Interstuhl Büromöbel GmbH & Co. KG, headquartered in Meßstetten, is one of Europe's leading chair manufacturers, producing high-quality office chairs for over 60 years. The company now employs innovative coating technology from Dürr in the production of its industrial and laboratory chairs. The EcoGun AS AUTO pro spray gun precisely coats the inside of the foam mold. As soon as the liquid PU foam is poured into the mold, it absorbs the coating and assumes its color.

“The paint used is special—it serves multiple functions,” explains Fabian Schilt, Head of the European Industrial Sales Team at Dürr. “In addition to providing color, it provides the necessary conductivity. Since the chairs are used in cleanrooms and ESD areas, among other environments, it is essential that no static charge is generated.”

Compact paint supply with EcoSupply2 Core

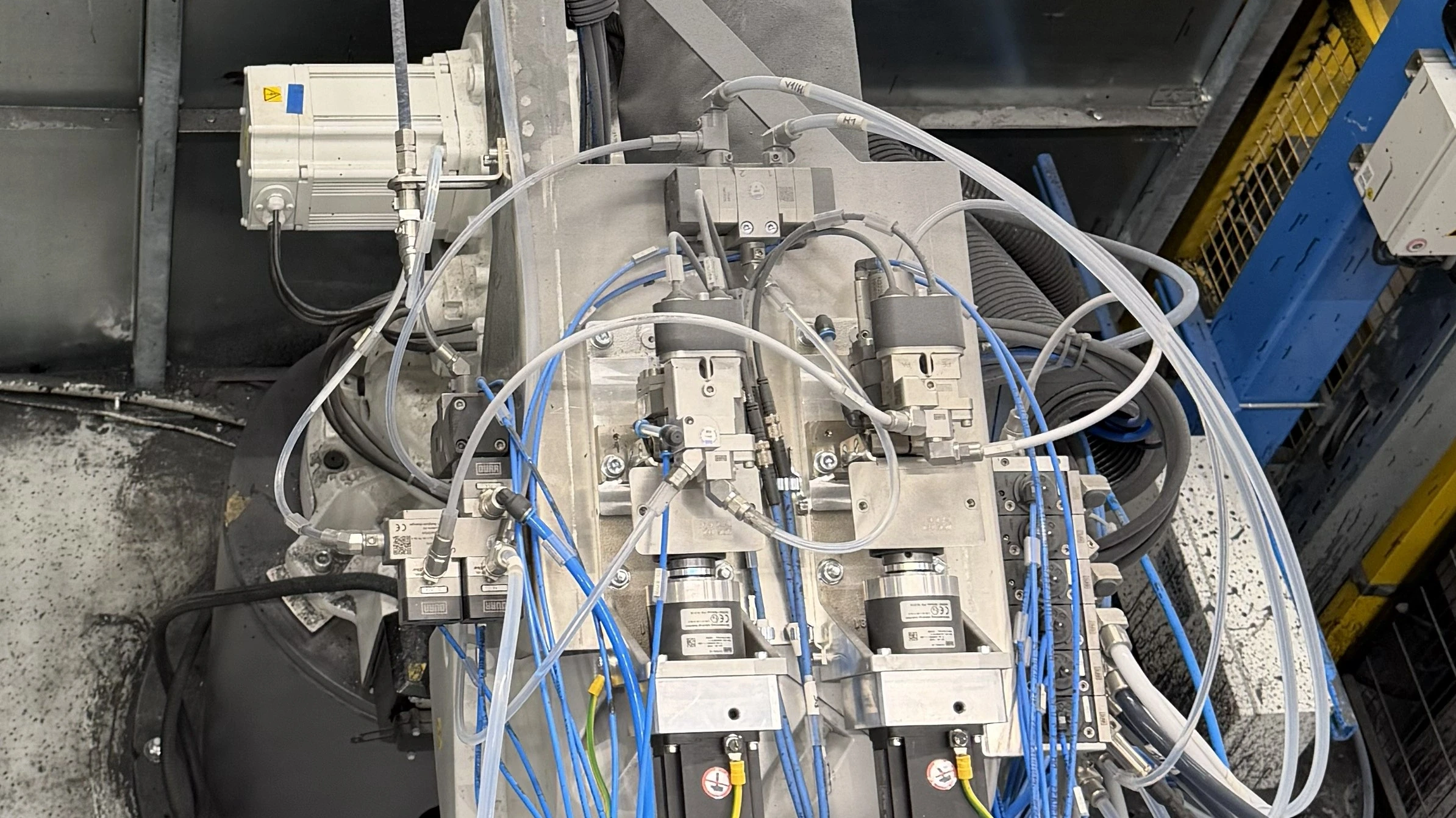

In September 2025, Dürr supported PU plant specialist Hennecke with the installation of painting equipment on an existing robot at the Interstuhl site in Meßstetten-Tieringen. The system includes a painting robot equipped with the EcoGun AS AUTO pro spray gun, six EcoSupply2 Core stations for paint supply, and the EcoAUC 2K control unit. Interstuhl currently processes three colors, but the system is already designed to handle up to five colors.

The EcoSupply2 Core paint supply station is space-saving and user-friendly. It is ideal for industrial applications where painting occurs in confined spaces. At Interstuhl, the systems are additionally equipped with pumps from the EcoPump9 series, valves, and paint change blocks—components that have particularly impressed the company. This is due to the paint material used has special requirements: it is difficult to flush, hardens quickly, and tends to clog valves.

Ready for practical use

Extensive testing at the Dürr Test Center in Ledeč nad Sázavou, Czech Republic, proved that Dürr valves have no dead space – no material settles, ensuring reliable and clean processing. “We were convinced by Dürr right from the first demonstrations of the painting technology,” says Andreas Kunst from Interstuhl. “The technical team was always there to support us and led the project to success with a great deal of expertise and commitment.”