So far, the two CHP units have produced 8.3 million kilowatt-hours of electricity per year, providing power to around 7,100 end-users. The heat produced in the process is used to heat the municipal utility company’s buildings and those of neighboring companies. Additionally, the fermenter and post-fermenter are also heated. The temperatures are maintained at a constant level of 40 degrees Celsius (40ºC) to ensure ideal living conditions for the microbes responsible for the fermentation and outgassing processes. During the summer, the heat is also used to dry herbs in a neighboring agricultural operation. “The concept thus corresponds to the fundamental idea of combined heat and power (CHP), according to which the energy is simultaneously converted to electrical power and heat and used,” says GGV managing director Paul Weber.

Dürr ORC technology

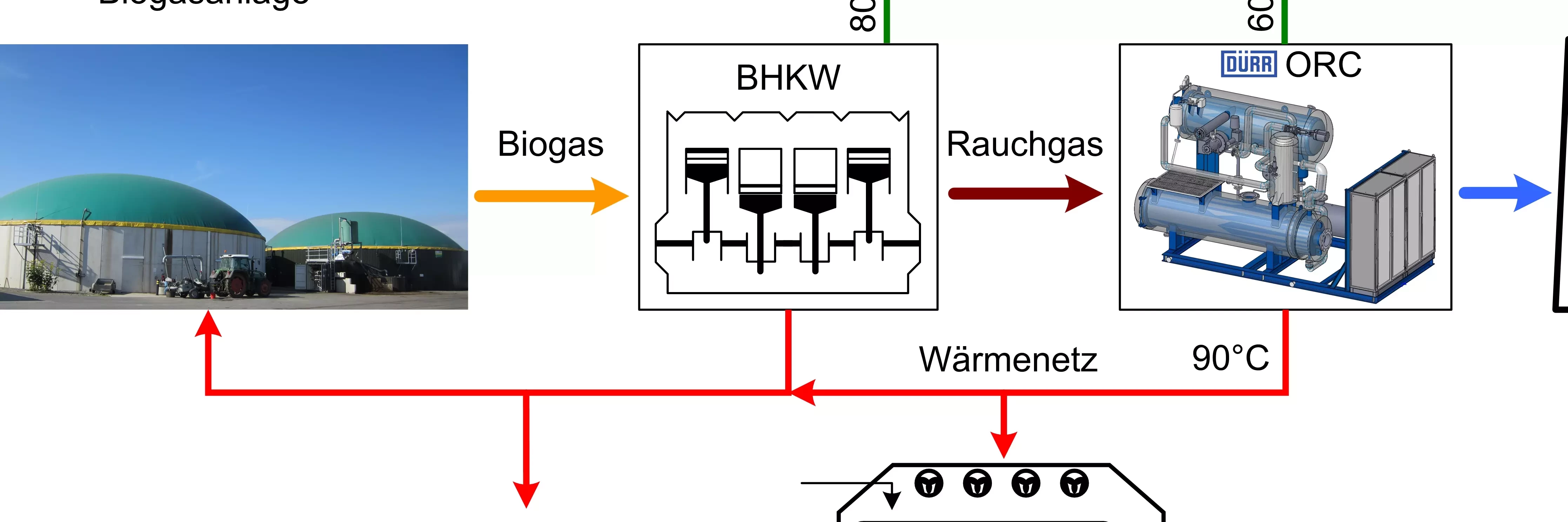

The integration of the ORC system from Dürr, the system construction specialist, enhances comprehensive energy utilization. ORC stands for “Organic Rankine Cycle” – a procedure that uses waste heat to produce electricity with the aid of an evaporation process. In Groß-Gerau, the high-temperature flue gas waste heat from a CHP unit with an electrical output of 800 kWel is used for this purpose. “This proven principle produces 60 kWel of additional power on average,” explains Dürr project leader Timm Greschner. “No heat is lost in the process, no matter whether or not a concept for heat utilization exists. Up to 18% of the total heat in the flue gas is converted to electricity, and the remaining (approx. 82%) is provided at a temperature level of up to 90ºC.” A significant efficiency increase in power generation has therefore been realized in Groß-Gerau without restricting the existing heat utilization concept.

The ORC system is simple and robust and easily integrated into the overall system. Since there is no complex intermediate circuit and no separate turbine lubrication with lubricating oil, the system also operates very stably. The ORC system uses the flue-gas heat throughout the year and also produces full power in the summer thanks to the high condensation level.

Economic efficiency

This investment has been worthwhile for the Stadtwerke Groß-Gerau municipal utility company. The integration of the ORC system permitted the exhaust-air heat exchanger behind the CHP unit to be omitted. The total electrical power generated is increased from 8.3 to more than 8.7 million kWh. This allows electricity to be provided to around 360 more end-users. Despite the omission of the exhaust-air heat exchanger, the heat is fed into the heating network and is fully available for herb drying and for heating the administration building, the fermenter, and the post-fermenter.

The amortization period of such an ORC investment is five years with an electricity buyback price of 20.3 cents/kWh and 7,500 hours of full utilization. With a depreciation period of ten years, this corresponds to an internal rate of return of 15.6%

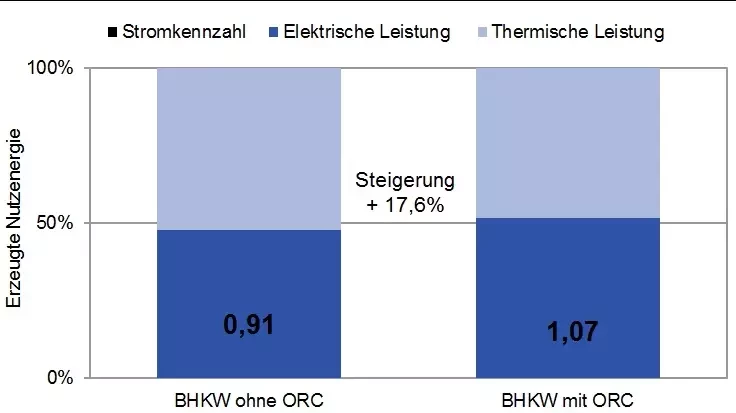

The use of ORC technology perceptibly increases the CHP remuneration. According to the recommendation from the clearing office for the German Renewable Energy Law dated November 25th, 2010, “Systems with heat extraction (…) are to be considered as a unit for the purpose of determining the power to heat ratio if a device is used to convert the extracted heat into electricity by means of an additional generator.” Consequently, the power to heat ratio of the overall system consisting of CHP unit and ORC improves according to the formula below:

Power to heat ratio:

The CHP remuneration results from the sum of the externally used heat multiplied by the power to heat ratio and by the CHP bonus. This means that the remuneration automatically rises when the power to heat ratio is increased by the ORC system.

With unchanging heat utilization, the CHP income increases by 17.6% with a retrofitted CHP unit. In the case of heat utilization with a dryer (e.g. a wood, digestate, or herb dryer) of 1.5 million kWh/a, the resulting additional CHP income is around € 7,100 per year.

Other applications

“Beyond the use in CHP concepts, ORC systems from Dürr are suitable for a broad range of applications. The energy-efficient technology from Dürr generally can be coupled with the most diverse combustion engines and waste-heat sources. Waste heat is one of the largest unused potential sources of energy in Germany,” explains Frank Eckert, Managing Director of Dürr Cyplan. “Waste heat from industry, firing systems, and the use of geothermal heat sources are especially attractive application options for ORC technology, which assists in developing energy-efficiency potentials as well as attractive returns on capital.”