Our portfolio for the carbon fiber industry

The carbon fiber industry works with industrially produced fibers from carbonaceous feedstock. These fibers are converted by chemical reactions that have been specially adapted to the raw material. The processes for composites and carbon fiber require multiple solutions at every stage of production, from manufacturing through to recycling. Dürr offers air pollution control systems, as well as customized process drying and curing equipment.

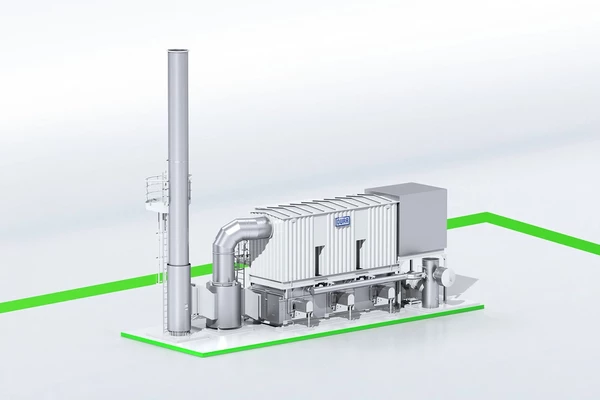

Exhaust Gas and Air Pollution Control

When a process requires environmental control systems for solvent-based applications, Dürr supplies regenerative thermal oxidizers, solvent recovery solutions, wet scrubbers, and distillation and purification systems. In addition, our waste-heat recovery systems can “close the energy loop” between pollution controls and the process in order to reduce production costs.

Dürr offers customized exhaust gas treatment systems for composites and carbon fiber production. The Oxi.X regenerative thermal oxidizers (RTOs) deliver high-efficiency VOC destruction over a range of flow metrics. With VOC destruction typically at 98% to 99+%, and thermal efficiency up to 97%, the Oxi.X RTOs provide exceptional operating economy.

Thermal oxidation is the most effective and efficient method of controlling hydrogen cyanide (HCN), ammonia (NH3), carbon monoxide (CO), tar, and other VOCs and HAPs discharged from the fiber oxidation ovens and carbonization furnaces used in the processing. These emissions present a danger to human health if not properly treated, and thermal oxidation is the most effective and efficient method of managing them.

We also understand the need to produce carbon fiber competitively, so we utilize proprietary solutions to reclaim heat, which effectively lowers the production cost per ton of carbon fiber produced.

Preventive Maintenance Services

There is a definite link between the productivity, reliability, and maintenance of environmental equipment. The primary benefits include reduced operating costs, consistent product quality, and an increased lifespan for valuable capital equipment. Maintenance also preserves capital assets and fulfills safety, insurance, and regulatory obligations.

The Dürr Preventive Maintenance Services staff can help maintain your equipment. Our team of factory-trained technicians have an average of 20+ years of experience and can evaluate what your equipment needs to keep it functioning at its optimum level.

Drying and Curing

Dürr provides roll-to-roll drying, curing, and thermal air-handling systems for coating and laminating applications, such as carbon fiber, composites, and thermoplastics, regardless of whether you need a small, value-priced roll-support dryer, a custom-configured air flotation dryer, or a complete coating line for a specific application. Our technical application and design engineers work with process specialists and OEM suppliers to develop systems that provide reliable, high-production performance for composite and carbon fiber web handling, drying and curing carbon fiber, and roll-to-roll thermal air handling.

Dryers can be equipped with different nozzle configurations ranging from simple slot nozzles to sophisticated Coanda-style air bars and patented airfoil systems. Multiple heat sources are available, including steam, direct and indirect gas-firing, thermal oil, electricity, hot water, and IR. In addition, the air-handling systems can be integrated into the dryer enclosure or used as stand-alone solutions for remote installation.

Our custom and hybrid dryer models and designs, together with our configurations for clean-room applications, include:

- Convection air/non-contact flotation

- Combination of convection/IR

- Catenary convection air

- Roll support

- Festoon

- UV

- Tentering

- Can/drum

- Through-air

- Inert