As general contractor, Dürr supplied the entire paint shop, including application technology. The concept of sustainability is assured already in the PT/ED area. The Ecopaint RoDip rotational dip process is used during pretreatment and cathodic dip-coating. Due to the complete rotation of the body in the bath, RoDip requires no entry or exit ramps. The tanks are therefore up to 6 meters shorter. This smaller volume of the dip tanks reduces the amount of water and chemicals required and as a result also means less energy consumption for the conditioning of the bath. RoDip not only reduces the unit cost but also provides the best possible corrosion protection through an optimized immersion, flooding, and draining process.

Automation starts with the LASD (Liquid Applied Sound Deadener), the interior sealing and the underbody protection. Two Dürr robots are doing this work at every station. Subsequently, the interior of the bodies is dusted by an EcoBlow-Off system. Horizontal and vertical high-pressure nozzles blow large volumes of air into and onto the body at high velocity and remove dust and dirt. Afterwards, the EcoClean cleaning system removes the dust from the outside of the body by means of feather rollers.

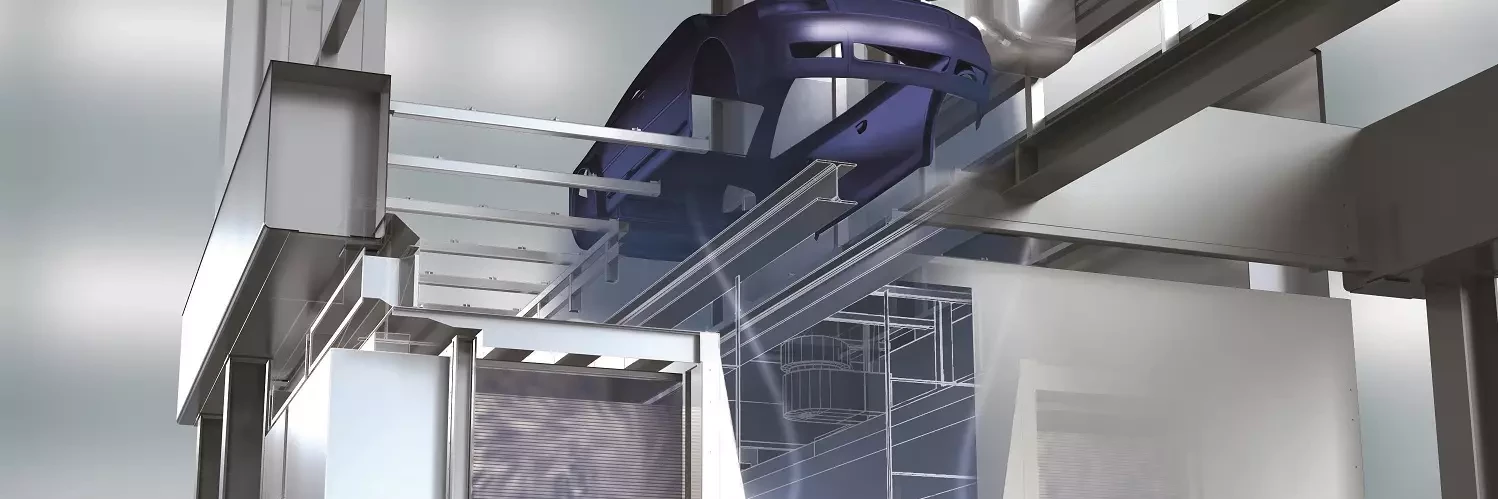

The application of the primer and base coat to the outer shell is fully automated with a total of 16 EcoRP L033 painting robots. The proven EcoBell3 atomizer with external charging is used in both cases. The clear coat is also applied by ten EcoRP L033 painting robots. These use direct charging, however. Full automation of exterior painting is imperative to facilitating the two-tone painting of the car bodies as required by the customer.

Like many other car manufacturers, CJLR relies on the EcoDryScrubber. This dry separation of the paint overspray is carried out completely without water and chemicals. This allows the paint booth to be operated with up to 95% recirculated air. Due to the lower effort for air conditioning, the EcoDryScrubber saves up to 60% energy in the paint booth. 75 painting lines around the world already use Dürr’s dry separation system or are currently being equipped with it.

Chery Jaguar Land Rover has already taken this Eco+Paintshop into operation. It is characterized by particularly low usage of energy, material, water, and other resources and thus saves costs. Vehicles of Jaguar brand, Land Rover brand, and joint venture brand will roll off the assembly line in Changshu. This wide production range proves the flexibility of the system.