Paint separation with disposable cardboard filters

Nov 18, 2020

Cost-efficient and environmentally friendly: dry separation with EcoDry X and EcoDry Rack

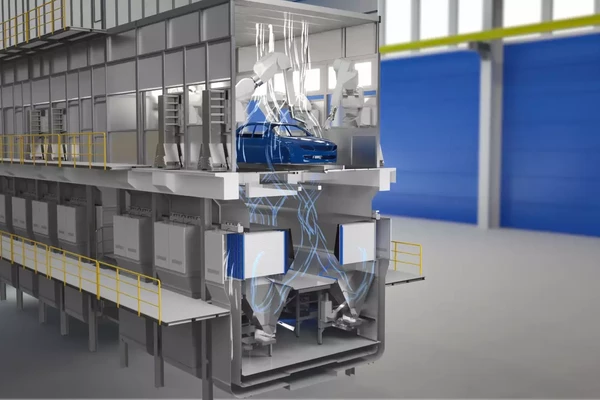

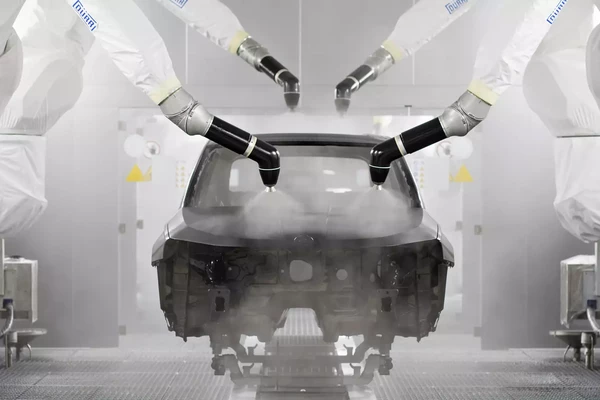

Ten years ago, Dürr revolutionized the world of paint separation with the EcoDryScrubber. This high-tech solution provided the starting point for a further two dry filter systems, the EcoDry X and EcoDry Rack. Together with the EcoDryScrubber, this dry separation family covers the most diverse customer requirements and budgets.

All of Dürr’s experience as a pioneer of dry separation is built into the → EcoDry X and EcoDry Rack processes. In 2010, Dürr developed an efficient, environmentally friendly alternative to wet separation with this technology. The fully automatic → EcoDryScrubber was the first member of Dürr’s dry separation family. Since the requirements of OEMs vary worldwide and from system to system, Dürr added a further two processes to its product portfolio – that use disposable cardboard filters for paint separation. The EcoDry X makes the innovative technology available to customers with a preference for a technologically less complicated and more cost-effective system. The EcoDry Rack is particularly suitable for smaller paint shops with lower production volumes and minimal overspray.

EcoDry X: cost-efficient and robust

The EcoDry X dry separation system requires very little up-front investment, but still benefits from the energy-saving potential offered by a dry separation system unprecedented before the EcoDryScrubber. The consumption of electricity, thermal energy and water is significantly reduced. Furthermore, the EcoDry X does not require any chemicals at all. The EcoDry X is designed for simplicity; it takes very little effort to achieve the best results and requires very little training to use.

Easily exchanged

EcoDry X uses easily exchanged disposable cardboard filters, which can even be changed during production if necessary. Six filter boxes are always integrated in a mobile trolley. Indicator lights on the system and on the control panel show when the filters are saturated. An employee then manually undocks the trolley and simply replaces it with a trolley with fresh filters. Replacement takes just a few minutes and is so easy that it can be done while production is still underway.

Filter boxes for the highest standards

Dürr places great importance on being able to offers its customers a carefully considered and cost-efficient overall system. In the case of the EcoDry X, this also includes the disposable filter boxes. Following intensive development work, the third generation of the X500PV is now on the market. The filter offers impressive versatility as well as very good efficiency combined with high absorption capacity for the most common automotive paints – good news for downstream filter stages and ultimately the wallet. Dürr deliberately decided to use standardized filters. For example, the system can also be equipped with third-party filter boxes. The car manufacturers can purchase the cardboard filters wherever they want, and have the greatest possible control over costs.

EcoDry Rack: the space-saving alternative

The sister product to the EcoDry X is the EcoDry Rack. It is based on the same filtration technology as the EcoDry X, and therefore offers similar performance and efficiency. In contrast to the EcoDry X, the EcoDry Rack has permanently installed filter walls instead of mobile filter trolleys, which saves space and lowers investment. A precondition is that the volumes of overspray accumulating in the paint booth are not too high so that the filters can be changed during production downtimes (e.g. at the weekend). The EcoDry Rack is therefore particularly suitable for special and contrast paint jobs as well as smallest series.

Replacement during production downtimes

The filter boxes of the EcoDry Rack are easy to handle, from procurement right through to disposal. The boxes are located in a filter frame in the separation level of the paint booth, with the second filter stage consisting of pocket filters installed directly behind. The paint booth system keeps the worker in charge informed about the level of saturation of the filters. If they need to be changed, this can be scheduled for production downtimes. Once all the filters have been replaced, production can be resumed.

The compact design of the EcoDry Rack makes it possible to build the dry separation technology below the application level in the tightest of spaces, for example in the old pits of a web scrubbing system.

The two solutions EcoDry X and EcoDry Rack have no unnecessary extras, resulting in two extremely robust separation technologies.

This is the third part in our dry separation series, published this year to coincide with the ten-year anniversary of the EcoDryScrubber. In the → first part you can find out more about dry separation in general, while the → second part focuses on the technology of the EcoDryScrubber.