Ralf W. Dieter, CEO of Dürr AG, says: “As a world market leader, not just in paint systems, we know the processes in automotive production inside out, and we know what is important. We combine this expertise with our software skills to develop applications for optimizing production processes. Our customers will see the results at the Open House.”

At Dürr’s Digital Factory, a cross-departmental software competence center, around 100 experts work on innovative applications. Among them is the digital maintenance assistant, DXQequipment.maintenance. It shows maintenance dates for components in automotive paint shops, for instance for robots, pumps or valves. In addition, it provides access to instructions and creates a maintenance history. Another example to be showcased at the Open House is the analytics software, DXQequipment.analytics. It records all data from the painting process, creating a ‘digital fingerprint’ for each painted car body. It contains information, for example, on the robots’ movements, on paint consumption, and on the exact position of the car body during painting. In the event of a quality problem, the cause can be determined immediately using the recorded data.

Customized paint application without overspray

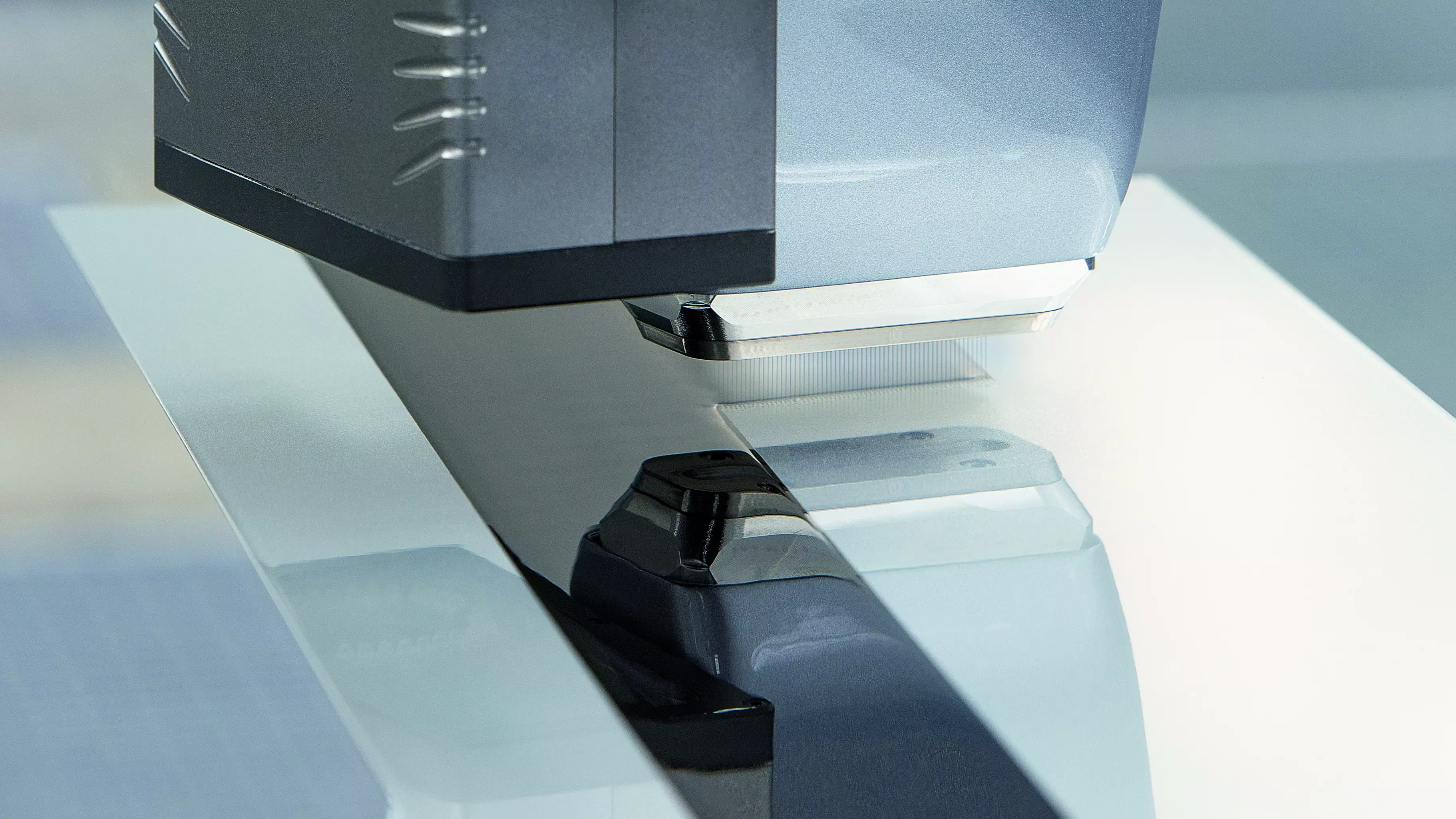

The trend for car colors is toward customization. Dürr has developed the pioneering EcoPaintJet process for the two-tone painting of car bodies. Aside from saving carmakers time and energy, it also generates less waste. In this overspray-free painting process, a robot applies the contrasting or accent color so accurately that no overspray is produced. This dispenses with the need for masking the other areas of the car body. EcoPaintJet also offers benefits in the painting of electric vehicles. These often have a higher structure to accommodate the battery in the vehicle floor. Two-tone painting makes them look flatter. Aside from overspray-free painting, Dürr’s Open House will also feature other automation solutions for paint application, sealing and cleaning of car bodies.

Talking about the importance of overspray-free painting, Dr. Jochen Weyrauch, CEO of Dürr Systems AG, says: “Applying sharp lines of paint enables us to forge new paths in paint application and offer carmakers significant productivity benefits. This process sets us apart from our competitors.”

Automated guided vehicles

In automotive factories of the future, automated guided vehicles (AGVs) take car bodies and materials to their relevant processing stations. AGVs are more versatile than conventional conveyor technology lines. As a result, they enable factories to have a more compact design. Dürr’s new EcoProFleet automated guided vehicle, which will premiere at the Open House, is equipped with smart sensors and used in paint shops. Dürr has recently received a design award for this innovative conveyor system.

Another topic at the innovation show will be the purification of polluted exhaust air, generated in industrial production processes. Thanks to the latest generation of Dürr’s environmental technology systems, it is now possible not only to comply with but even to stay below the increasingly stringent emission limits.