Cyplan® ORC

Cyplan® ORC by Dürr offers the world’s most flexible ORC platform and can integrate a wide range of heat transfer media into its ORC systems. We provide complete solutions with customized service, ensuring that the systems are fully optimized and individually integrated into your existing processes—without interfering with the primary process. This allows additional electricity and useful heat to be generated locally, enabling environmentally friendly cost savings.

Advantages of the Organic Rankine Cycle (ORC)

- CO2-free power generation

- Attractive heat utilization concepts with high returns

- Enabler for subsidies and/or tax reductions

- Lower energy costs through self-generation

- Increased efficiency with short payback periods

- High electrical efficiency

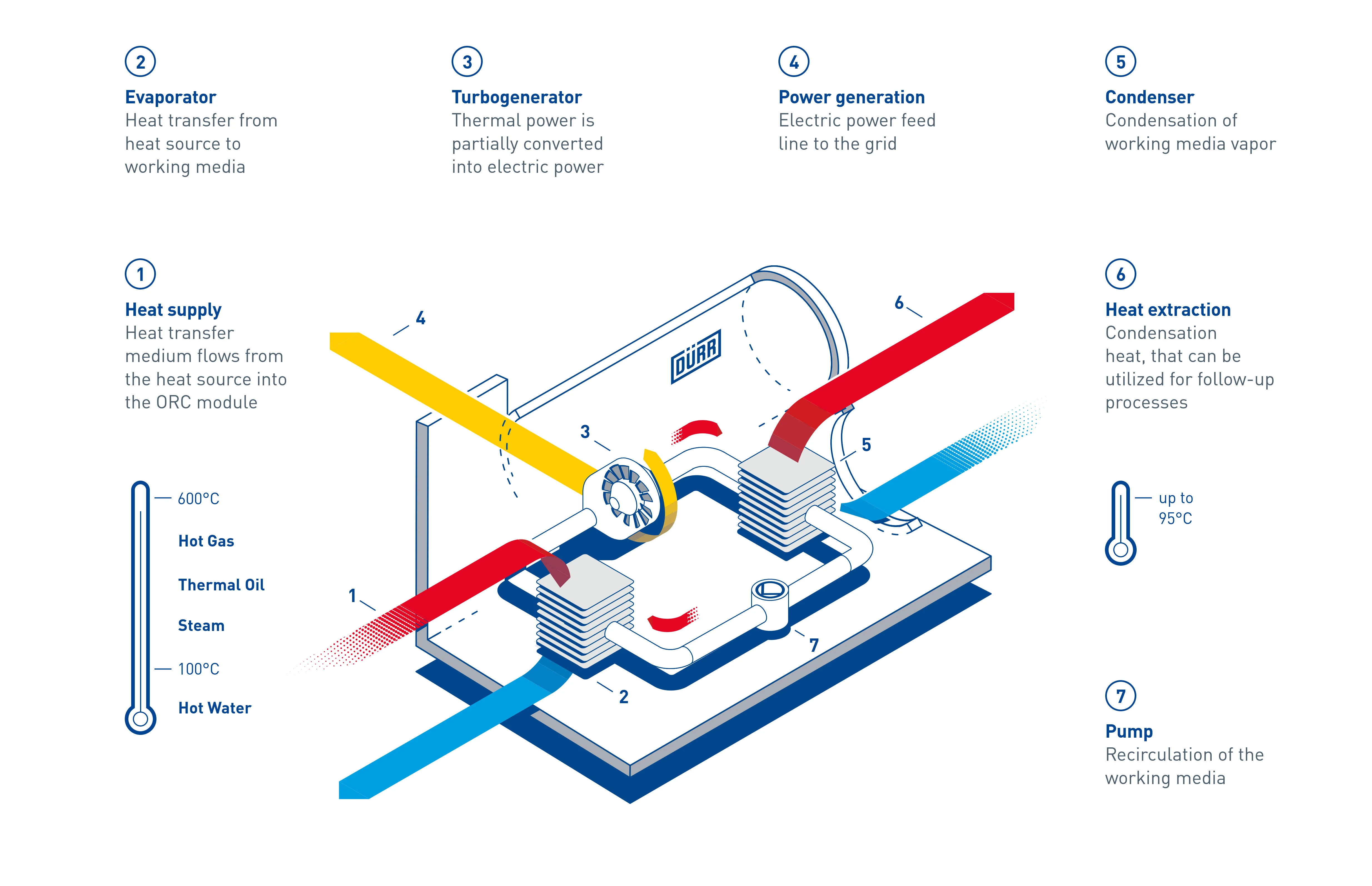

Operating principle Organic Rankine Cycle (ORC)

The ORC process is a thermodynamic cycle similar to the well-known water-steam cycle used in conventional power plants for electricity generation. The main difference is that the ORC cycle uses an organic fluid with a low boiling point. This enables ORC systems to operate efficiently at lower temperatures than conventional steam cycles.

Heat Transfer Media

The Cyplan® ORC platform is one of the most versatile solutions on the market worldwide and is distinguished by its exceptional adaptability to a wide range of requirements. The technology can be used economically even at a low power output of around 500 kWh.

A particular advantage of Dürr’s Cyplan® ORC technology is the wide selection of compatible heat transfer media. Our systems are designed to efficiently utilize a variety of media, such as hot water, molten salt, steam, hot air, exhaust gases or thermal oil.

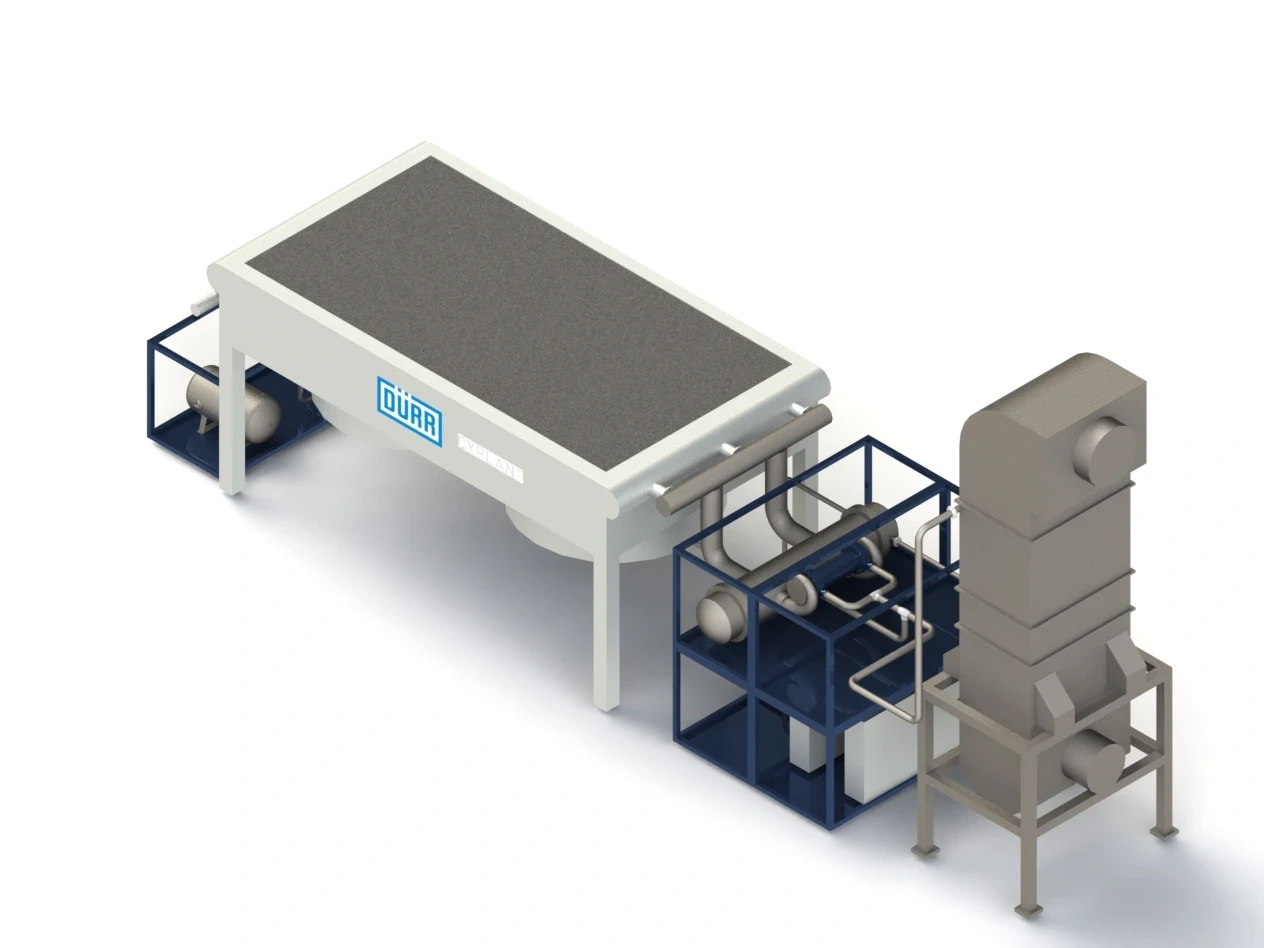

Incinerations

A Cyplan® ORC module added to a furnace can be combined with any kind of incineration: wood-based fuel, waste from wood processing, sewage sludge, small-scale municipal waste, etc. Cyplan® ORC can also be integrated with innovative thermal processes such as pyrolysis and biochar.

- Energetic utilization of existing organic residues

- Suitable for all kinds of furnaces

- Secondary heat use downstream of ORC

Industrial waste heat

Dürr can upcycle all kinds of heat above 90°C and transform it into electricity independent of the heat carrier (water, steam, thermal oil, hot gas). Typical industries are glass, cement and steel.

- No intrusion into production process

- Reduces carbon footprint

- No operator needed

Engines/ CHP Units

The Cyplan® ORC can be combined with all types of stationary gas and diesel engines such as biogas, sewage gas and landfill gas and has the potential to increase electrical output by up to 10%. Due to the direct evaporation technology the module is installed in the exhaust gas path between the engine and the stack.

- CHP capability

- Saves 3–5% of input fuel

- Electricity-producing heat exchanger with more than 95% heat usage

Geothermal energy

Dürr Cyplan® ORC plants can be utilized as modularized power plants, wellhead generators, upgrades for existing flash plants with an additional binary cycle or seasonal operation plants.

- Modular and flexible design

- Operation optimized through cascade alignment

- Suitable for operation in adverse outdoor environments

Biochar

Pyrolysis plants that utilize biomass as a feedstock aim to produce biochar and generate negative CO2 emission credits. A secondary effect of these plants is the production of excess heat due to the exothermic nature of the process. Integrating a high-temperature ORC system into a pyrolysis plant notably enhances the overall efficiency of the process.

- Provision of usable heat

- Generation of CO2-free electricity

- Credit for CO2 sink certificates possible

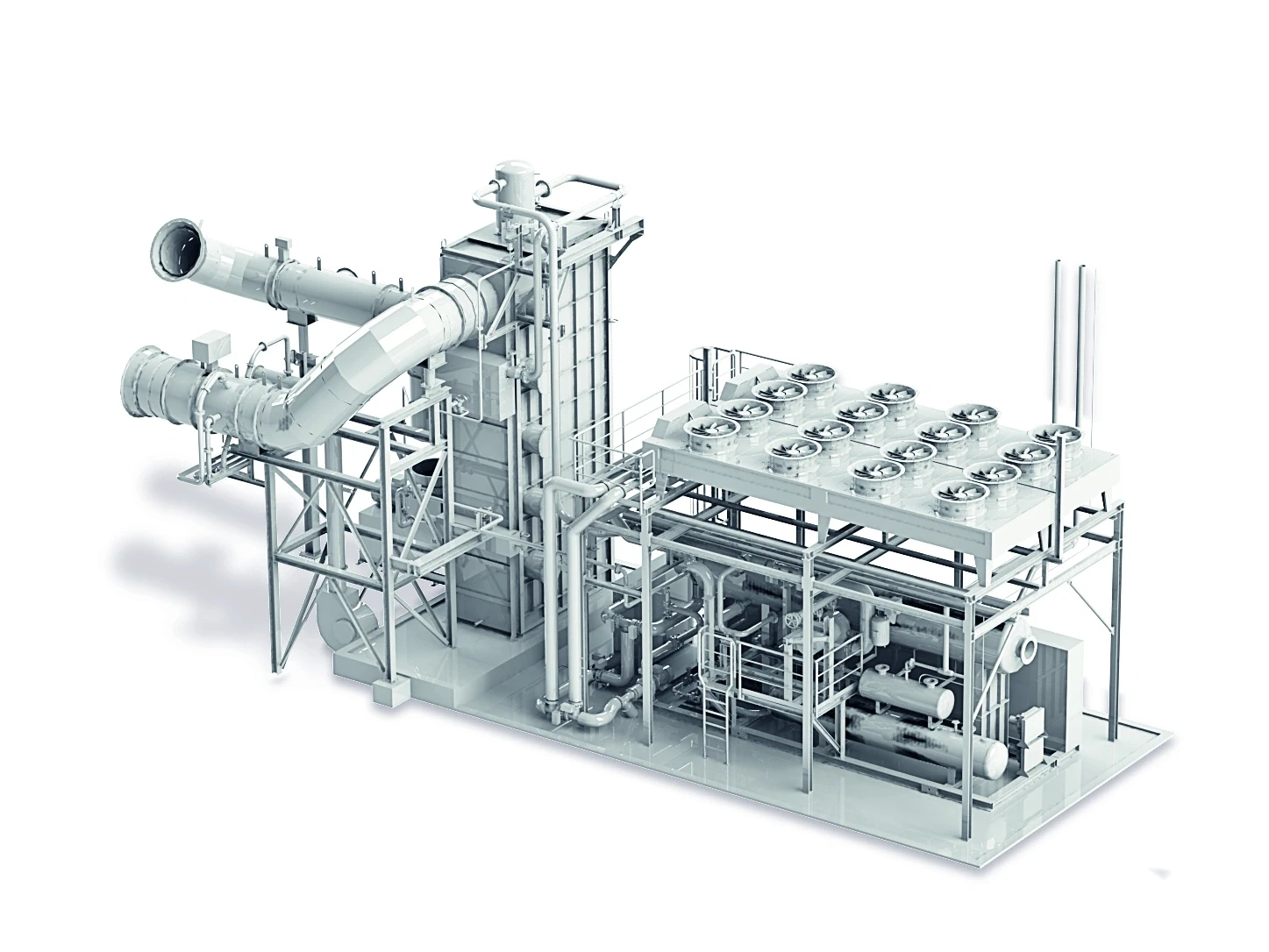

Gas turbines

Cyplan® ORC modules are an ideal add-on for small to medium-sized gas turbines running in open cycle. The potential output increase without additional fuel input is up to 25%.

- Fuel flexibility

- Direct evaporation

- Functions without water

Solar thermal energy

Cyplan® ORC can be applied to different types of solar energy plants as a high-temperature solution in combination with a secondary heat source or as a low-temperature solution after the thermal storage.

- Excellent part-load behavior

- No water consumption

- Key element for hybrid power plants

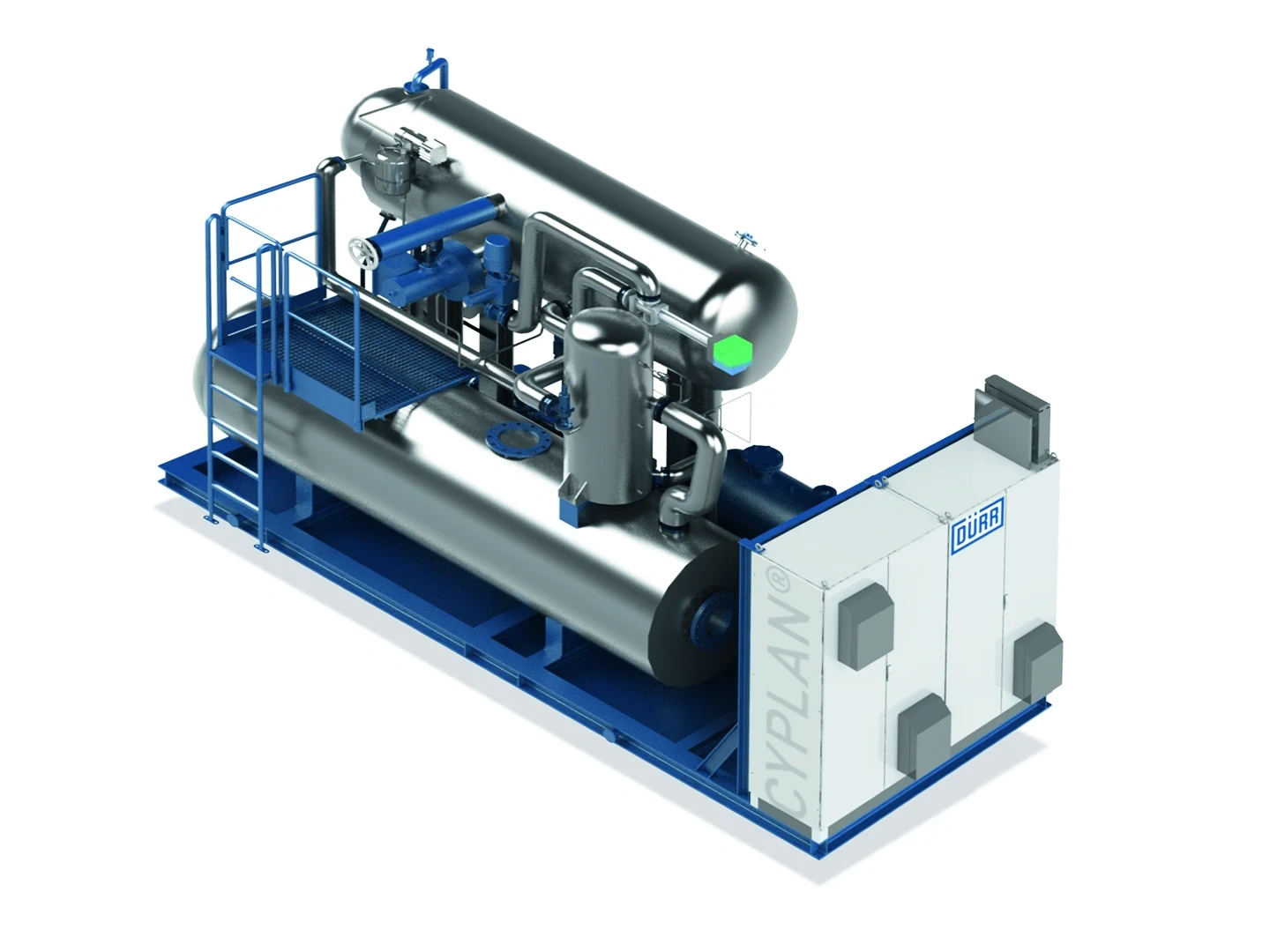

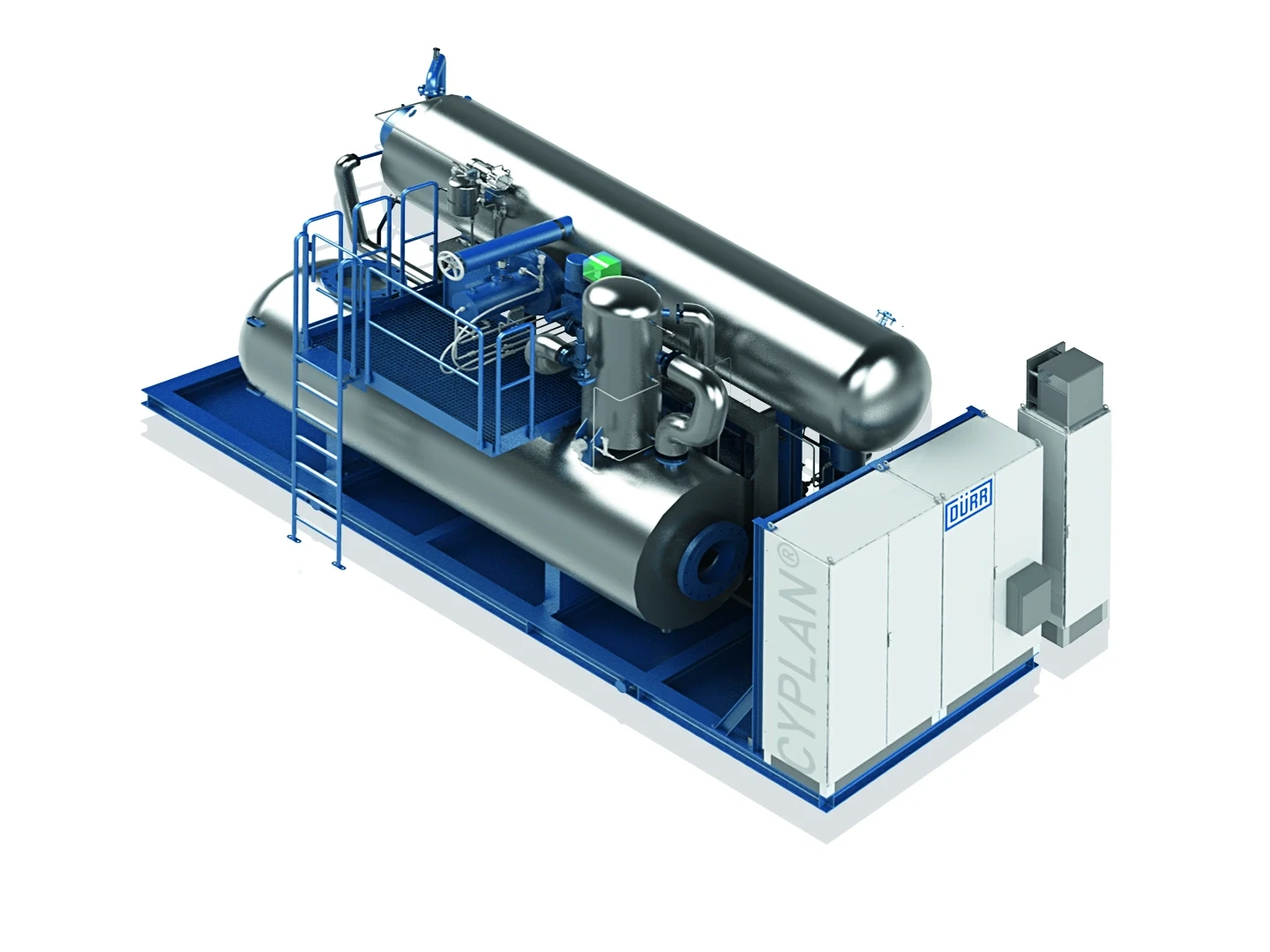

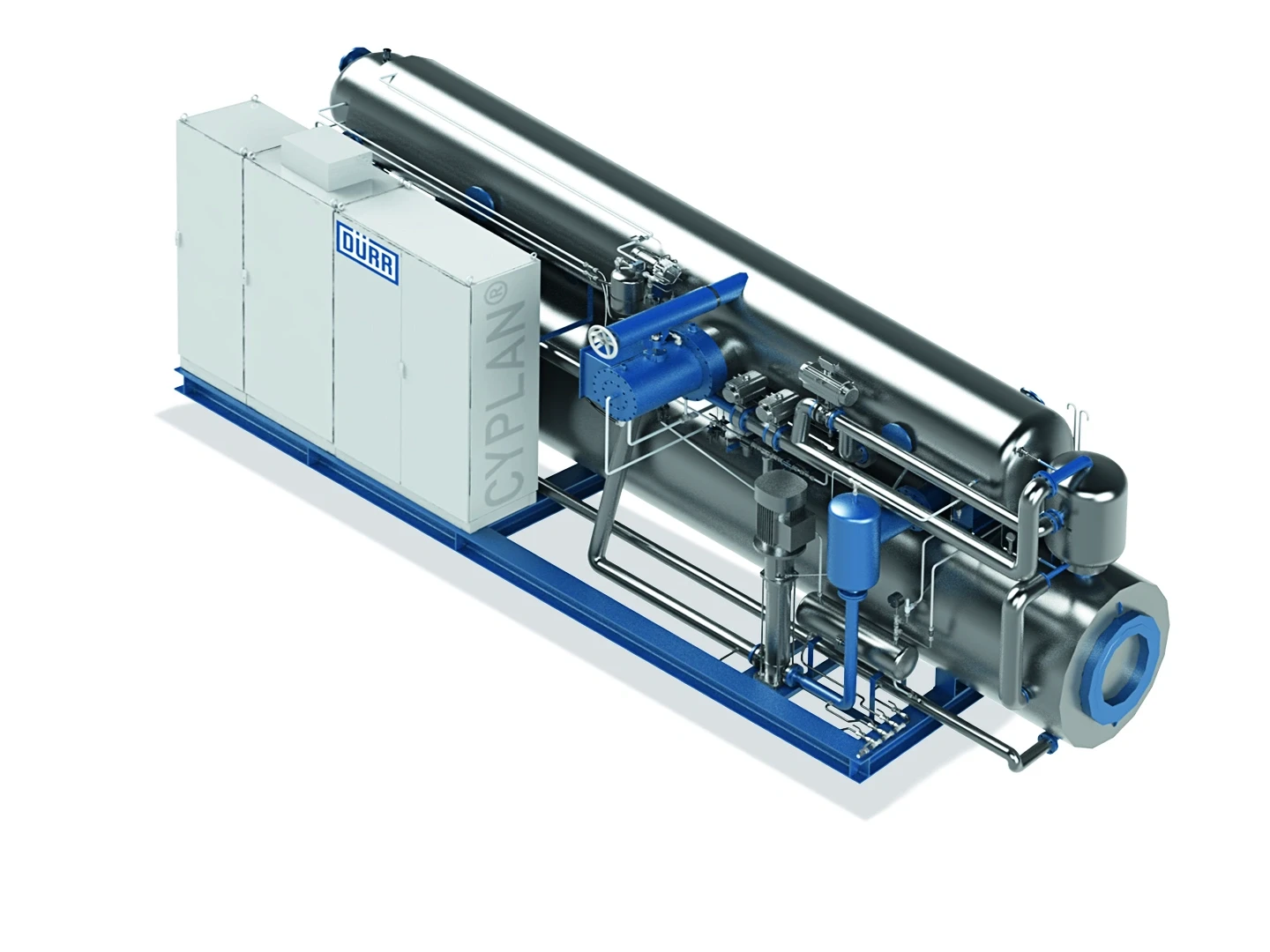

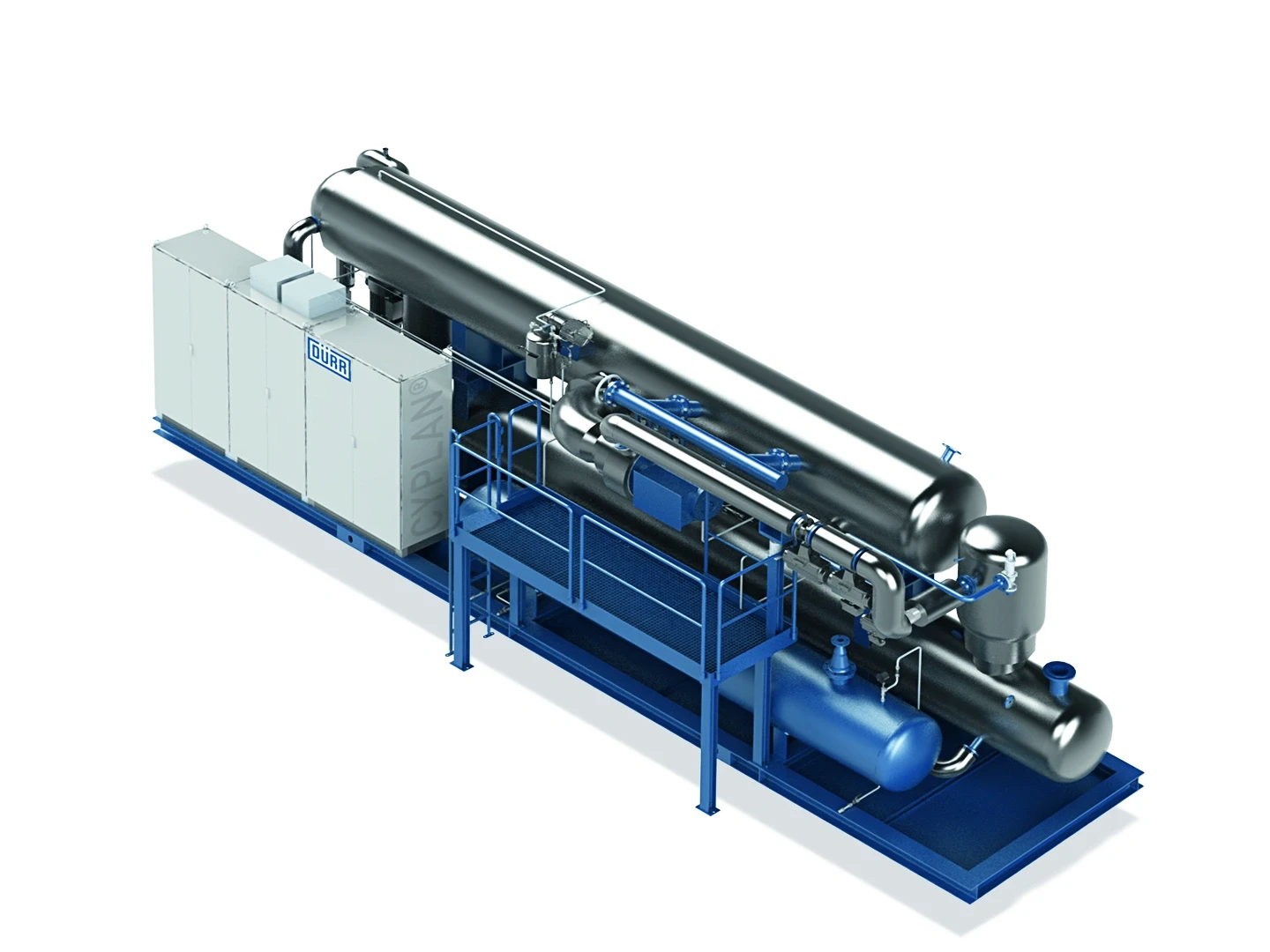

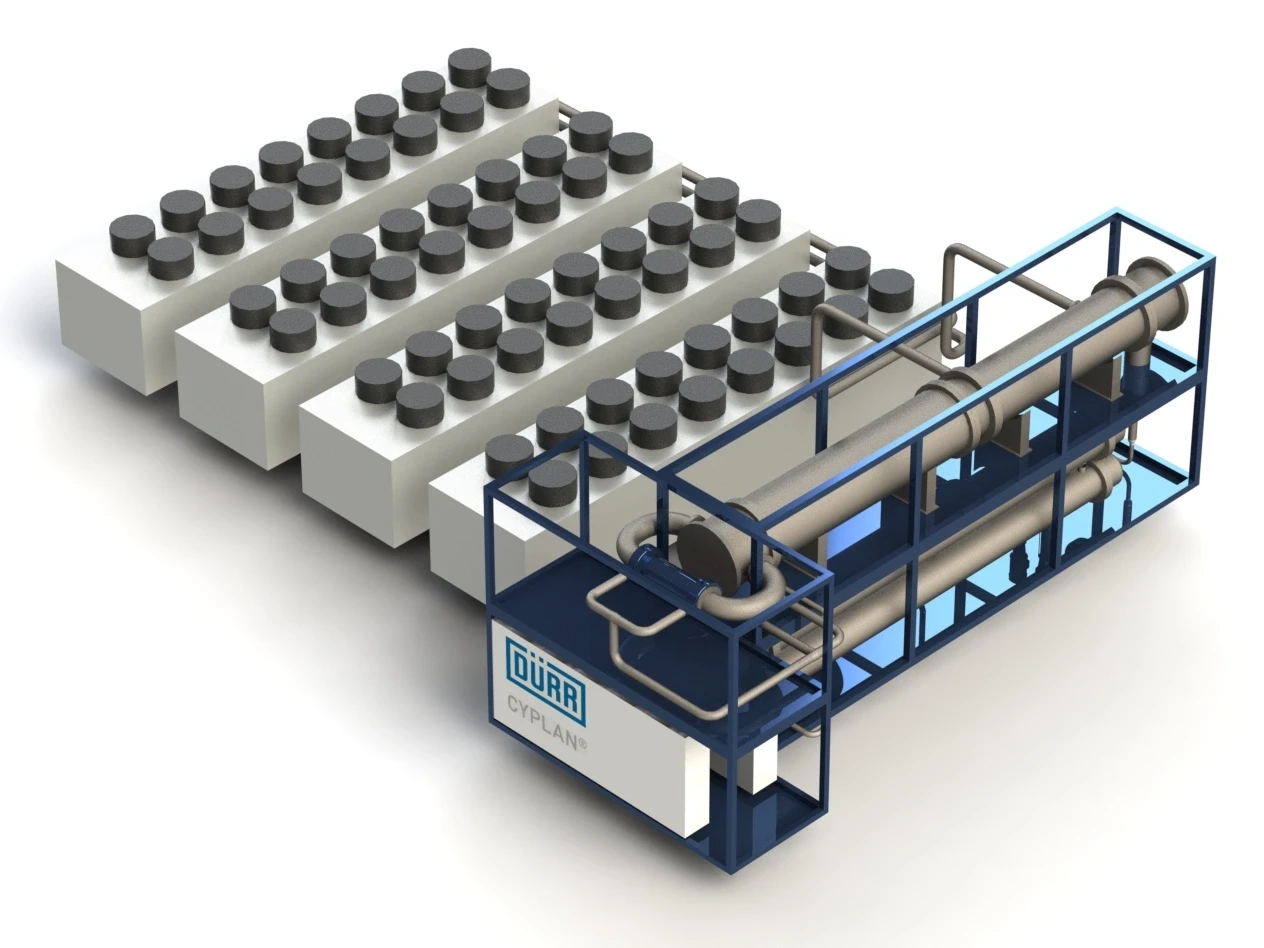

Dürr offers Cyplan® ORC modules as prefabricated and TÜV-certified units, starting from 50 kW of electrical output. The power output corresponds to the size of the turbo generator.

Our standard ORC-modules:

For larger plants or industrial applications, Dürr develops customized ORC solutions by combining standard modules with components tailored to specific requirements. Dürr Cyplan® ORC modules are delivered fully pre-assembled and pre-tested to ensure easy and rapid installation and commissioning on site. The robust industrial design guarantees maximum reliability and minimal maintenance.

Customized Solutions

Our customized solutions can be flexibly adapted to our customers’ specific requirements, both in terms of electrical output and type of cooling.

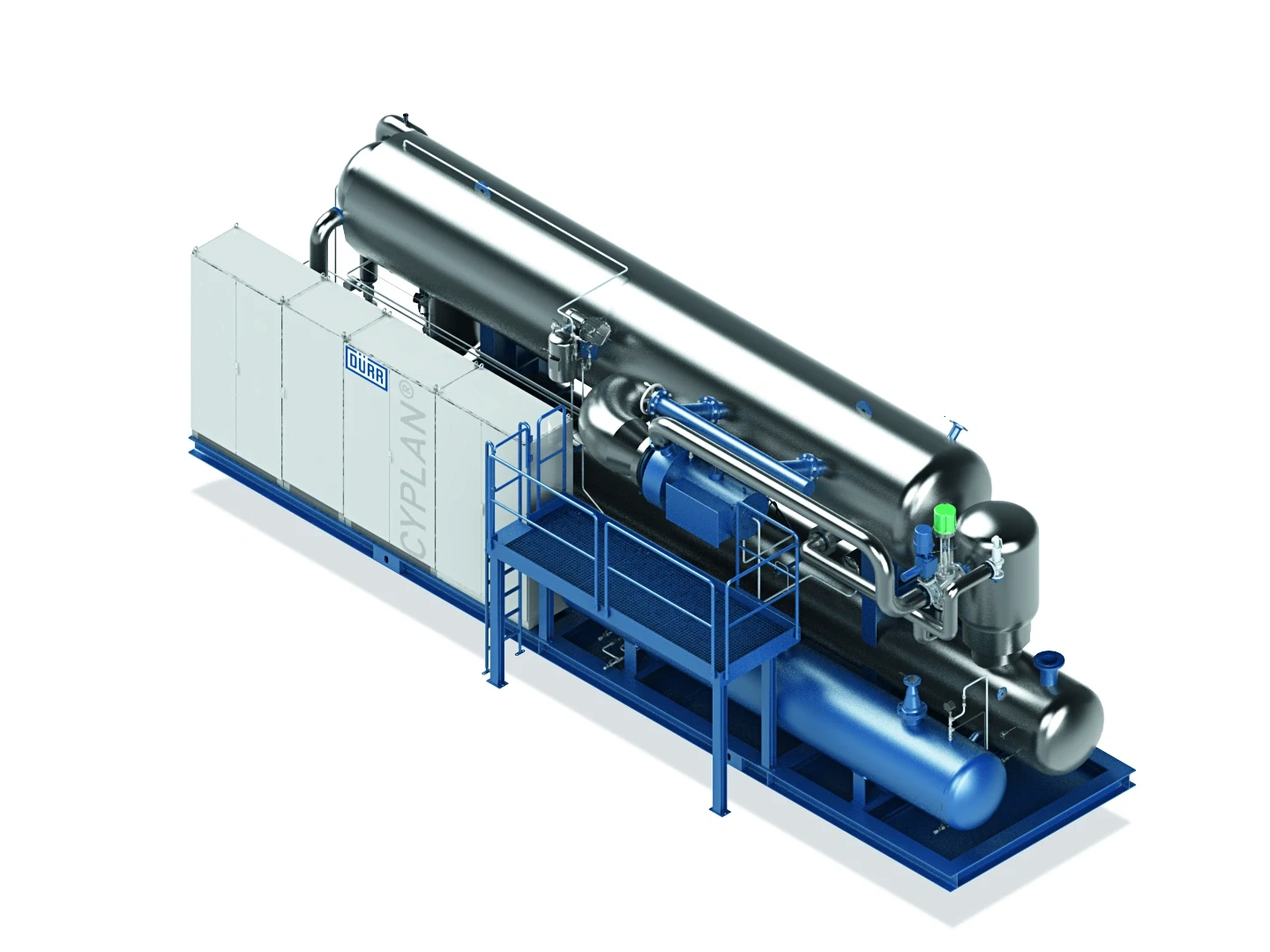

The Cyplan® ORC module is one of the most flexible and efficient converters of heat into electricity, even at low power levels. Our systems stand out due to the following unique features:

The hermetically sealed working fluid circuit ensures that no fluid escapes, protecting the environment and allowing uninterrupted operation.

The compact expansion turbine of the Cyplan® ORC is single-stage and robustly built. Thanks to its highly efficient design, electricity can still be generated even at 20% partial load.

In highly efficient combined heat and power (CHP) operation, the ORC system generates not only electricity but also heat, resulting in an overall efficiency (conversion of available waste heat into electricity and usable heat) of over 95%. This secondary heat extraction is possible at temperatures up to 95°C in high-temperature processes and is particularly beneficial when heat is required for purposes such as heating or drying. The primary process remains unaffected.

Depending on the application and industry, a wide range of heat transfer media can be used. With our Cyplan® ORC systems, flue gas, thermal oil, molten salt, saturated steam or hot water can be utilized.

Operation of our ORC systems is reliable and associated with only minimal operating costs. Since a wide range of spare parts is always available and critical wear parts are easily accessible, all inspection and maintenance costs remain low.

Additionally, our systems can be remotely monitored if required, providing valuable information about current operating conditions, performance and faults. This ensures optimal maintenance and operating status at all times.

Dürr’s customer service provides expert support anywhere in the world. We are always on site to help reduce your production costs and increase your plant availability, ensuring fast technical support whenever needed.

We offer a comprehensive service package that can be tailored to your individual requirements. Our services include prompt repairs, preventive maintenance, consulting and upgrades for your system.

Our customers not only receive reliable products for clean electricity generation, but also comprehensive support throughout every project phase. From turnkey projects and expert project management to staff training, Dürr offers the right solution. Our experienced project management teams guarantee transparency and seamless communication, ensuring completion of the agreed scope within defined time frames and budget.

We don’t just deliver a system – we deliver a complete solution package.

Our service at your demand

- Ramp-up and launch management

- Modifications and upgrades

- Engineering with experience

- Spare parts service

- Expert engineering

- Inspection and maintenance

- Service locations all over the world

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany

1925 Highway 51 - 138

53589 Stoughton, WI

United States