EcoPaintJet Pro / EcoNextJet – Overspray-free paint application

The more individual, the better, and colors are no exception. Contrasting colors on roof surfaces or A- and C-pillars, striped designs, and even high-resolution graphics are currently in vogue: The demands on design and technology for overspray-free contrasting paint finishes are high. The systems should apply the paints flexibly with different colors and paint types to various surfaces, including vertical ones, without hindering the manufacturing process—and at the lowest possible production and environmental costs.

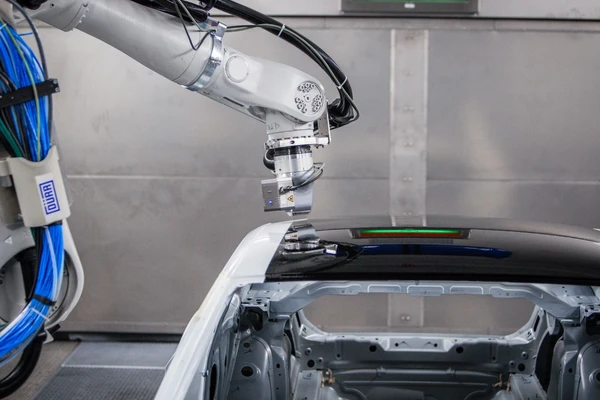

Dürr has developed two systems for this demanding task: With the EcoPaintJet Pro, we can apply two-tone paint finishes and simple design elements efficiently and sustainably, e.g., on roofs, A- and C-pillars, or decorative strips. There is no overspray and no waste from masking.