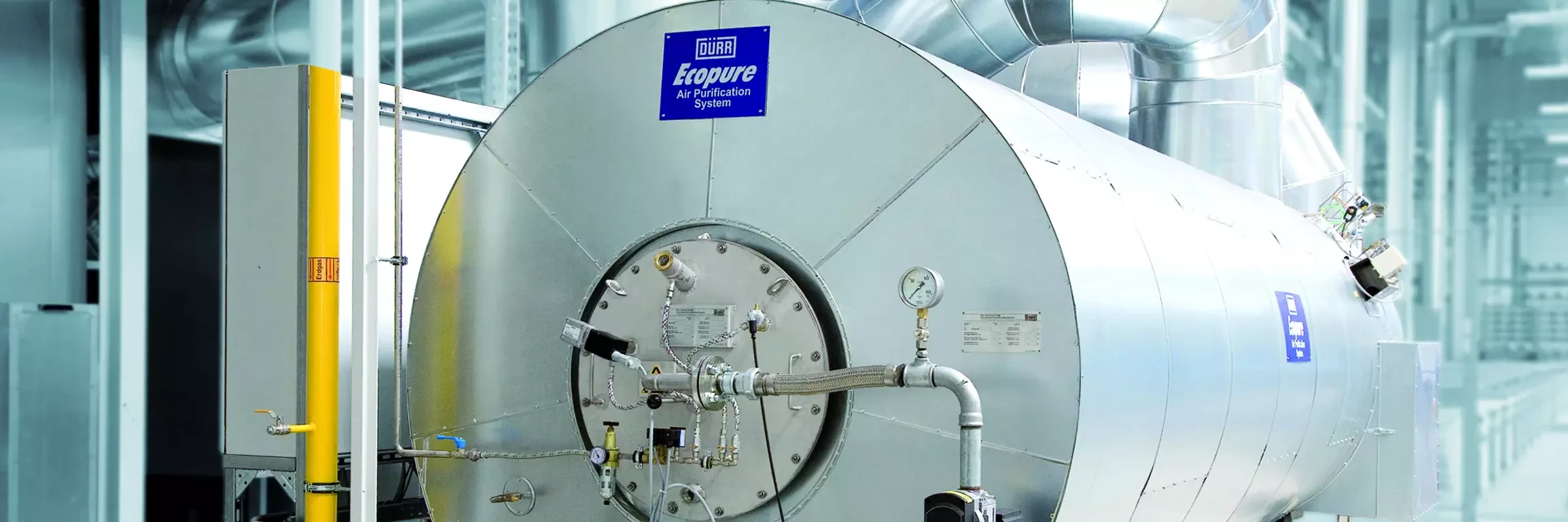

Painting and drying of car bodies produce gaseous pollutants that have to be removed from the air depending on the paint system and statutory requirements. Recuperative incinerators, e.g. the Ecopure®TAR from Dürr, are best suited for cleaning exhaust air flows from dryers because the heat energy contained in the clean gas can be reused in the drying process.

The Ecopure® TAR recuperative oxidizer is also used for cleaning exhaust air from paint spray booths. The painting process produces particularly large exhaust air volume flows that have only low pollutant loads. For this reason, a system for concentrating the solvent-laden exhaust air flows, the Ecopure® KPR concentrator system specifically is ideally installed between the paint spray booth and exhaust air purification system. The exhaust air volume flow is reduced significantly for the following thermal exhaust air purification process. The resulting increase in the pollutant concentration significantly decreases the gas consumption because the energy contained in the pollutants makes a contribution during oxidation.

As in all thermal processes, the exhaust air is heated in the Ecopure® TAR enough to oxidize the hydrocarbons to produce mainly water vapor and carbon dioxide. The polluted air is first preheated by the hot air in the integrated (recuperative) heat exchanger. This allows a large portion of the combustion heat to be recovered. When the air enters the combustion chamber, the burner heats it further and initiates oxidation of the pollutants, which is completed after they have passed through the chamber.

With the Ecopure® TAR, special emphasis must be given to the controllable POWERFLEX heat exchanger from Dürr. The outlet temperature of the purified exhaust air can be controlled independently of the combustion chamber temperature. Due to the variable operating point of the oxidizer, the outlet temperature of the TAR can, for example, be reduced to save energy – without having a negative effect on the clean air quality!

Features such as the innovative reaction chamber design, the more effective air flow and the improved TARCOM burner technology from Dürr offer further added value. Other features include better heat insulation and the optimally integrated heat recuperation for dryer heating.

The Ecopure® TAR saves significant fuel energy and operating costs, achieves better emission levels, and produces a longer system service life thanks to lower combustion chamber temperatures.

An increasing number of automotive paint shops are working with the innovative dry separation system EcoDryScrubber from Dürr, which binds excess paint particles in dry filters – i.e. without water contact. This system not only reduces the energy consumption of the paint shop by up to 30%, but also offers advantages in exhaust air purification. The reason for this is exhaust air from the EcoDryScrubber is highly concentrated and efficiently filtered. This permits a very compact design for the Ecopure® KPR VOC concentration system and the connected TAR recuperative oxidizer, which are used for exhaust air purification. Furthermore, the exhaust air purification systems can be operated very economically. The reason is they require very little energy, because the pollutants themselves supply sufficient fuel energy for operation. For Dürr customers, this means lower investment costs and around 80% less energy consumption. Dürr optimized the Ecopure® KPR so that it can be ideally combined with the EcoDryScrubber paint spray booths.