Electrode production has so far relied almost exclusively on wet coating, in which the cathode and anode material is applied as a solution to metal foils and then dried in an energy-intensive process. The technology developed by Dürr in collaboration with partners does not require solvents or drying ovens, as it produces the electrodes from a dry powder mixture. The dry battery material is pressed into a film using the Activated Dry Electrode® process by development partner LiCAP Technologies. The new X.Cellify DC development covers all process steps – from dosing, film formation, and densification to lamination onto the collector foil.

Less energy, less production space

Dry coating offers clear advantages over conventional wet coating in electrode production: it reduces space requirements by up to 65% and lowers energy consumption by up to 70%. These savings are mainly due to the elimination of dryers and solvent recovery. "The successful proof of concept is a major step forward for us. We have demonstrated that the new kind of dry coating with free-standing film works reliably and delivers consistently good quality. It can be scaled up, making it the basis for initial pilot projects in industry," explains Bernhard Bruhn, Vice President of Dürr's Global Business Unit LIB. The process is suitable for today's lithium-ion batteries and also for solid-state batteries.

Free-standing film reduces scrap

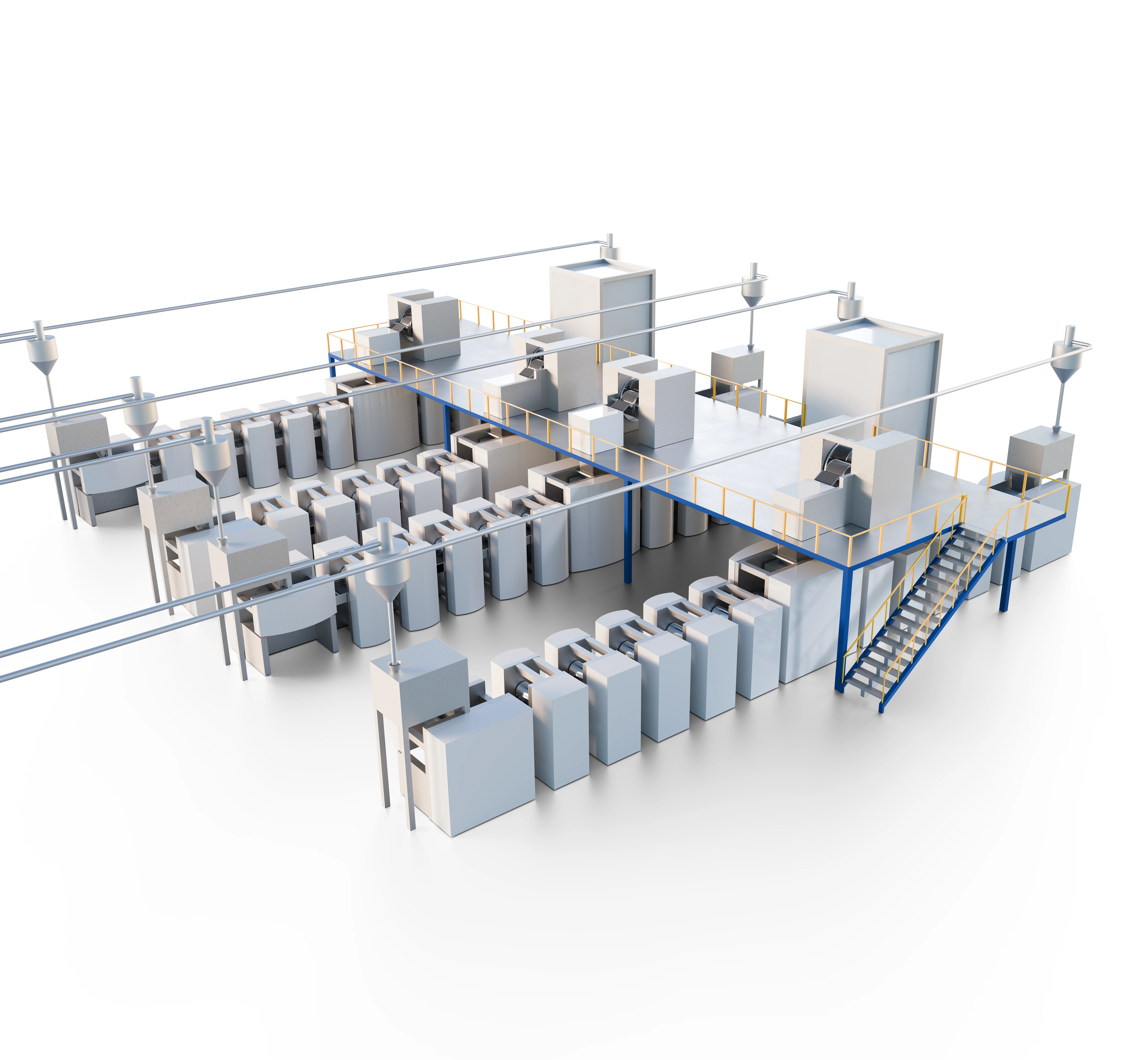

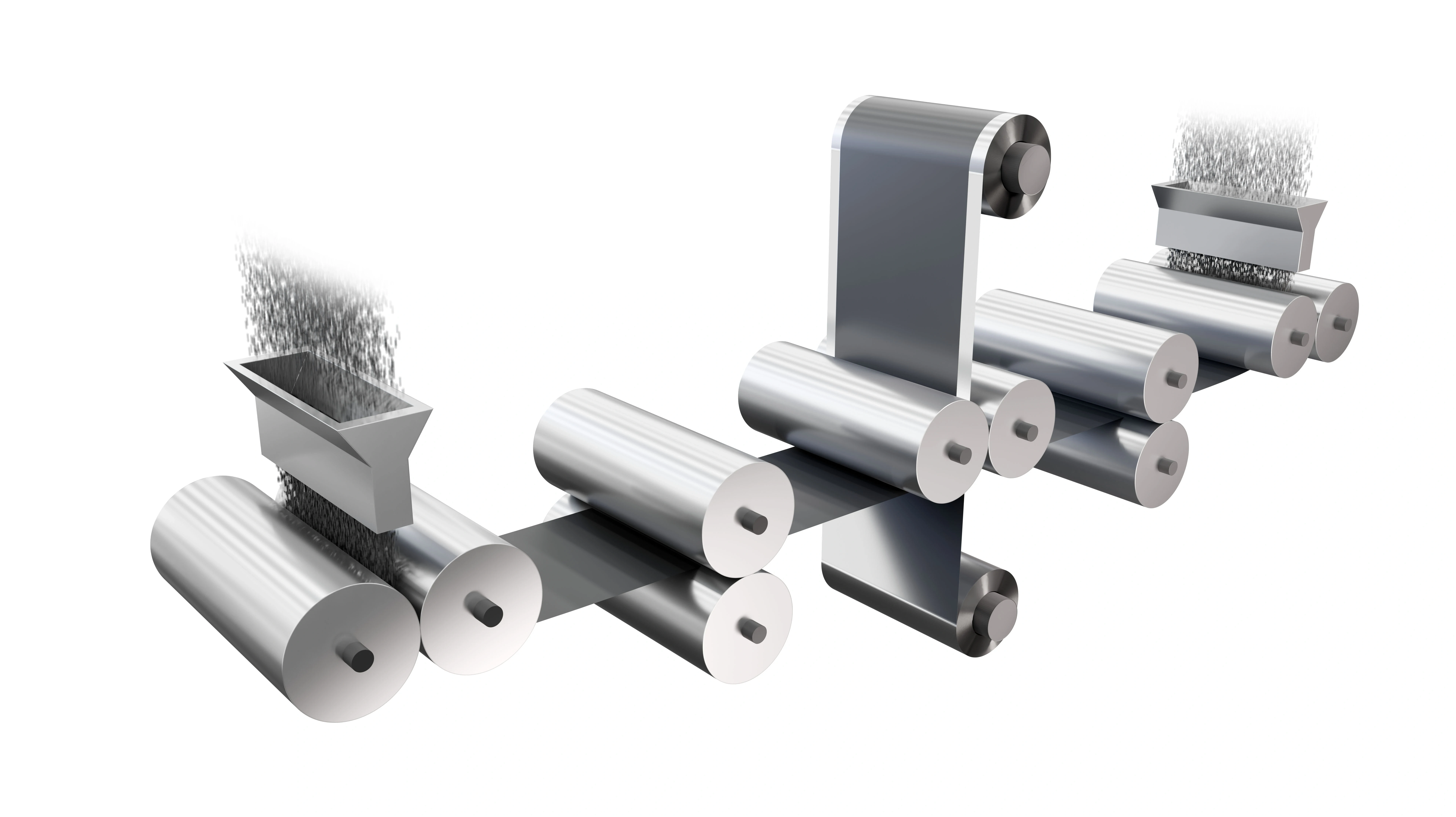

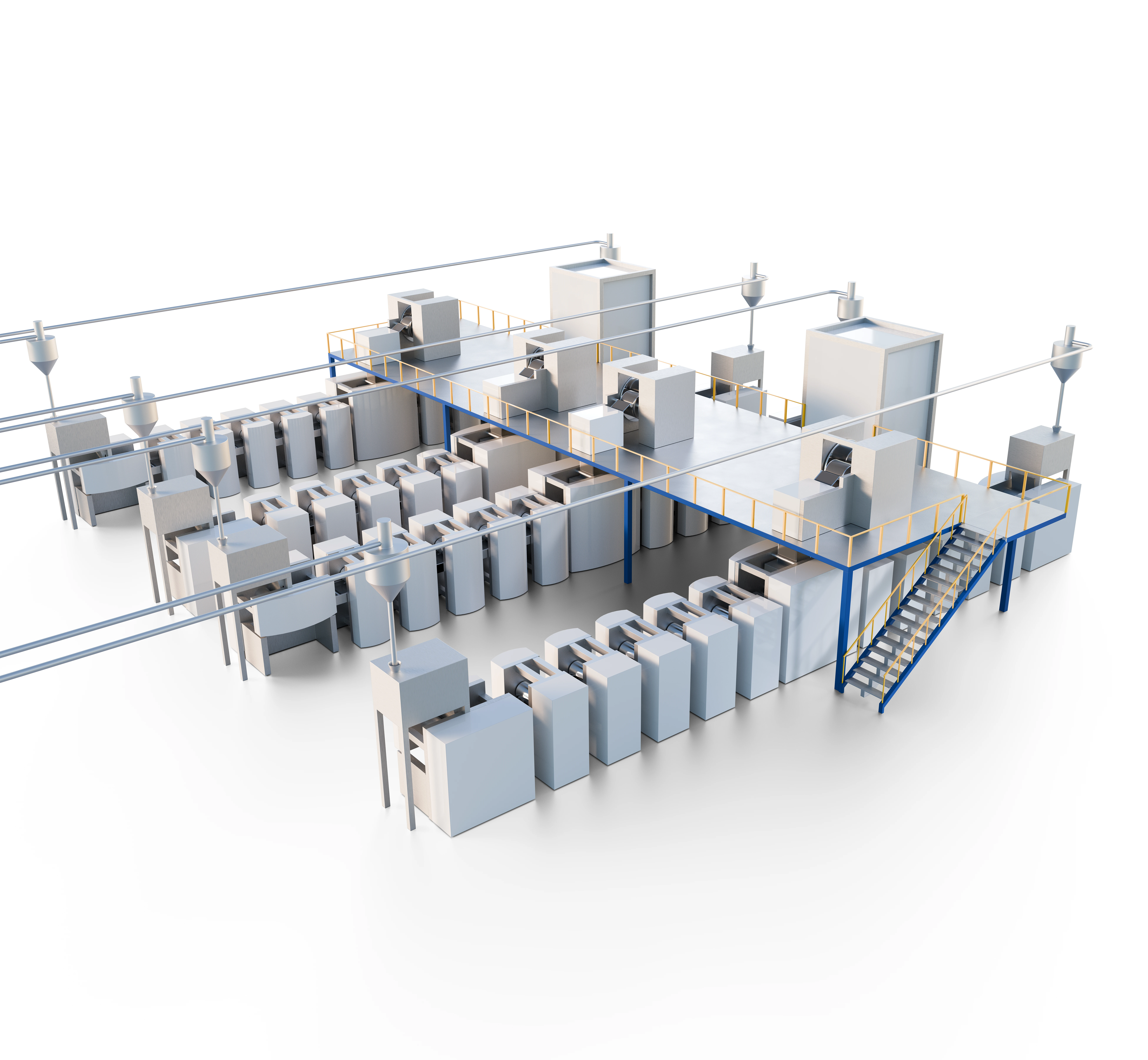

The proof-of-concept plant is located in Chassieu in southern France, in a dry room environment at Ingecal, a Dürr Group company specializing in calender technology. Calenders are machines with rollers that compress materials into an even layer. Dry coating starts with film formation: A horizontal calender forms the dry powder into a film. It is referred to as “free-standing” because it runs through the machine without a carrier foil. In the second step, additional calenders compress the film to the desired layer thickness, density, and porosity. Finally, one film is laminated onto the collector foil from each side – thus producing the electrode. “Since we don't need a carrier foil until the final step, we can return the film to the process in its entirety if it does not meet the desired specifications. Thanks to the closed loop, no valuable active material is lost and we significantly reduce waste – an important point in battery production,” explains Bruhn.

Improved further processing

The special characteristic of X.Cellify DC lies in its web guidance: the system transports the free-standing film in a self-supporting manner and compresses the film before it is applied to the current collector. The subsequent lamination onto the current collector requires less force than calendering in the wet coating process, which means that the foil does not deform – improving its processability for the downstream process steps of notching and stacking.

Combined strengths

The new approach to dry coating combines Dürr's expertise in electrode manufacturing and system integration, Dürr Ingecal's high-precision calenders, and LiCAP's patented Activated Dry Electrode® technology. “To take the next step, we are actively seeking pilot partners in the industry for gigawatt-scale projects. This will enable us to bring the technology into real production environments – whether for electric cars, stationary storage or other applications,” says Bernhard Bruhn. Dürr is thus ready to partner in the next generation of battery production – with solutions for wet and dry coating.