Notizie

Qui sono riportate tutte le informazioni sui progetti aggiornati, nuovi prodotti, eventi e altri comunicati stampa di Dürr. Se avete domande sulle pubblicazioni o avete bisogno di ulteriori informazioni potete contattarci.

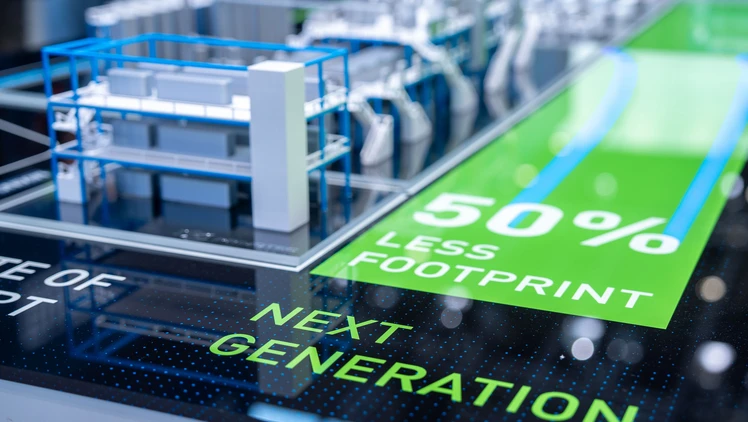

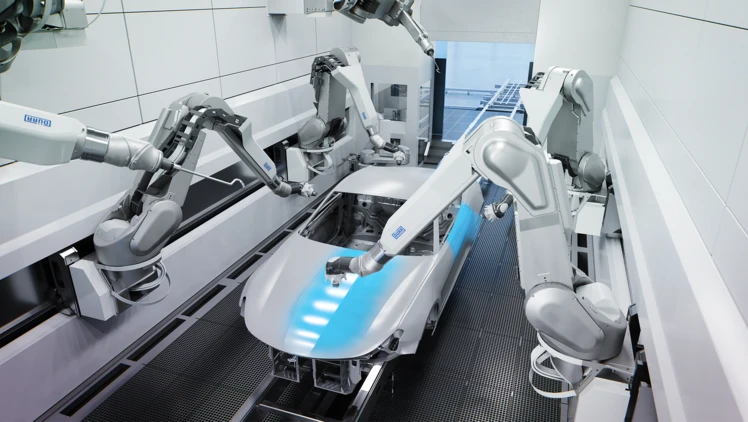

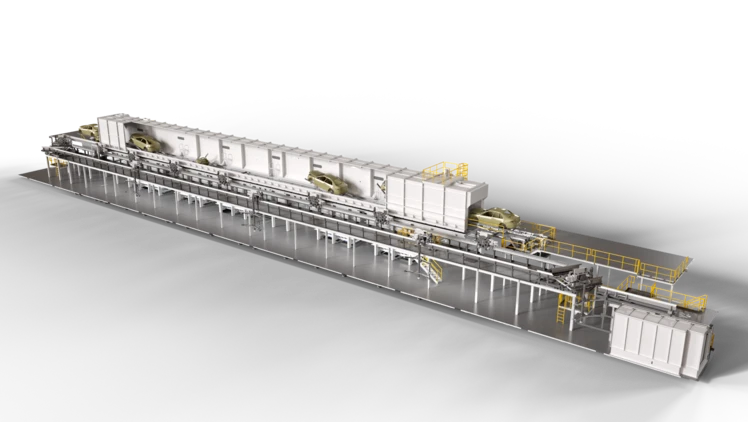

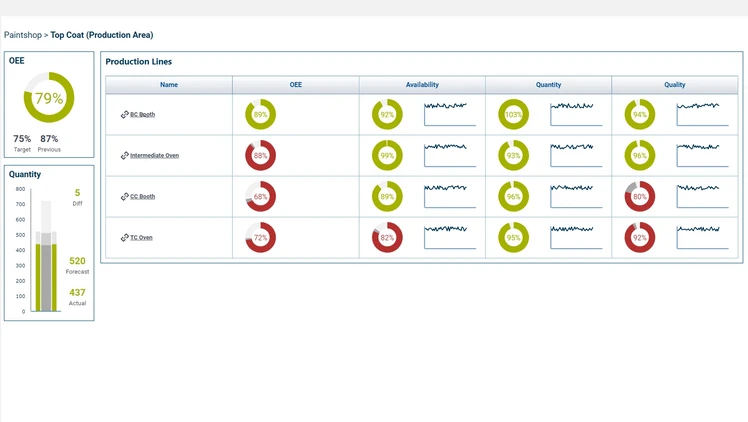

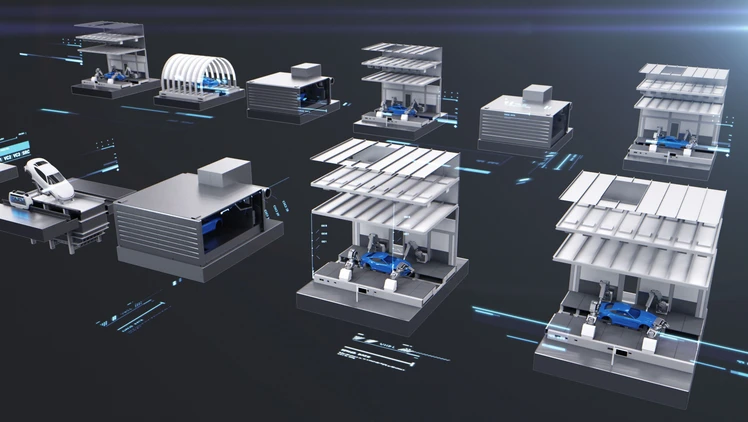

Il gruppo Dürr è una delle aziende leader a livello mondiale nell’ingegneria meccanica ed impiantistica con particolare e comprovata competenza nei settori tecnologici dell’automazione industriale, della digitalizzazione / Industria 4.0 e dell’efficienza energetica. I suoi prodotti, sistemi e servizi consentono processi di produzione altamente efficienti e sostenibili principalmente nell'industria automobilistica, nell’industria di produzione e lavorazione di mobili e case in legno, ma anche in settori come l'industria chimica, farmaceutica, dei dispositivi medici, ingegneria elettrica e nella produzione di batterie. Nel 2024 ha raggiunto un fatturato di € 4,7 miliardi. Il Gruppo Dürr conta oltre 18.400 dipendenti e 139 sedi commerciali in 33 paesi. A partire dal 1° gennaio 2025 le precedenti divisioni Paint and Final Assembly Systems e Application Technology sono state fuse per formare la nuova divisione Automotive. Dalla data sopra citata il gruppo Dürr opera quindi sul mercato con quattro divisioni:

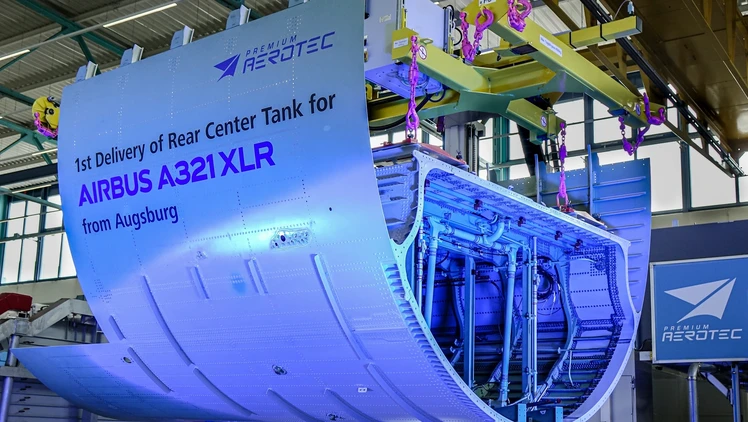

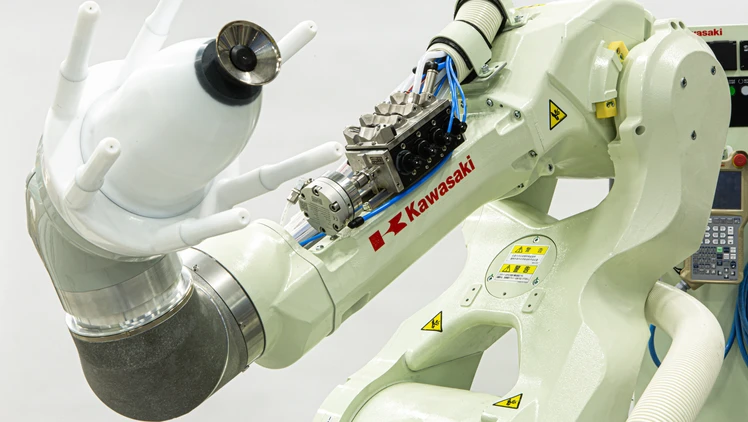

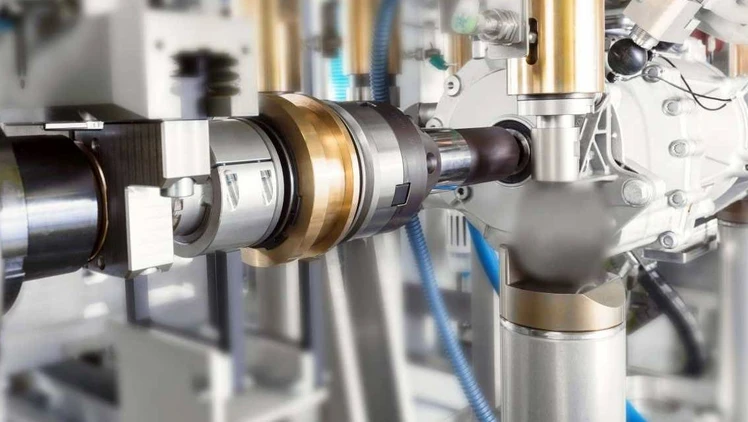

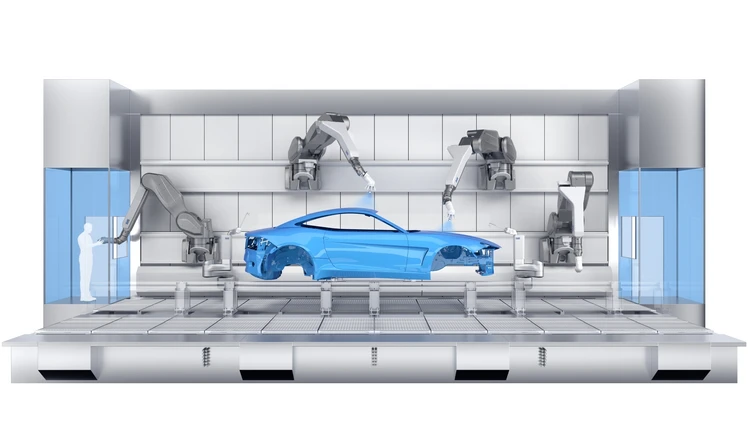

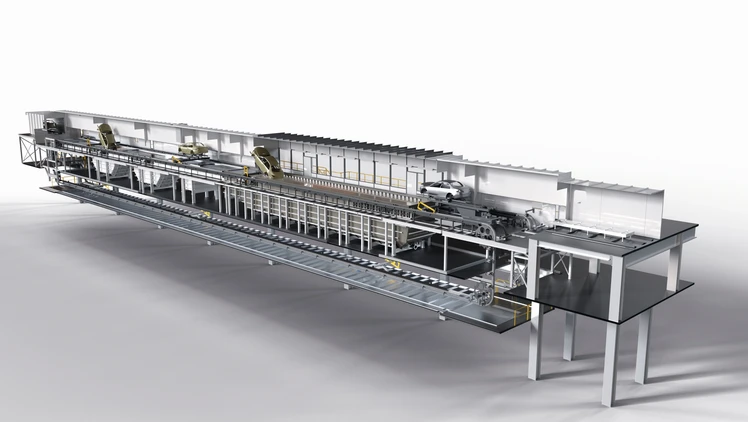

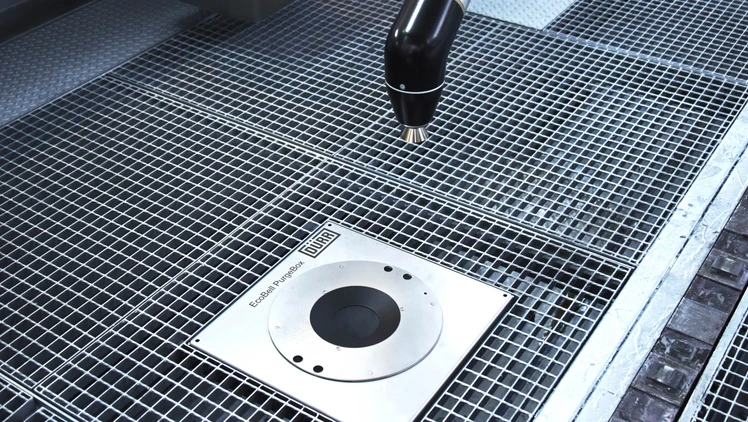

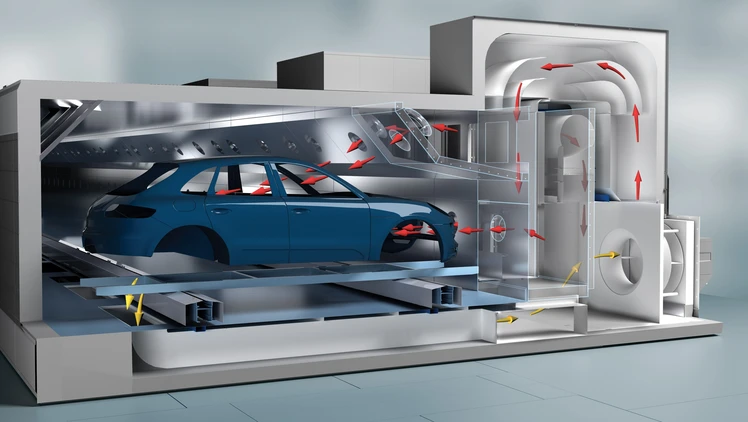

- Automotive: tecnologie di verniciatura, assemblaggio finale, collaudo e tecnologie di riempimento

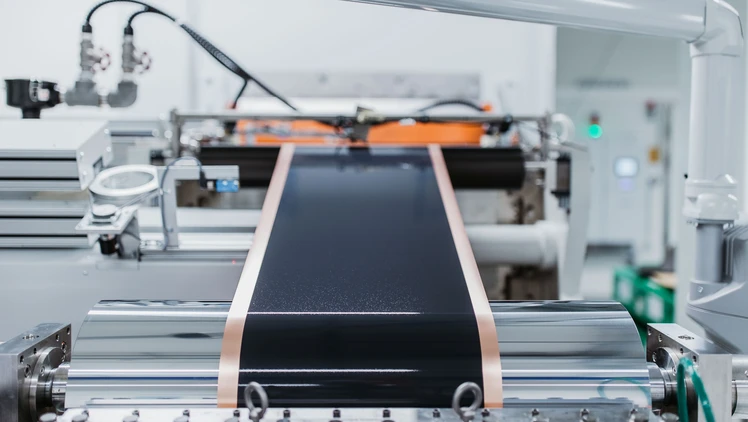

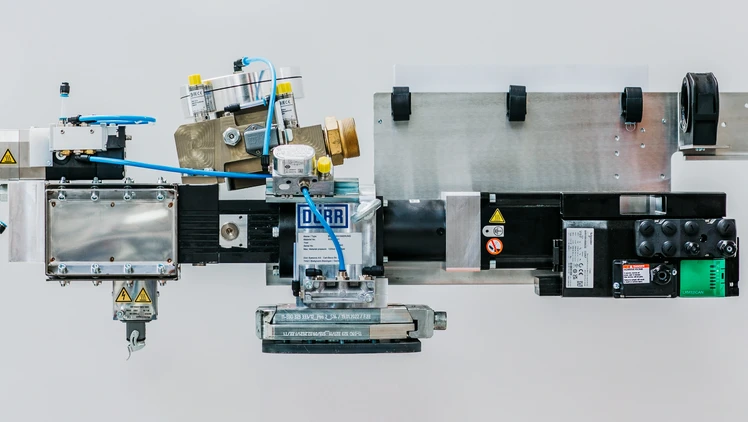

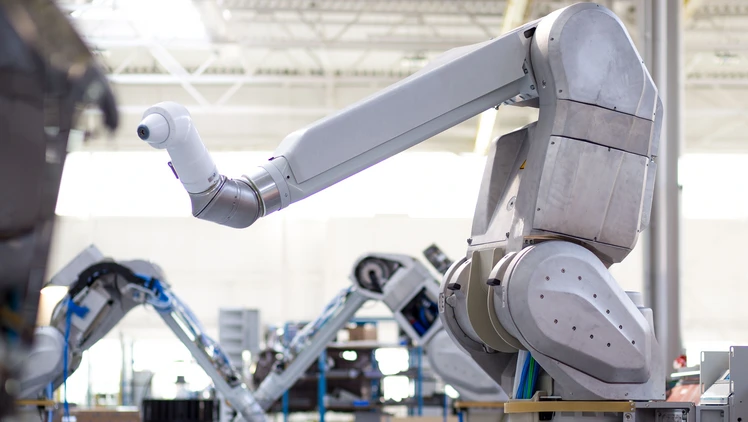

- Industrial Automation: sistemi automatizzati di assemblaggio e test per componenti automobilistici, dispositivi medici e beni di consumo nonché tecnologia di bilanciamento e sistemi di rivestimento per elettrodi batterie

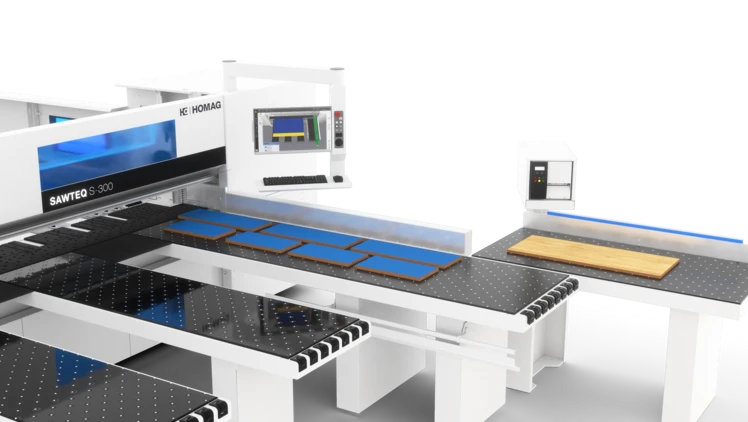

- Woodworking: macchine ed attrezzature per l‘industria della lavorazione del legno

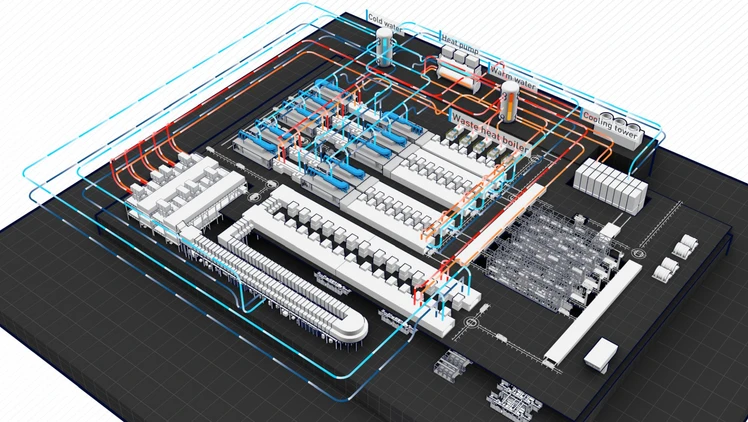

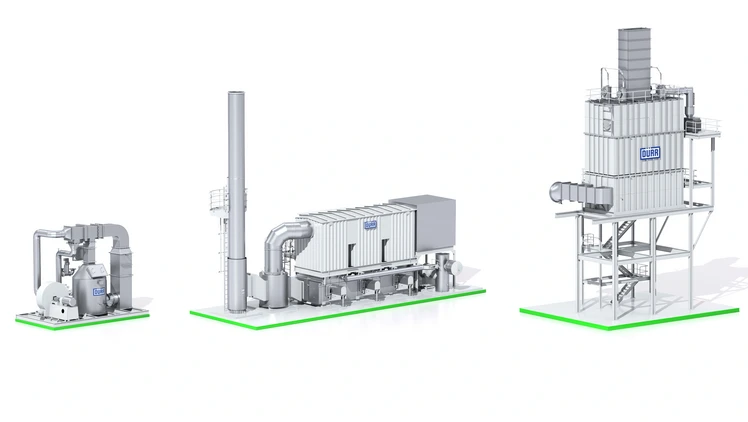

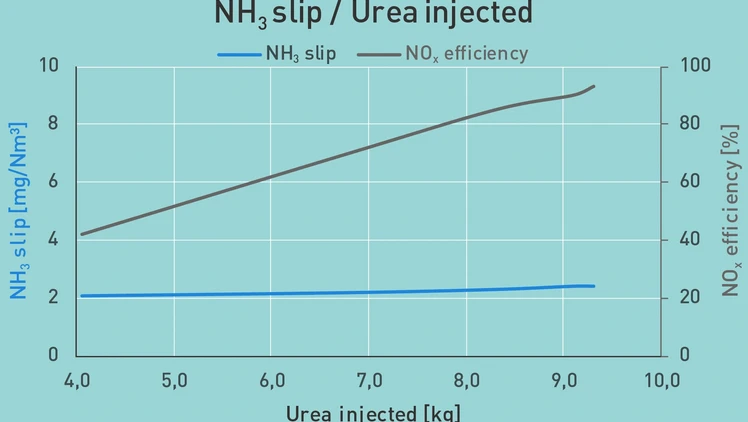

- Clean Technology Systems Environmental: sistemi di controllo dell’inquinamento atmosferico e per l’abbattimento del rumore