PT/EC conveyors

The demands placed on the conveyor system in dip systems for pretreatment (PT) and electrocoating (EC) are as diverse as the systems themselves. Very different technologies are used depending on throughput, process sequence and quality requirements.

Dürr has revolutionized the market with RoDip® M and RoDip® E and is a leader in rotation conveyor technology. Moreover, our portfolio for PT/EC includes all other common systems, such as pendulum conveyors, AirBiDip, EMS, Power & Free, as well as hoisting cranes.

RoDip® M

RoDip® M is a mechanically driven rotation conveyor with a robust chain drive.

Learn more here...

Power & Free

Dürr supplies Power & Free systems at the customer’s request. This robust system is easy to maintain and use.

Electric Monorail System

Dürr offers electric monorail systems (EMS) that are especially adapted to the needs of pretreatment and electrocoating. The trolleys are optimally protected against vapors. Electric chain hoists lower the body into the dip tanks. The solution with EMS is a variant with a minimal system length and is suitable for systems with low throughput.

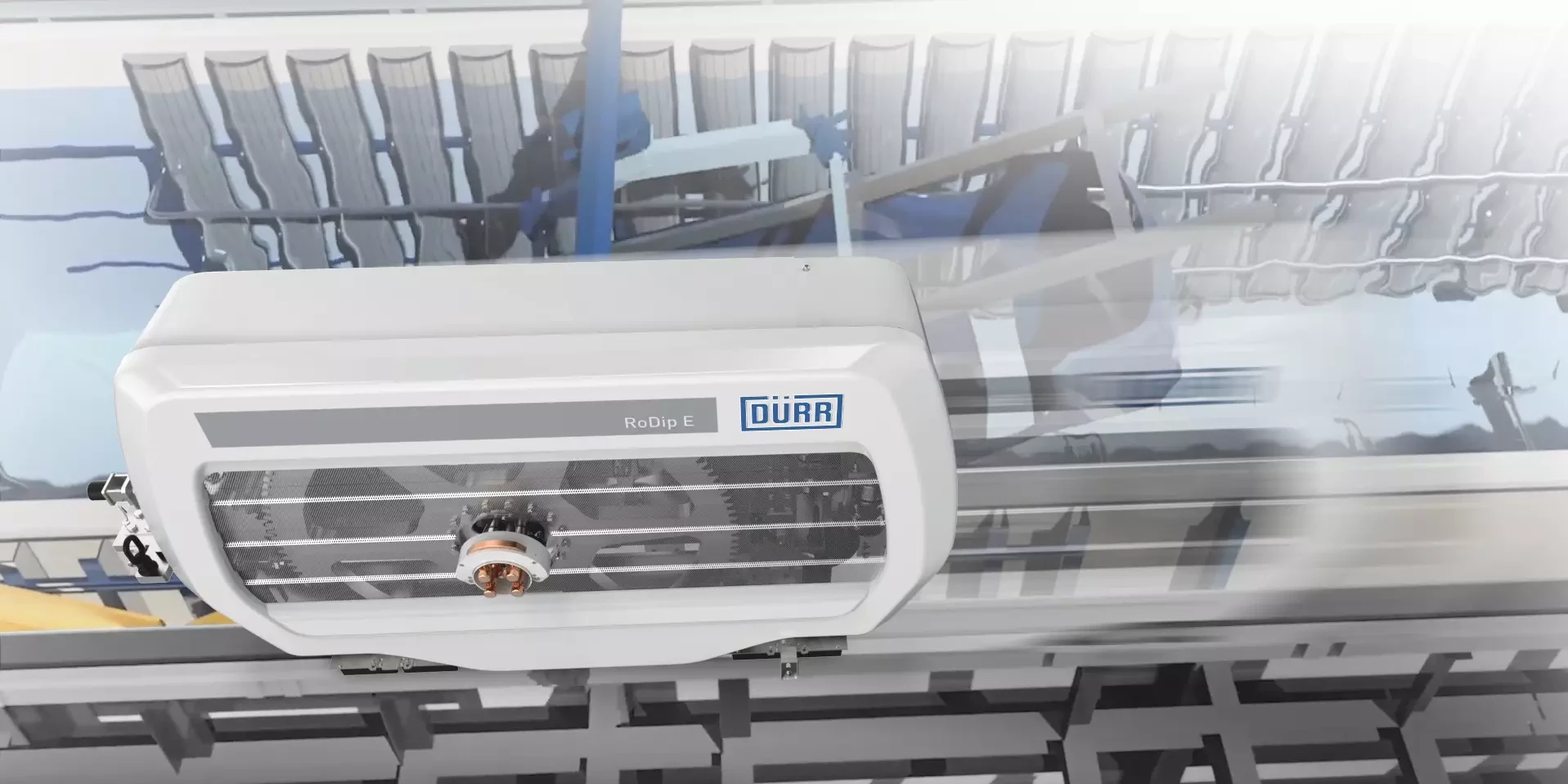

RoDip® E

RoDip® E is based on individually programmable, electrically powered trolleys.

Learn more here...

Pendulum Conveyors

The body is suspended on a chain-driven pendulum pair and transported through various dip tanks. We offer pendulum conveyors with bottom or side return run (AirBiDip).

Hoisting Cranes

Hoisting cranes are suitable for special requirements, in particular for very long vehicles or low throughputs. The vehicles are conveyed transversely from one processing tank to the next, permitting a compact layout with short conveyor sections.