Within the Dürr Group the Italian subsidiaries Olpidürr and Verind act as a center of excellence for aluminum wheel paint shops providing systems integration and high-end application equipment. Recently, they executed two projects for the wheel manufacturer Ronal’s production of diamond-cut wheels. High-sheen and front-polished, diamond-cut finished alloy wheels are very popular and demand a special process.

Dürr supplied such a paint line for the finishing of diamond-cut wheels in Ronal’s Querétaro Mexico facility. Dürr Mexico, also based in Querétaro, played an important role in the project, especially in terms of local supply and installation, and will be on site for future service assistance. Supported by the worldwide network of the Dürr Group – whose expertise includes dedicated and customized planning of all crafts and process interfaces as well as efficient project management – the Italian subsidiary Olpidürr oversaw the successful implementation: The paint line in Mexico was commissioned in 2016.

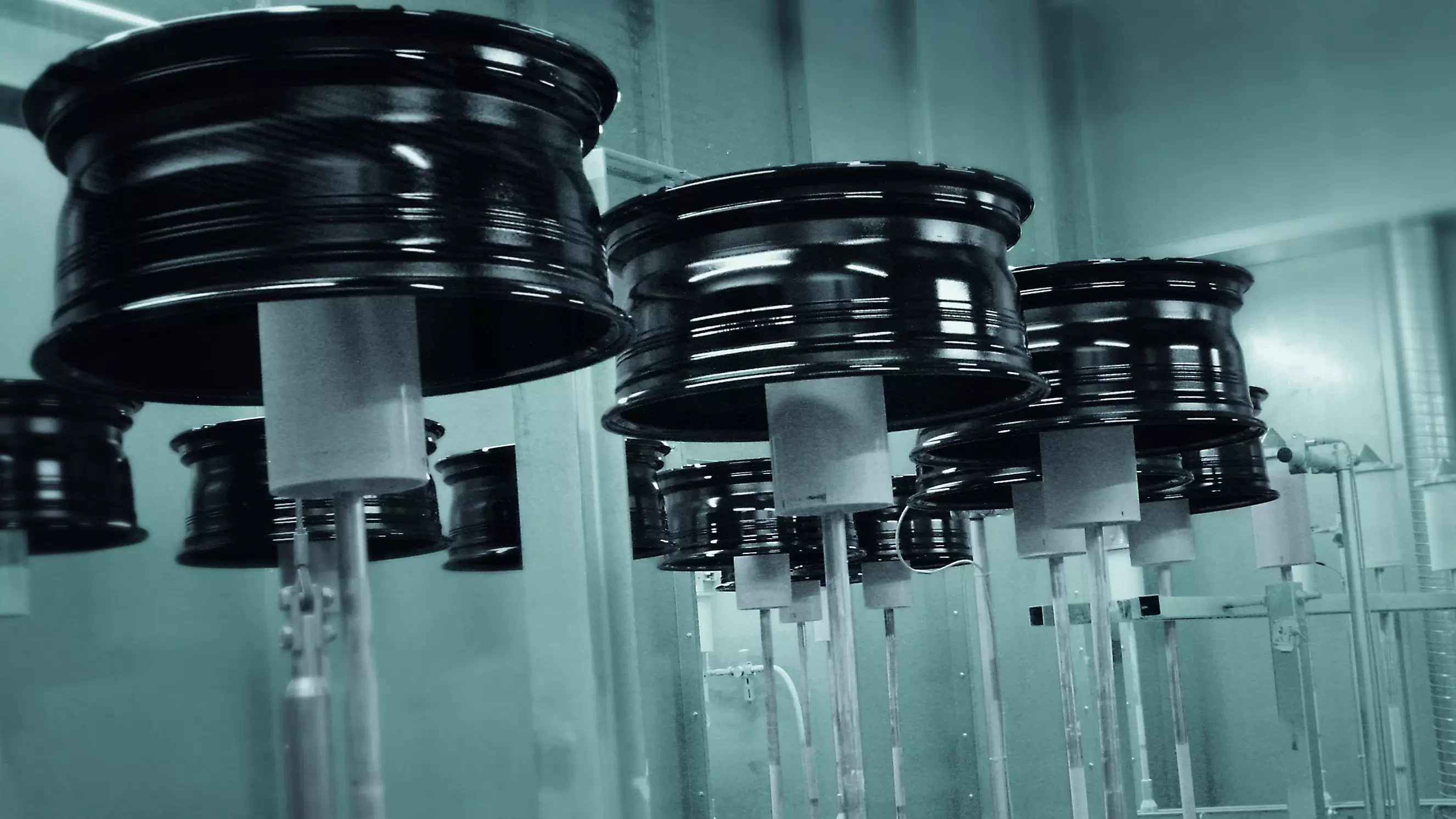

In 2016 Ronal partnered with Dürr for a new paint shop at their site in Jičín, Czech Republic. Dürr again employed the split-line design, as this configuration optimizes the production process by avoiding second runs on the same line. Both painting lines are completely housed, to avoid indoor pollution of the production hall. This design was also used in the Mexico project. Olpidürr was acting as a systems integrator. Verind was the paint application equipment specialist, contributing automatic wet paint application systems including the paint mix room as well as circulating and spray equipment. The painting lines are capable of processing both solvent-borne and waterborne paints with a ratio of “0÷100%”, thus meeting state-of-the-art requirements requested by the customer.

In addition to leading edge technologies and devices for wheel painting lines the Dürr concept for the Ronal paint shops in Querétaro and Jičín contained a variety of unique solutions focusing on energy savings throughout the plant.

In the Ronal aluminum wheel painting lines, wheels are transferred in a system of independent synchronized conveyor loops by manipulation robots provided with special grippers. To keep the production process running smoothly, in-house team of Dürr IT specialists developed supervision software for Ronal. Its’ use makes the production process extremely safe, manageable and allows for remote troubleshooting and modifications during the entire life-cycle of the paint line.

The site opening in Jičín was in January 2017 while SOP is scheduled for April 2018.