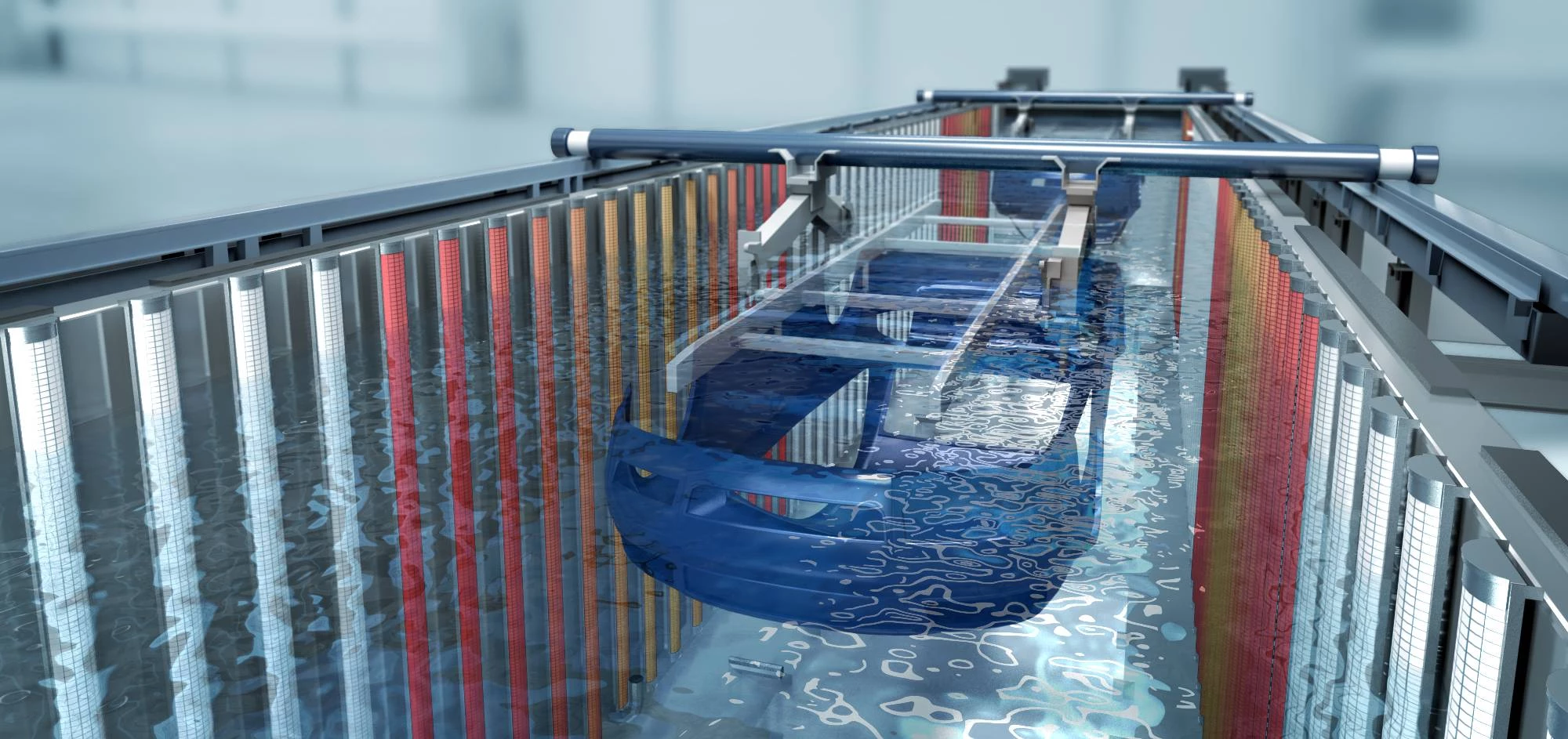

As the car body makes a full 360° rotation in the tank, RoDip requires no entry and exit ramps. This significantly reduces the length of the dip tank. The reduced tank volume not only ensures a smaller footprint but also a lower material and energy consumption. At the same time, RoDip provides for uniform coating thicknesses, also at critical points such as the rocker panels. The optimized process of immersion, flooding and draining ensures optimum corrosion protection.

Ecopaint RoDip E – with the new control, now also suitable for commercial vehicles

The rotating dip process of Ecopaint RoDip E is operated with an electrically driven trolley unit on one side of the tank. In addition to continuous operation, it can be run in stop-and-go operation; programming of individual dip curves is possible as well.

Based on the development of a new heavy-duty carrier, Ecopaint RoDip E is also suitable for coating commercial vehicles. This carrier unit transports commercial vehicles and minivans through the pretreatment and dip painting stages.

A new control that is compatible with all leading PLCs has been developed for Ecopaint RoDip E. Safe operation without any disturbances is achieved by means of a 5-GHz frequency band for data communication. An optimized Job Manager, software specifically developed for programming body-specific process sequences, allows up to 20 different dip curves and high production capabilities.

EcoDC MACS - the failure-proof ED solution

In conventional ED baths, electricity is supplied in sections to the entire dip tank. With EcoDC MACS, Dürr has developed a new concept for the targeted supply of electricity and voltage to dip tanks, which has a positive effect on energy consumption as well as on the coating quality of the car bodies. The special feature of the EcoDC MACS lies in its modular anode control, which creates a voltage profile that moves with the car body. This is enabled by the fact that the anodes can be individually activated and deactivated. The benefit is obvious: In the event of a failure of one of the modules or anodes, the neighboring anodes can take over their task. This ensures that there is no loss of production if individual anodes fail.

EcoMulticyclone – Nano Removal of solid particles of 10µm and up

Dürr has developed another variant of its well-proven EcoMultiCyclone Micro. Both EcoMulticyclone Micro and EcoMultiCyclone Nano are used for cleaning the pre-treatment baths in automotive painting, significantly contributing to a high coating quality and thus to a perfect surface finish.

In combination, they are particularly powerful: In the first degreasing zones downstream of the body shop, the EcoMultiCyclone Micro filters out coarse particles. With particles of a diameter of 50µm, a 100% separation efficiency is achieved, and 90% with a particle size of 30µm. The EcoMultiCyclone Micro is highly resistant to blockage. Latest in degreasing zone III, the EcoMultiCyclone Nano removes particles smaller than that, achieving a 90% separation efficiency with 10µm and 100% with 20µm particles.

Thanks to their ease of maintenance and the break-proof cyclone inserts, the combination of EcoMultiCyclone Micro and Nano is a guarantee for premium-quality coatings. After all, PT and ED account for 50% of the quality of the finish.