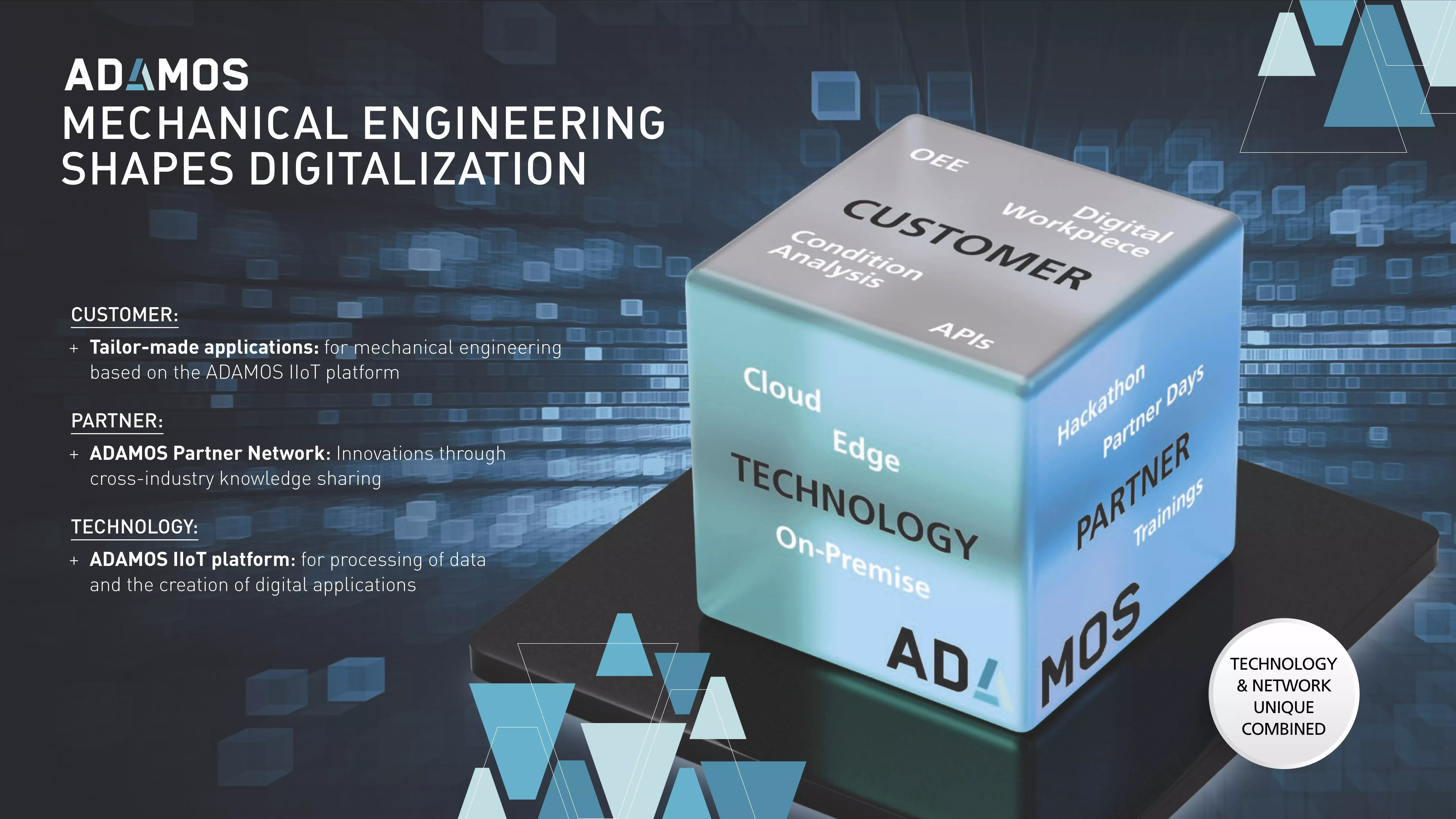

ADAMOS is an open, manufacturer-neutral IIoT software platform, specifically tailored to the mechanical engineering sector and its customers. It offers simple digitization of production to users of machines and manufacturing facilities.

The ADAMOS platform can be used to interconnect machines, enabling them to exchange information via the Internet. By means of data generated through ADAMOS, users are able to utilize digital services and thus increase their production efficiency. Examples include apps for predictive maintenance and for maximizing machine utilization.

Ralf W. Dieter, CEO of Dürr AG and Chairman of the ADAMOS Advisory Board, says: “ADAMOS is the mechanical engineering industry’s collective response to the challenges of digitization. At ADAMOS, we all learn and benefit from each other, because digital transformation is so complex that companies shouldn’t have to tackle it on their own.”

To allow interested mechanical engineering firms an easy way into platform economy, ADAMOS has now also added special Digital Transformation Services to its portfolio. ADAMOS thus supports companies in implementing digital business models by offering training, consulting and implementation services. “ADAMOS is a service-oriented digitization partner for the mechanical engineering industry. Thanks to our cooperation model, members can save costs and speed up the development of apps for production optimization. In addition, we are together promoting the establishment of digital business models”, according to the two ADAMOS Managing Directors, Dr. Tim Busse and Dr. Marco Link.

ADAMOS was founded in 2017 by the mechanical engineering firms DMG MORI, Dürr, Zeiss and ASM PT, together with Software AG. The latter, enabling partner and Germany’s second largest software house, provides central software modules for the platform. The companies that are part of the ADAMOS network cooperate closely in developing apps and digital business models.