Our portfolio for fine chemistry

Fine chemicals are a trade category of pure chemical substances. There are very many different fine chemicals which have a guaranteed degree of purity and undergo complex syntheses during production. Fine chemicals are mostly expensive and only available in small quantities. Applying the right emission control equipment for the chemical and pharmaceutical industry requires a thorough understanding of the process and system requirements, combined with the ability to provide custom solutions.

Environmental compliance solutions for chemical processing

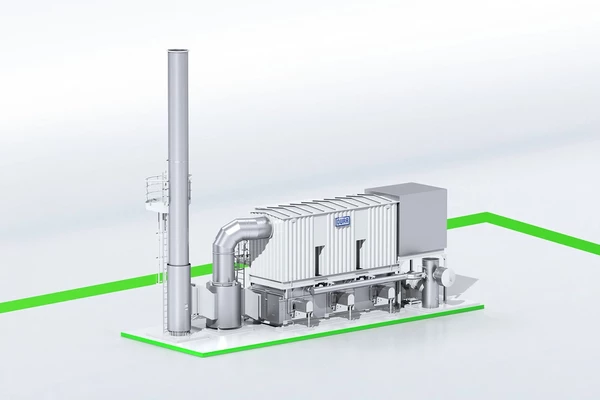

Thermal Processes

Dürr’s regenerative, recuperative, catalytic, and direct-fired thermal oxidizers treat VOC emissions in the gas or liquid phase to meet the most stringent environmental emission limits and regulations. With its offices throughout the world, Dürr is familiar with specific regional requirements and works very closely with Engineering, Procurement, and Construction (EPC) firms to design, develop, and execute complete air pollution control systems that include oxidizers, NOx control systems, scrubbers, wet electrostatic precipitators, and vapor recovery systems. Our equipment is designed to provide maximum uptime, which is essential to chemical and pharmaceutical production facilities.

Our thermal oxidizer systems are used in situations where emissions are released from continuous or batch applications in various petrochemical and chemical processes, along with primary and secondary pharmaceutical manufacturing. Dürr also serves the chemical processing industry with the largest trained field service team which is strategically located worldwide.

The scope of our supply and installation services includes turnkey operations with vent collection systems, vent conditioning with LEL dilution control, pre- and post-oxidation scrubbing for acid gas removal, flame arrestors, explosion relief, particulate removal, with the associated project HazOp and SIL reviews and project documentation packages to meet market demands.

Carbon Adsorption Solvent Recovery, Separation, and Purification

Carbon adsorption systems, both regenerative and non-regenerative, capture vapor-phase emissions of volatile organic compound (VOC) solvents from solvent-based processes. The solvents are prevented from entering the atmosphere, in order to ensure compliance with environmental laws and regulations. In a regenerative carbon adsorption system, solvents are adsorbed on activated carbon. When the carbon is saturated with the solvent, it is regenerated with steam and the solvent is recovered as the steam condenses.

Dürr solvent recovery systems offer two key benefits: environmental compliance and reduced operating costs. Water-miscible solvents can be purified on-site with our distillation equipment, which makes it possible to reuse them and also yields a dedicated ROI. As for non-water miscible solvents, they can be reused without further processing.

Stand-alone Dürr distillation systems purify waste water to make it suitable for disposal, which reduces disposal costs, and also separate out and purify solvents.