Test center PT/ED

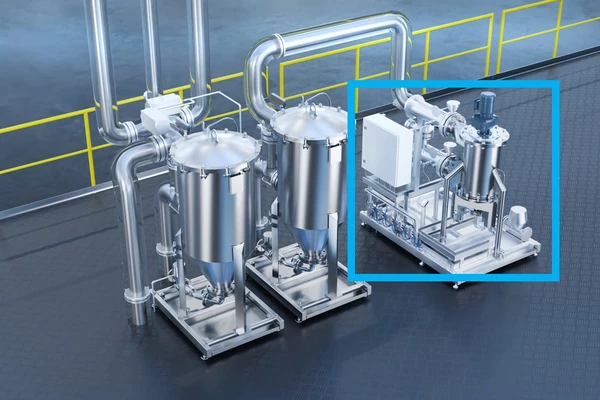

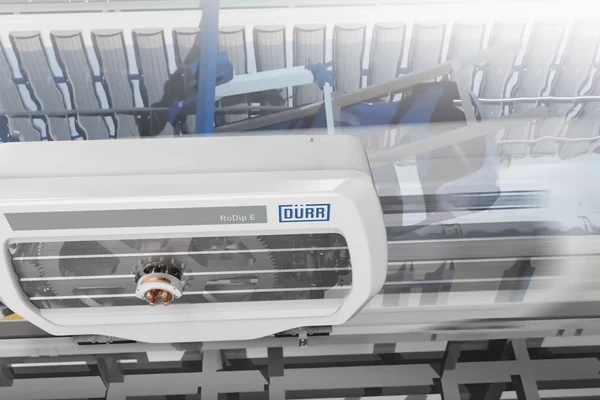

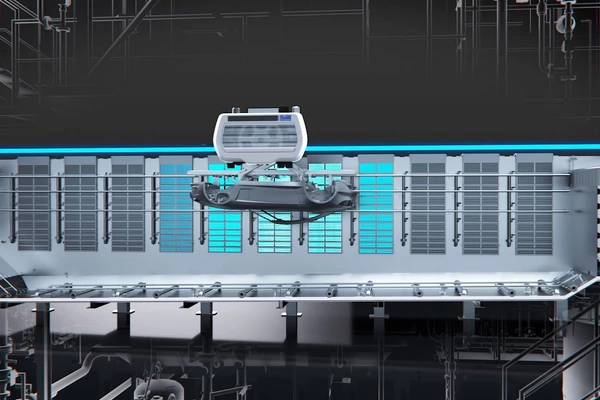

Over 25 million vehicles have already been painted worldwide with the rotating dip-coating system RoDip®. Dürr is continuously improving this technology. In the Test center PT/ED, such topics as improved draining characteristics are worked on. With the test setup for the EcoMultiCyclone the already very efficient filtration system for bath maintenance in the rinsing and degreasing zones of the pretreatment is continuously improved.

Saving potentials with pretreatment

Savings potential starts with the pretreatment. By means of the RoDip® Test Facility, this rotational dip process was developed over several product generations with respect to immersion, flooding and draining. And even today, after more than 25 million cars have been coated using RoDip®, Dürr is continuing its work on areas of potential improvement.

Our service portfolio

- Dipping experiments to test chassis rigidity (chassis stress test)

- Tests for specific draining properties for various car bodies

- Dipping skid experiments

- Validation of new products and procedures for maximum system availability

- Cycle time studies

- Testing of new controls programs

- Examination of interfaces to other system components