High viscosity sprayable materials such as PVC plastisols are used for sealing to protect car bodies against corrosion and water ingress. For seam sealing the material is applied to overlapping sheet metals on car bodies to avoid gap corrosion due to intruding water.

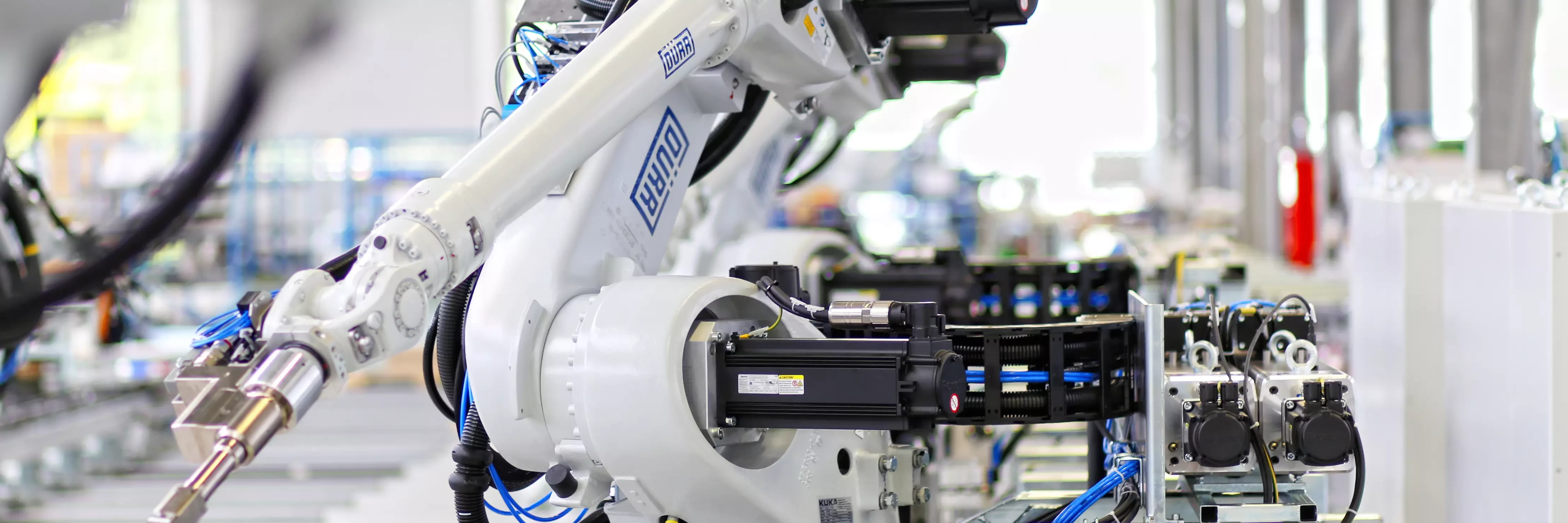

In July 2016, Dürr will deliver its 2,000th robot for sealing application. With its shortened arm 1, the EcoRS 30L16S will seal the welds inside car bodies at Škoda in Kvasiny. The existing sealing plant is currently being expanded for this purpose.

Fully automatic sealing has finally established itself on the market in recent years. More and more car manufacturers are converting their manual sealing stations. “One reason is that robots can apply the seams and coatings much more uniformly and exactly than would be possible with manual application,” explains Dr. Hans Schumacher, president &CEO of the Dürr Division Application Technology.

Dürr has simultaneously tailored the robots to an increasing number of applications. In addition to applying underbody protection and sill coating (PVC and paint), they are also used for liquid applied sound deadener (LASD) application. Robots also play to their strengths when it comes to highly accurate coarse and fine seam sealing, as well as cosmetic seals on doors and lids.

Dürr now employs a new model to meet the special demands inside car bodies. Arm 1 of the EcoRS 30L16S is only 800 mm long. This makes it much easier for the robot to enter the car body. It is simultaneously possible to utilize the existing space much more efficiently when converting existing plants. At the Kvasiny Škoda plant, the smaller robot made it possible to dispense with the floor recess normally required. This reduces conversion costs and shortens the brownfield project duration to three weeks.

The EcoRS 30L16S is equipped with the latest application equipment. The EcoGun2 3D applicator’s streamlined design is free from interfering contours, allowing the applicator with a lance length of 350 mm to penetrate considerably deeper into the car body than before, including into especially tight spaces.

To make the application of viscous material more efficient overall, Dürr also improved its electric EcoShot Meter piston dosing unit. Available in two sizes, this precise system is suitable for most viscous sealing and gluing materials and covers almost all applications as a standard model.

Three EcoRS 30L16S robots operate in the new sealing station at Škoda. Dürr will adapt the existing material supply and conveyor systems to the new system.

“Škoda will benefit in several ways from the conversion to a fully automatic sealing station: The ergonomically difficult working conditions of manual application will be eliminated, seam quality will improve, material consumption will decrease, and the new robot model is already increasing efficiency thanks to the shorter conversion time,” says Dr. Schumacher in summarizing the project.