The more advanced version of EcoScreen has been available since the beginning of 2015 and now offers further new features that take the application a major step forward, especially when it comes to user-friendliness. To this end, fewer fault messages are displayed on screen by listing only the originating fault, highlighted with a red perimeter, and no longer the resulting chain of faults. This allows the system operator to determine the fault in question more easily, as the originating source no longer needs to be searched for on the screen amongst all the subsequent faults. Possible causes of the fault are also displayed for every fault recorded as well as appropriate troubleshooting steps to be taken. In the process, messages are organized separately in detail windows for each robot, whereas in the previous version, the messages were provided unfiltered in one single list.

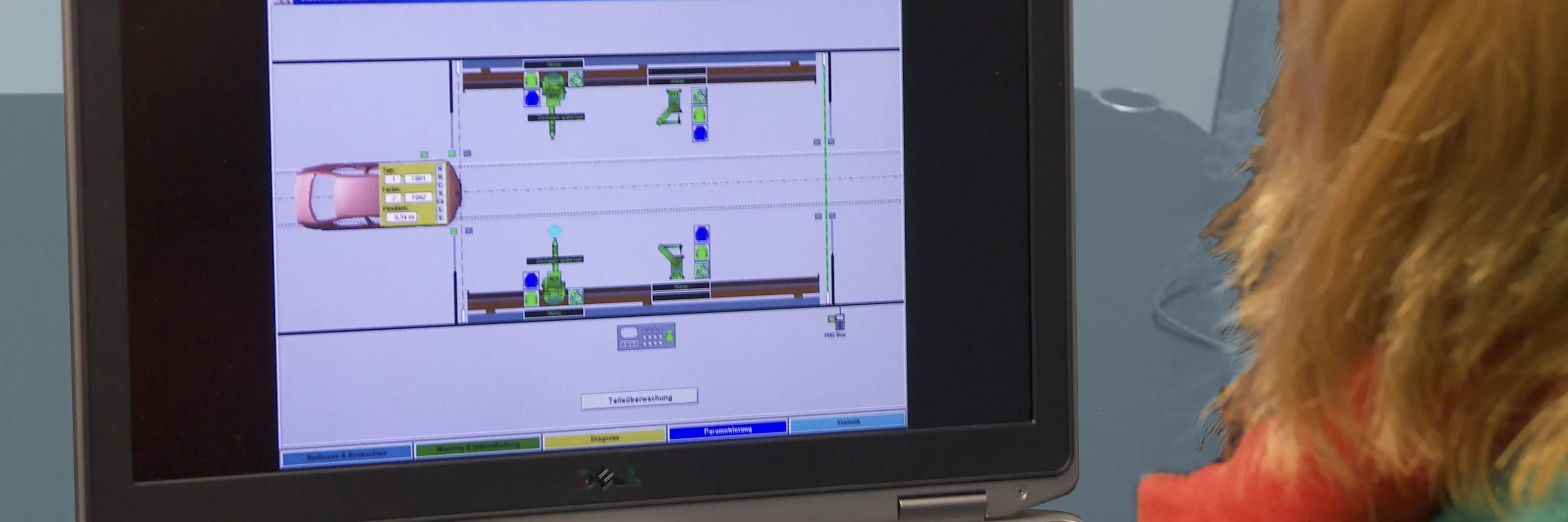

For the first time, EcoScreen also offers graphical diagnostics for the conveyor system interface to delineate operating states of the conveyor system. The software enables this in a simplified format that can also be understood by non-specialists. This type of diagnostics is used whenever the system operates in automatic mode and the conveyor with the vehicle bodies has stopped moving. The reason for this typically relates to a general problem such as someone entering the station during the painting process or a robot malfunctioning. To quickly and efficiently resolve the problem, the current state of the system is displayed along with appropriate measures.

The new and intuitive user guidance facility also provides the system operator with step-by-step instructions when carrying out specific actions such as starting time programs or fixed position travel runs, and notes tell the operator what measures to implement or why certain actions cannot be carried out at the moment. Employees with minimal previous experience are thus equally as well suited to operating the system reliably as their more experienced co-workers.

The new version of EcoScreen has been integrated in all new Dürr painting booths since the beginning of 2015.