In the paint shop at the Chongqing location, Changan Ford relies on Ford's proven energy efficient 3-wet high solid process. In this wet-in-wet painting process, there is no need to use an oven between painting steps. Ford is also introducing a new 3-wet water-based process at the plant in Hangzhou – also due to new environmental regulations in China.

The use of heat recovery from the oven's exhaust air also saves energy. Changan Ford uses the oven's exhaust heat for heating the supply air of the spray booth. An additional energy saving measure is Ford’s use of air recirculation in the automatic zones of the spray booths.

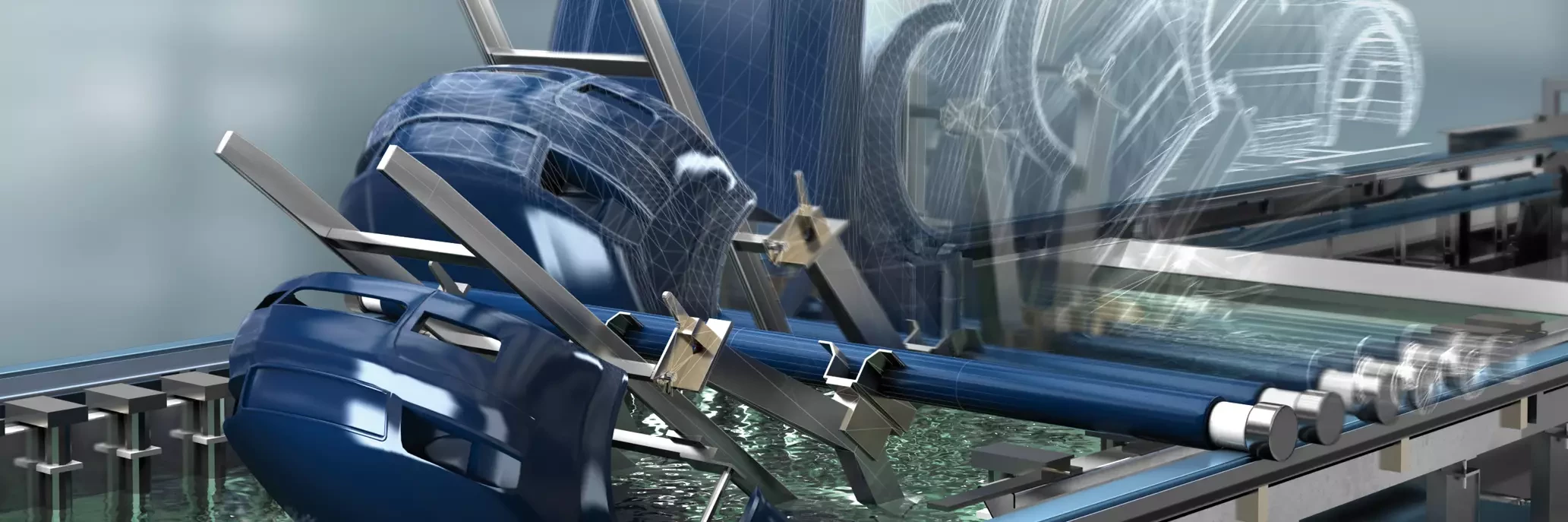

Dürr's established RoDip M rotational dip coating system will be used in pretreatment and electro dipping. The rotational movement of the car body in the RoDip tank guarantees uniform cleaning and coating. RoDip technology thus provides the best possible corrosion protection and a space and material saving plant layout as well, since inclined sections at the entrance and exit of the dip tank are not needed. Through the resulting smaller bath volumes, energy is saved along with space and material.

In Chongqing, the application of primer, base coat and clear coat for the car body shell takes place with 36 EcoRP L033 painting robots. In addition, four EcoRS16 robots are used for applying the underbody protection. In the Hangzhou plant, 92 painting robots are used for primer, base coat and clear coat application. Eight EcoRS16 robots are used for applying the underbody and stone chipping protection. All the robots in both factories will be equipped with the proven high-speed rotating atomizer EcoBell2. Dürr is installing an EcoClean exterior cleaning system for each paint line. This prepares the car bodies for paint application.

The energy-saving plants for the production of Ford’s C or D models will become operational in September 2014 and January 2015. After commissioning in Chongqing, 68 vehicles will be painted per hour, with 60 in Hangzhou. Both paint shops will be run in two shifts. The two orders were placed in the third and fourth quarter of 2012, respectively.