Dürr’s history in China began in 1983 with its first project: the delivery of ovens to Volkswagen in Shanghai. The opening of the Dürr office in Shanghai in 1995 marked the beginning of formal localization, followed by the founding of Dürr Painting Systems Engineering (Shanghai) Co., Ltd. in 1997. In 2017, the opening of the Dürr China headquarters and R&D center further boosted local innovation. Today, Dürr China has grown from a small team to nearly 1,200 employees. The company is active in research and development, manufacturing, and services, and is now expanding into new areas such as battery production.

Innovation driver for industrial change

Dürr innovations always focused on high functionality, quality, operating cost savings, and, in recent years, increasingly on sustainability.

A variety of market-changing developments have shaped the industry. The RoDip® rotation dip coating system was the first to enable 360° body immersion, improving coating uniformity. Continuous improvements to Dürr’s atomizers have increased clear coat transfer efficiency to over 90%. The groundbreaking EcoDryScrubber system replaces conventional wet separation, eliminating the need for water and chemicals, and setting new standards in energy efficiency. The EcoInCure oven uses cross-flow to reduce line length and gradually incorporates green energy for efficient, zero-carbon production. EcoPaintJet Pro technology enables fully automatic, overspray-free color spraying for the first time.

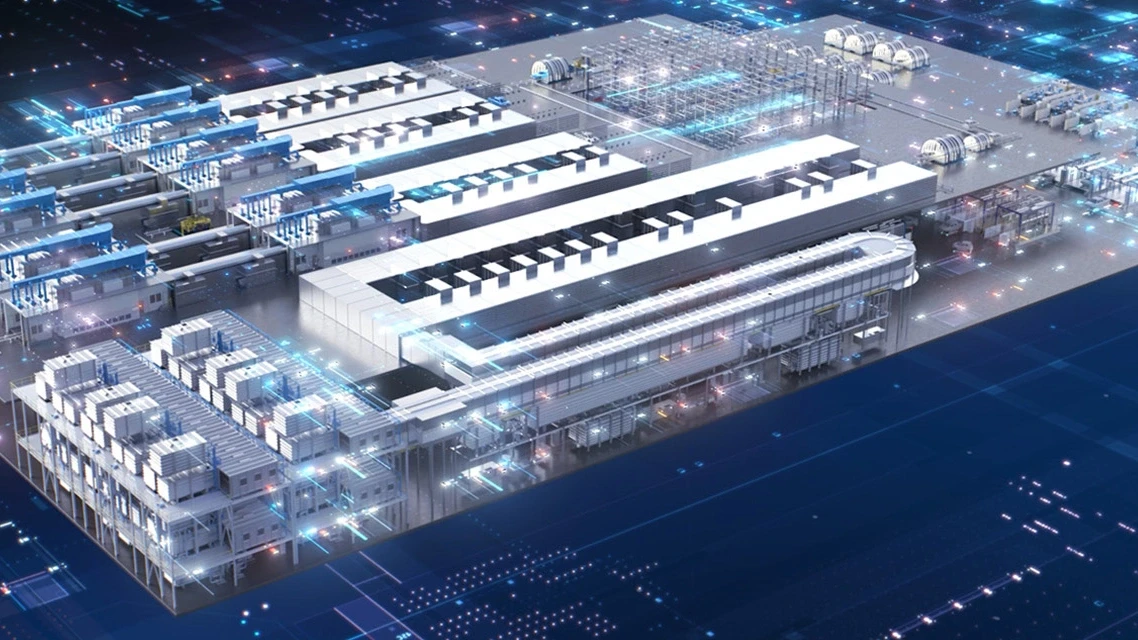

The rapid progress of digitalization in recent years has led to more advantages in plants: Combined with the DXQ digital platform Dürr’s "paint shop of the future" replaces linear manufacturing processes with flexible, dynamic systems for the mixed production of various car body shapes and a comparatively easy quick adaptation to changing production quantities. But Dürr offers more than paint shops. With its “NEXT.assembly” product line, Dürr provides a complete portfolio for final assembly, along with end-to-end solutions that reimagine conventional final assembly layouts.

Local expertise, global impact

From the initial introduction of foreign technologies to independent local implementation, Dürr China has built a nationwide service network, integrated itself deeply into the local industrial ecosystem, and established a strong service base. In line with its customer-first philosophy, the company has completed over 100 turnkey painting and assembly projects for both traditional automotive manufacturers and new energy vehicle brands. Dürr provides comprehensive professional support throughout the entire product life cycle, including system analysis, production capacity optimization, and more.

Thanks to its local experience, Dürr China has become a global systems center, coordinating the Southeast Asian market and actively exporting expertise developed in China. In recent years, the company has executed more than 50 multinational projects across over 20 countries and regions—including the Stellantis plant in Morocco and the BYD factory in Europe—efficiently supporting global industrial modernization.

Deepening local innovation for the future

Looking ahead, Dürr will further strengthen its localization strategy, make better use of global resources, and support both Chinese and international automotive manufacturers in their global growth. The company will invest further in talent development and build high-performance teams to enhance service quality.

Michael Baitinger, CEO of Dürr China, said: “Over the past thirty years of our partnership with customers in China, we have been honored to witness—and be part of—the automotive industry’s transformation. In the future, we will open a new chapter of localization, making more progress in R&D, production, and open collaboration, so that we can drive the sustainable development of the industry together with our partners.”