Regenerative Thermal Oxidation (RTO) is a highly effective technology for the cleaning of exhaust air laden with hydrocarbons or odors that has proven successful in many areas of industry.

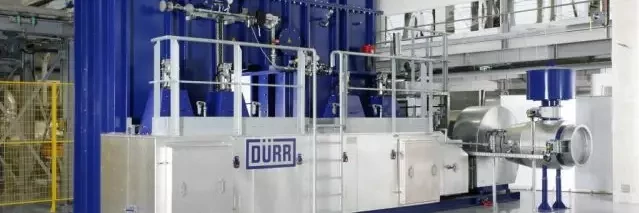

As a further development of its own line of RTO systems, Dürr has successfully engineered the compact Ecopure CTO regenerative thermal oxidizer series for process exhaust air flows of between 5,000 and 20,000 Nm³/h.

The Ecopure CTO regenerative thermal oxidizer comes in two standard engineered models. The first, a two chamber design, achieves up to 98% destruction efficiencies while remaining supremely cost efficient. Additionally, a three chamber design is available to attain the highest of destruction efficiency requirements, greater than 99%. Further, various options are available that enable the CTO system to be ideally adapted to even the most unique processes and stringent compliance requirements.

The Ecopure CTO regenerative thermal oxidizer is skid mounted and completely assembled mechanically and electrically in any one of Dürr’s fabrication facilities. This ensures direct oversight of all systems, guaranteeing a high level of manufacturing quality and workmanship. The engineering standardization of components and pre-assembly of the CTO before arriving at a customer’s facility throughout both models allows Dürr to present an extraordinarily efficacious system at a low capital investment cost coupled with low operating costs.

The compact design of the CTO, with special attention paid to height, , makes it especially suitable for use indoors along with typical outdoor areas. The CTO is delivered “ready to connect.” This means when the CTO arrives on-site, no further mechanical or electrical installation work is required. The system can be set up within half a day with only process exhaust air and utility connections needing to be connected before commissioning.

During initial development, engineering, and standardization of the CTO regenerative thermal oxidizer system, Dürr paid particular attention to the use of high-quality equipment components. Furthermore, Dürr kept the customer’s operators and staff in mind while designing unique functions and features to allow for more efficient and reduced cost maintenance.

Application example: A&R Carton

A&R Carton GmbH relies on CTO regenerative thermal oxidizer technology from Dürr at their facility in Königsbrunn. Process exhaust air from a new deep-draw machine used for the printing of cigarette packs has been abated with a Dürr CTO for over a year now with three-shifts operating consistently.

The energy content of the solvents contained in their process exhaust air allows the system to run autothermally in normal operation meaning no additional natural gas needs to be consumed. Destruction efficiency compliance testing carried out by local authorities has thoroughly impressed everyone at A&R Carton GmbH.: “The emission values in the stack are almost better than the values in the surrounding atmosphere,” remarked the environmental protection officer at A&R Carton GmbH.

In addition to its success in abating process emissions from the printing industry, the CTO regenerative thermal oxidizer system from Dürr is used by well-known automobile manufacturers to remove solvents from process exhaust air produced by their painting lines. CTO technology is also used in the painting of automotive components made from plastic as well as in the manufacturing of paint. Other industries with low process exhaust air flows that can benefit from the use of a Dürr CTO include the coating industry and the chemical industry with its unique and specialized processes.

With the CTO series, Dürr has enhanced its product portfolio for regenerative oxidation systems with a unit that offers an economical and versatile system for small process exhaust air flows.