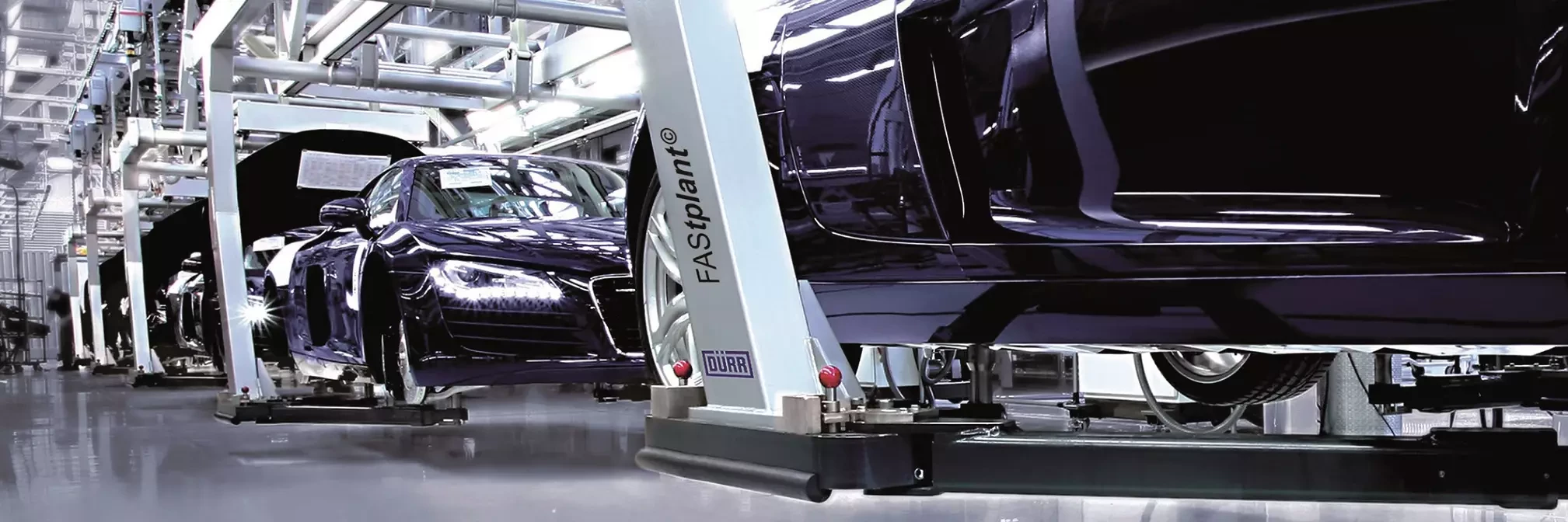

FAStplant® – The modular Final Assembly System

Dürr represents worldwide success and stands for technological leadership in the field of final assembly.

FAStplant® is a modular system for final assembly. It makes production line design flexible by combining different components. The modules require neither ceiling suspensions nor foundation pits, which eliminates building constraints. FAStplant® is ideal for pilot lines as well as SKD (semi-knocked down) and CKD (completely knocked down) installations.

FAStplant® modules

- Electric Monorail Systems with self-supporting modular structural steelwork for work zones and return section, as well as curves and track switches

- Skillet Platform Systems with and without integrated lifting table with platform height of < 300 mm

- Modular man-rider conveyors

- Utility Structural Steelwork for module pre-assembly

FAStplant® benefits

- Flexible plant line extension, shortening or relocation

- Easy adaptation to new vehicle models or variants

- 30% shorter installation time thanks to pre-tested and pre-assembled modules

- Line setup free of building constraints

- Less effort in terms of planning and engineering

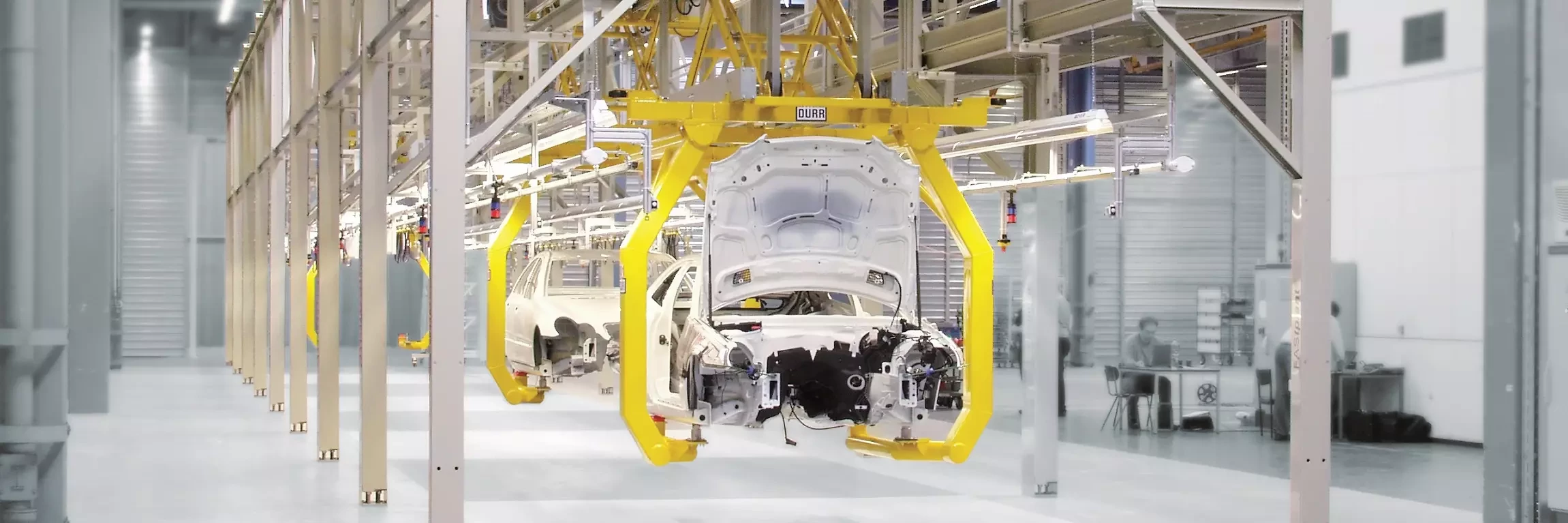

FAStplant® as a pilot line

All the performances of a big final assembly system in a miniature assembly shop.

One of the applications of FAStplant® is certainly as a pilot line in a dedicated room of the final assembly shop.

FAStplant® as a pilot line can be used as a:

Traning center

All operations of the final assembly shop are simulated and new workers learn in advance how to manage

- VAC Line

- Subassembly Line

- Manual Marriage Line

- Trim Line

- Final Line

- Car delivery station

Center of ergonomics studies

A bar code along the carrier arm defines the best rotating angle to reach the highest ergonomics possible for every operation.

Miniature final assembly shop

With a Twin Trolley System® as a conveyor and with a high-precision vertical adjustable and rotating carrier on board.

Every Training Center / Pilot has a FAStplant® structure 12m high.