China is increasingly reconciling economic dynamism and environmental protection. Its aim in doing so is to improve the air quality in major cities with low-emission production processes. This is also true of Beijing, the location of BBAC’s recently commissioned paint shop. That is why the German-Chinese automotive joint venture focused on two environmental issues from the beginning: high energy efficiency during production and efficient exhaust air purification.

In the new paint shop, which has an hourly throughput of 30 vehicles, BBAC is using the Integrated Paint Process (IP2) which has been tried and tested at Mercedes-Benz. This process eliminates the application and baking of the primer, since it is integrated into the base coat. This reduces emissions and energy consumption significantly. It also makes for a more compact system design, since the entire primer line including the associated oven is not needed. This saves infrastructure space and already lowers energy consumption and CO2 emissions during the construction Phase.

Energy savings of up to 60%

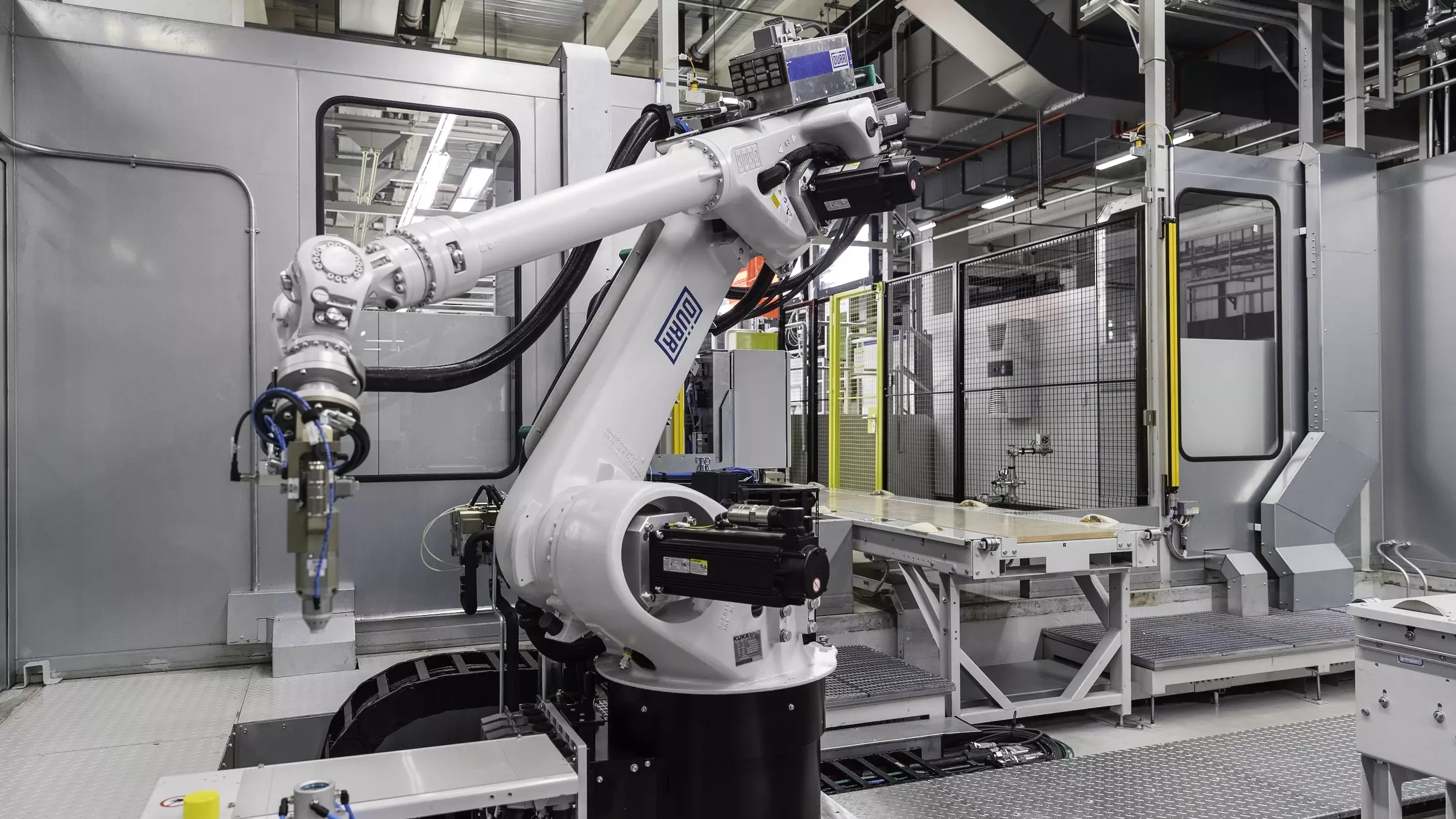

The technology is also designed for sustainability in the PT/ED phase. The RoDip® rotational system used during pretreatment and cathodic dip-coating eliminates entry and exit inclines as the car bodies are introduced at a steep angle and rotated through 360°. This enables shorter dip tanks, which need less water and energy as well as fewer chemicals for the initial fill and during operation. BBAC is also using an environmentally friendly solution in the spray booths with water-based paints applied by painting robots using the EcoBell2 high-speed rotating atomizers. With its flexible spray jet setting, the EcoBell2 can handle different painting tasks with the best quality and – thanks to the high degree of transfer efficiency during application – economically. Any paint overspray is separated in a ressource saving manner. The dry separation system EcoDryScrubber binds the overspray with limestone powder in a process involving no water or chemicals. This means that the painting booth can be operated with 80% recirculated air, which in turn lowers air conditioning costs and offers energy savings of up to 60%.

Heating ovens with exhaust air

BBAC is also setting standards when it comes to emission control. The painting booth is equipped with Dürrs’ compact exhaust air purification system for removing the solvents (VOC) from the exhaust air. Due to the booth air recirculation, the exhaust air requiring abatement is already concentrated. The Ecopure® KPR VOC concentrator system, combined with a downstream thermal oxidizer, the Ecopure®TAR, allows for highly efficient VOC removal. This combination reduces the size of the thermal oxidizer by 80% compared to conventional VOC abatement systems connected to spray booths without air recirculation. The exhaust air from the ovens is abated by the Ecopure®TAR, an integral afterburning system with heat recovery, and is then reused for heating the oven.

The new paint shop is the second contract from BBAC. Dürr constructed a first paint shop in Beijing in fall 2015, just three miles away from the new one. The lessons learned during this project, the synergies in planning and execution, and largely identical project teams on both sides ensured such a smooth process that the start of production for the second project was achieved much earlier than planned.