The ever growing range of colors in body painting entails not only special paints but also increasingly small-batch colors. For such applications, Dürr offers the EcoSupply P standardized modular paint supply system. The system, which employs pig technology, is equally suited to water-based paints and solvent-borne paints.

“Dürr has installed special paint supply systems for automobile manufacturers all over the world. Now, we’ve received our largest individual order for the EcoSupply P yet. For the first time ever we are equipping an entire paint shop for body and bumper painting in the US with a total of ten systems,” says Dr. Hans Schumacher, President & CEO of Dürr’s Application Technology division, describing the global success of the efficient system.

Compared with the previous ring-pipe systems, Dürr pigging systems consume considerably less paint and flushing agent. With the rising prices of special paints, this gives piggable systems a decisive edge - investing in special paint supply systems will pay off very quickly.

In the project, the car bodies are to get fourteen additional small-batch colors, including two applied using what is known as tri-coat premium painting. The process applies different color shades to the body in direct succession during base-coating. Because the existing robots’ paint-ring-pipes can only be supplied with a maximum of twenty colors, the automobile manufacturer is upgrading to piggable systems.

Paint recovery and cleaning using pig technology

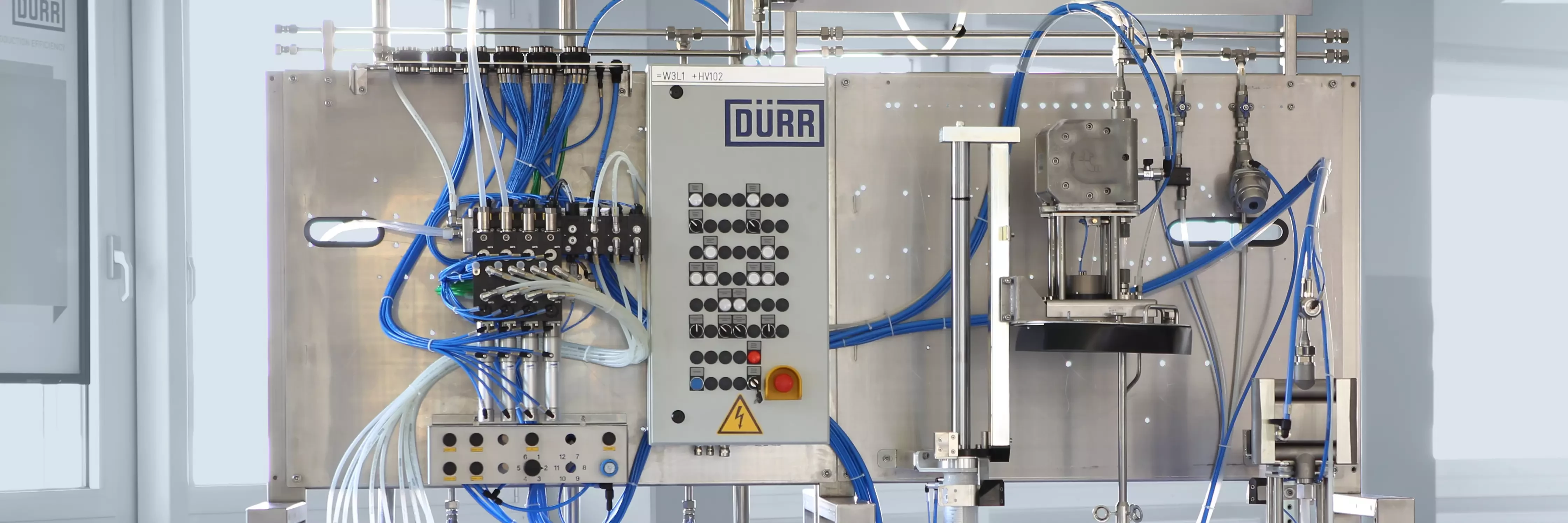

The small-batch colors are painted in batches of 15, 30, or 60 bodies. While the painting process is underway, a second system is already performing the next paint change. The EcoSupply P system delivers the paints by sliding cylindrical pigs through hoses to the paint spray booth - with extremely low paint loss.

The pig destination modules are integrated directly into the Dürr EcoMCC3 color changers, which are installed in the trolley docking station of the existing thirty-two robots on the base-coat lines and the six robots used for bumper painting. When the paint has been applied, the pigs push the remaining paint back out of the hoses. This leaves almost no residue in the process returning it to the paint tanks and cleaning the hoses. The system houses the paint supply stations in a separate paint mixing room beneath the paint spray booth.

Simple to use

Dürr is also supplying the system’s visualization function and the control unit that will in future communicate with the existing plant and robot systems. The visualization function tells the system operator which paint spray booth needs which color. After connecting the paint tanks, a simple push of a button suffices to start the filling process and automates pig-based painting.

The current project takes the number of EcoSupply P systems deployed in the USA to twenty-five in total. In European plants, Dürr’s special paint supply systems have been in use since 1999. During that time, more than 420 systems have been installed at various automobile manufacturers and in plastic parts paint shops in the industry’s supplier sector.