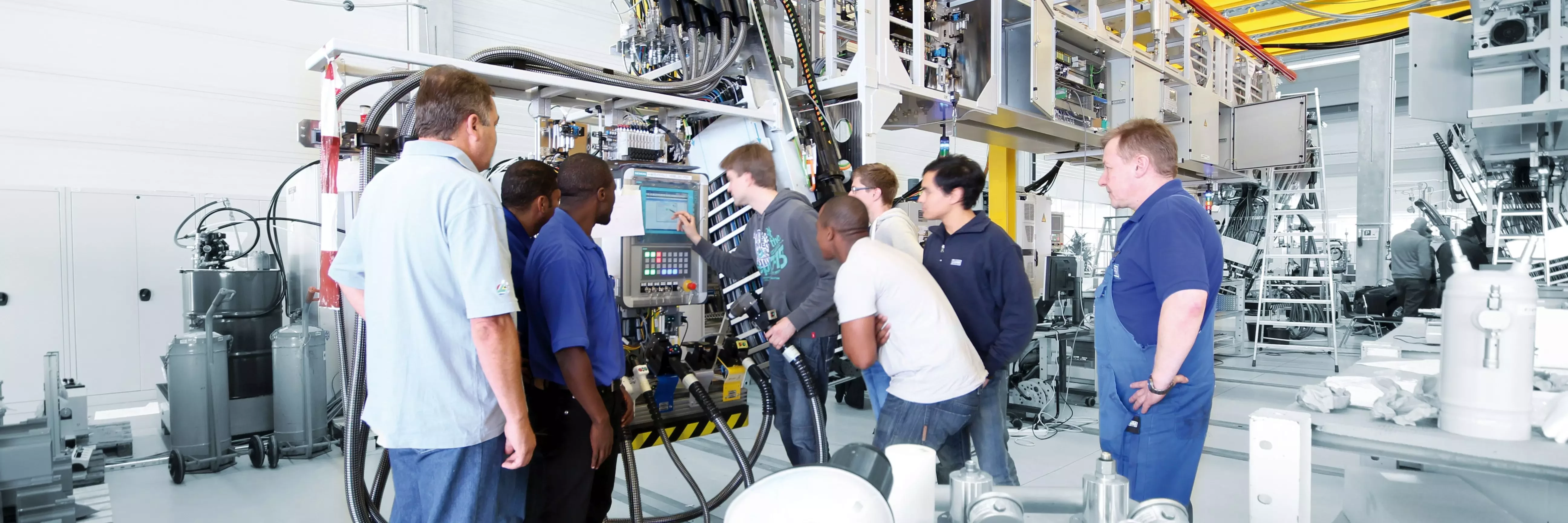

Filling Academy – Optimize your filling knowledge

The team of the Dürr Filling Academy offers a variety of training seminars either at our location in Stollberg or on-site to expand the knowledge of you and your employees in all aspects of filling technology.

Dürr provides a broad training program for your employees responsible for filling purposes and working with filling equipment. We would like to supply these employees with the necessary know-how for their work. Our training proposal includes different fields of work: The basis of filling technology, maintenance of filling equipment and diagnostics of errors in process or product.

Target – Theory Basics of Fluid Fill and Diagnosis

Content:

- Different types of filling processes

- Fluid characteristics and main components

- Media specific process design and equipment configuration

- Design, function of and preventive maintenance at modules of the filling equipment

- Process und quality assuring measures and tools

- Influences of humidity and leakages

Seminar date:

- Dates on demand | Somac® Academy Training in Stollberg or onsite at customer

- Duration 3 days | If a translator is involved the seminar length extend.

- Seminars are available in German and English.

- Webinar on demand

Target - Practice Maintenance at Filling Adapters

Content:

- Design and function of filling adapters for brake fluid, radiator fluid and air conditioning

- Practical exercises for preventive maintenance and repair

- Usage of special tools and training of required skills

- Evaluation of the condition of filling adapters during the repair works

- Training done at filling adapters of generation G3Blue and G4Blue

- Older versions and special adapters on request

Seminar date:

- Dates on demand | Somac® Academy Training in Stollberg or onsite at customer

- Duration 2 days | If a translator is involved the seminar length extend.

- Seminars are available in German and English.

- Webinar on demand

Target – Theory Special Refrigerants (C-R1234yf / C2-R744)

Content:

- Media characteristics and safety concept

- Media specific process description and function of filling adapter

- Preventive maintenance and test requirements according to pressure equipment directive

Seminar date:

- Dates on demand | Somac® Academy Training in Stollberg or onsite at customer

- Duration 1 day | If a translator is involved the seminar length extend.

- Seminars are available in German and English.

- Webinar on demand

Target - Practice Maintenance at Filling Equipment for Special Refrigerants (D1-R1234yf / D2-R744)

Content:

- Design and function of filling adapter for special refrigerants

- Practical exercises for preventive maintenance and repair

- Usage of special tools and training of required skills

- Evaluation of the condition of filling adapters during the repair works

- Usage of A/C test box to pressure test repaired adapters and clusters of the filling equipment

Seminar date:

- Dates on demand | Somac® Academy Training in Stollberg or onsite at customer

- Duration 1 day | If a translator is involved the seminar length extend.

- Seminars are available in German and English.

- Webinar on demand

Target - Theory and Practice Process Analysis at Vehicle System

Content:

- Design, components and function of the vacuum/pressure measuring box (VMK)

- Practical exercises for measurements at vehicle systems

- Data analysis according to customer requirements

- Interpretation of measuring results and derivation of measures and process parameters

Seminar date:

- Dates on demand | Somac® Academy Training in Stollberg or onsite at customer

- Duration 2 days | If a translator is involved the seminar length extend.

- Seminars are available in German and English.

- Webinar on demand

DXQeLearning Programs and Tutorials

Getting into digital learning: The many e-learning programs and tutorials provide support with the professional execution of service activities in final assembly or help with the guided step-by-step solution of complex plant-related issues.

Digital learning contents in Full HD

- Filling Adapter Repair bundle: Tutorials for maintaining all generations of Somac® filling adapters, with detailed step-by-step assembly guidance from three camera angles

- Preventive Maintenance bundle: Tutorials for preventive maintenance tasks on Somac® filling equipment

- Calibration bundle: Tutorials for calibrating sensors on Somac® filling equipment

Functions

- Recommendations how to solve equipment failures

- Target group specific, visual educational trails and practical video sequences

- Current und standardized learning program

Benefits

- Step-by-step guidance for calibration and repair

- Access to learning content independent of time and location and individual learning curve

- Access to the interface on any authorized mobile device