Robots are asserting themselves in more and more areas of automobile production. In addition to the body shop and paint shop, the processes in final assembly are taking further steps towards automation. For example, robot cells separated by protective grating carry out recurring tasks with the highest repeat accuracy.

However, a fully automated process in final assembly is proving to be difficult. Many work processes require complex operations by the assembly workers; they always have to react to new situations and act flexibly, as appropriate. Collaboration between human and robot, however, opens up further possibilities here.

Higher efficiency in manufacturing

Therefore, workers and robots will work together like colleagues and complement each other on different tasks side by side. Dürr is now taking this step in automobile production. The human-robot teams will collaborate to glue tanks into vehicles. “We are constantly receiving signals from the industry to enhance the efficiency of the assembly process with new approaches in the robot application,” says Dr. Hans Schumacher, president & CEO of the Dürr Division Application Technology, explaining the motivation for entering into the new topic.

Specialists take on the complex assembly processes in the human-robot collaboration. They are required when flexible action is needed. By contrast, robot systems become involved in situations in which humans are under high physical strain or have to work in ergonomically unfavorable conditions. They are convincing whenever the same movements have to be performed over and over again, which requires a consistent rhythm and high reliability.

Therefore, if a robot’s performance capability is used, and at the same time the flexibility of a human can contribute to making the manufacturing process faster, more cost-effective and of higher quality, then the prerequisites for HRC systems are fulfilled.

Robot colleague, please glue

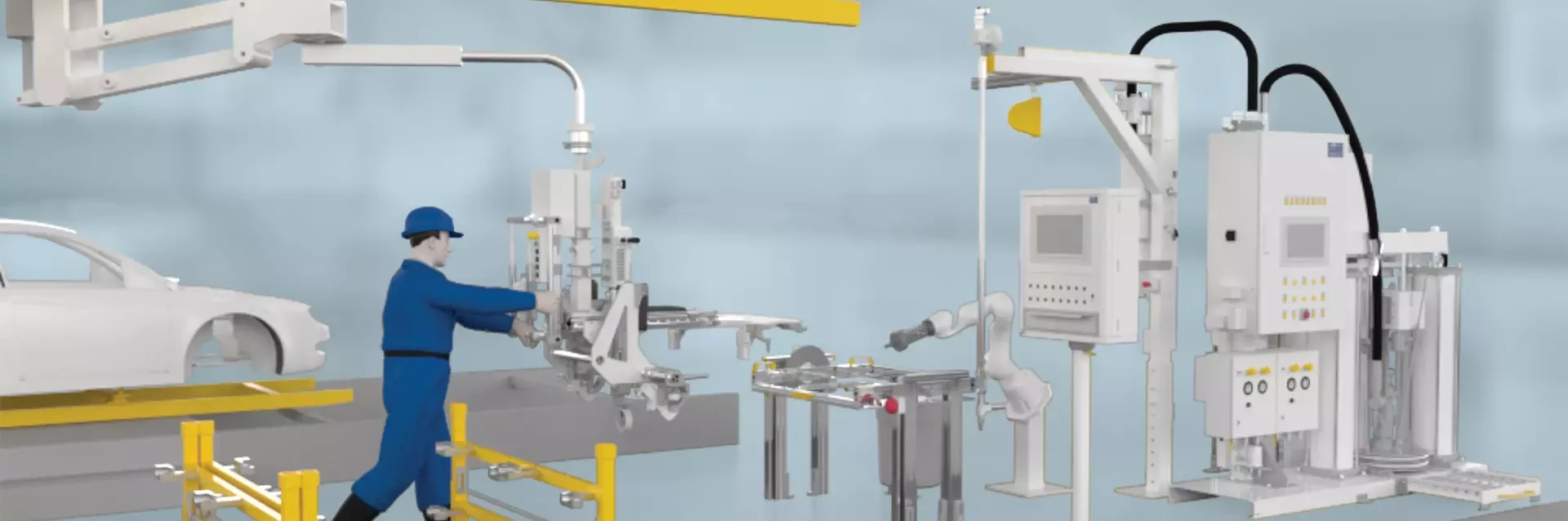

In the new systems blueprint the worker in the assembly shop first moves the tank to the common work area with the aid of a manipulator. He cleans the component and transfers further processing to the machine. After the start signal the robot starts applying the glue bead on the edge of the tank in high uniformity. Sensors on the application head monitor the precise fitting height of the glue seam. Once the mechanical production aid has finished its activity, the specialist fits the tank into the provided position in the trunk. This complex procedure requires the individual capabilities of a human. The manipulator supports him in doing the ergonomically unfavorable movement sequences.

Dürr supplies the plant equipment for the new human-robot collaboration entirely from a single source. Along with the layout concept, this concerns the complete material supply system, the electrically controlled dosing equipment for the speed-dependent controlled flow of glue, as well as the superordinate control unit with the operator panel for handling, gluing and screwing. The application heads, which are designed to be very light for safety reasons and can be turned 360 degrees, are also developed at Dürr. Furthermore, the entire installation management of the tank into the car bodies by means of the manipulator technology is part of Dürr’s supply scope. Dürr also teaches and programs the HRC robot.

High safety standard

Even though there are no fences or enclosures, the safety requirements for human-robot collaborations are significantly higher in comparison to separate robot cells. The safety concept must fulfill strict specifications and standards that are based on a risk evaluation. The safety package calls for, among other things, positioning the robot so that danger of contact with the human is minimized as much as possible. However, human movements also have to be taken into account – and they are not always predictable. Depending on the situation, humans act differently, spontaneously and arbitrarily. Therefore, the robot must act very considerately and switch off within milliseconds of contact being registered.

Dürr has designed the concept for the gluing cell in such a way that the robot principally works underneath the human’s head and chest area. The application technology and the robot itself are also designed to be light, large and rounded, so that when the robot is contacted there are only low forces.

High potential

HRC systems are principally interesting when consistently high qualities are demanded, such as with gluing. The new type of robot cells also have a high potential if humans can be unburdened during physical activities and sustainable effects for reducing the production costs can be achieved at the same time.