RoDip® M – Mechanically driven dip coating with an efficient chain drive

The RoDip® rotational painting system stands for the perfect interplay between plant and conveyor, and ensures efficient transport solutions for car bodies through treatment lines.

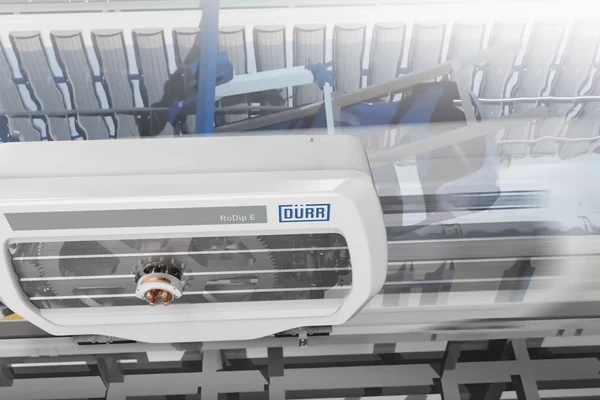

RoDip® M, the mechanical version of our rotational dip coating system, is robust and continuous. The system has a chain hoist on each side of the dip tanks, which pulls the RoDip® carrier and body through the process line together. A lateral V-cam provides 360° movement. Generally, both linear and rotary movement are feasible. RoDip® M is a highly reliable, sturdy, user-friendly system.

RoDip® M at a glance

- Chain drive on both sides

- Rotation by v-cams

- Linear or rotary movement

- Horizontal return lines beneath the tanks

- Recommended production rate >40 u/h

- Continuous operation

New features

- One-sided guidance reduces complexity for more efficiency and optimized maintenance work

- Multiple angled V-guides reduce turning speed in critical areas and result in lower forces on the hood for gentle emersion

- Optional: flexible guide track for body related drainage

- Integrated carrier-cleaning during non-productive time

- Tiltable conveyor for longer draining times