Noticias

Aquí encontrará toda la información sobre proyectos actuales de clientes, productos nuevos, eventos y otras notas de prensa de Dürr. Si tiene preguntas sobre publicaciones o necesita más información, no dude en ponerse en contacto con nosotros.

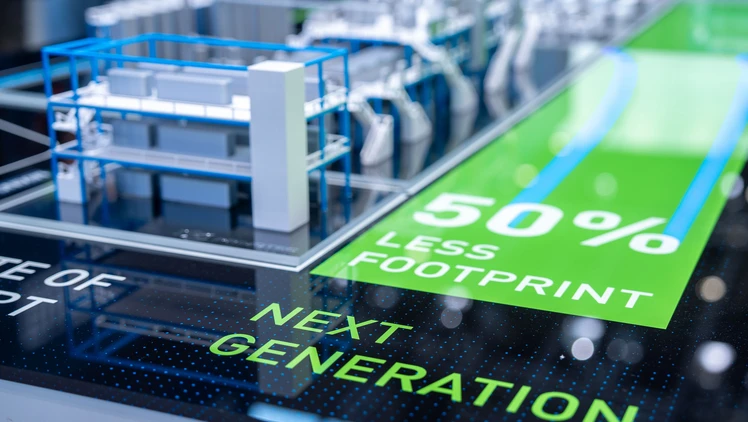

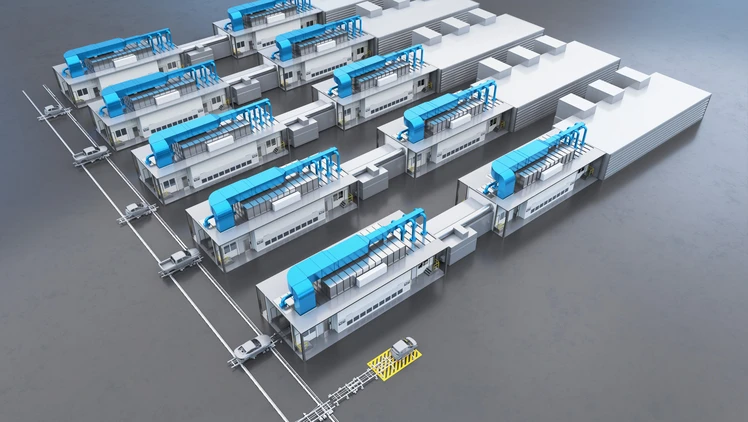

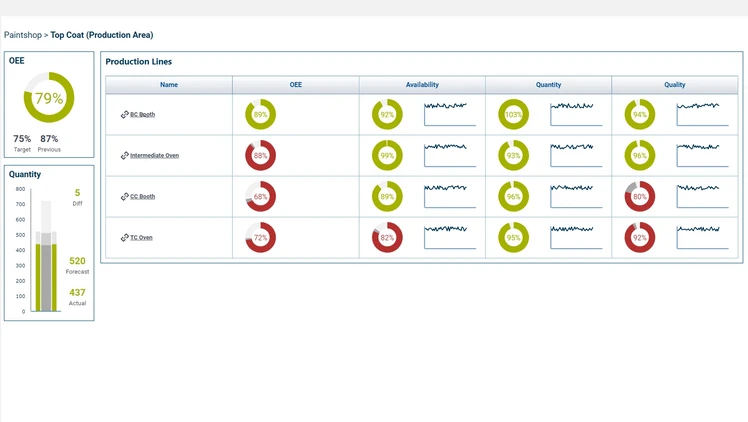

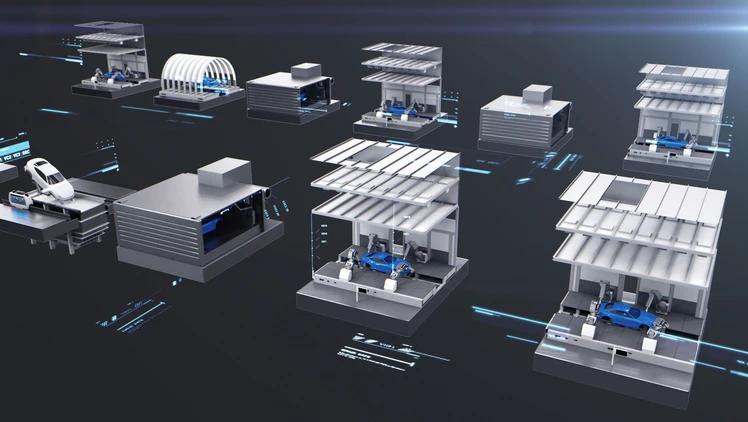

El Grupo Dürr es una de las empresas de ingeniería líderes en máquinas e instalaciones a nivel mundial con destacada experiencia en automatización, digitalización y eficiencia energética. Sus productos, sistemas y servicios permiten procesos de manufactura altamente eficientes y principalmente para la industria automotriz, fabricantes de muebles y construcciones de madera, así como también para la industria química, farmacéutica, dispositivos médicos, ingeniería eléctrica y la fabricación de baterías. En 2024 generó ingresos por ventas de 4,700 millones de euros. El Grupo Dürr tiene más de 18,400 empleados y 139 instalaciones en 33 países. A partir del 1 de enero del 2025, las antiguas divisiones de sistemas de pintura, montaje final y tecnología de aplicación se fusionaron para formar una nueva división llamada Automotive. Por lo que de ahora en adelante, el Grupo Dürr opera en el mercado con cuatro divisiones:

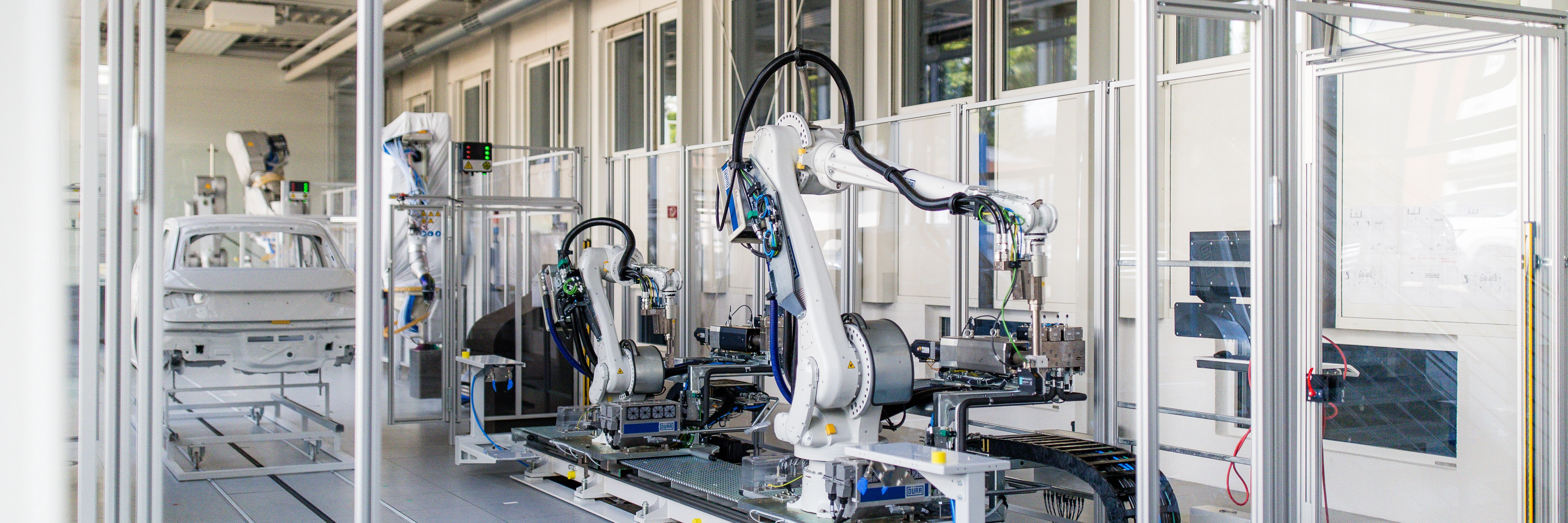

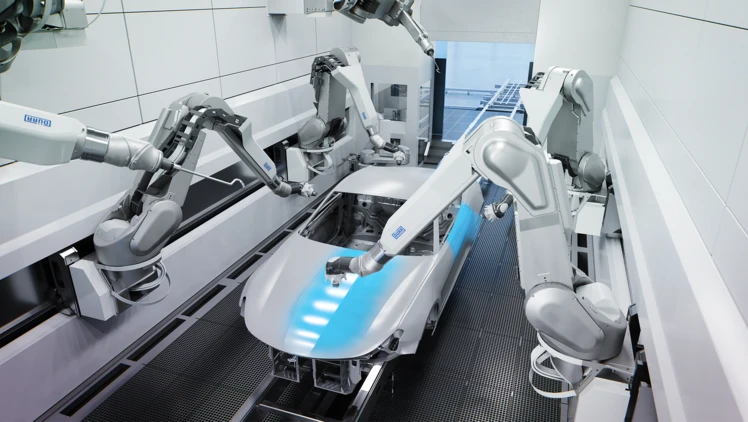

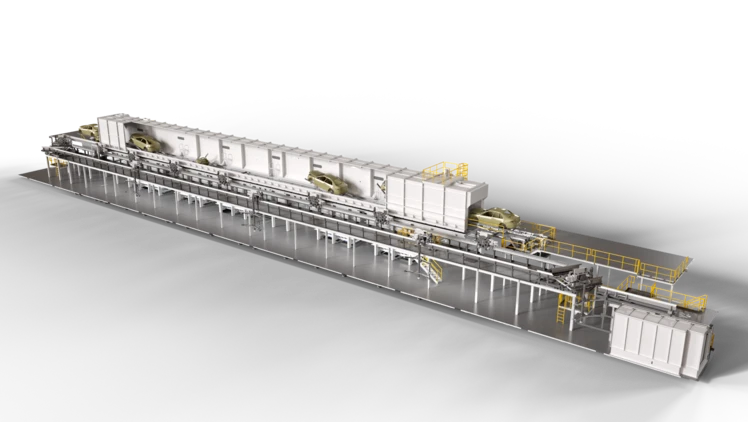

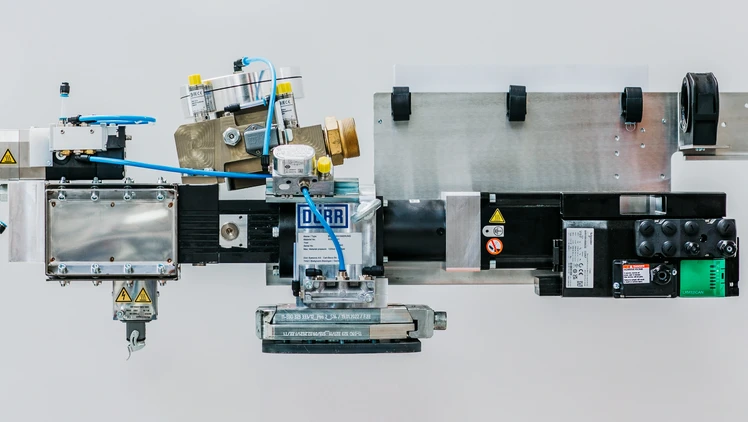

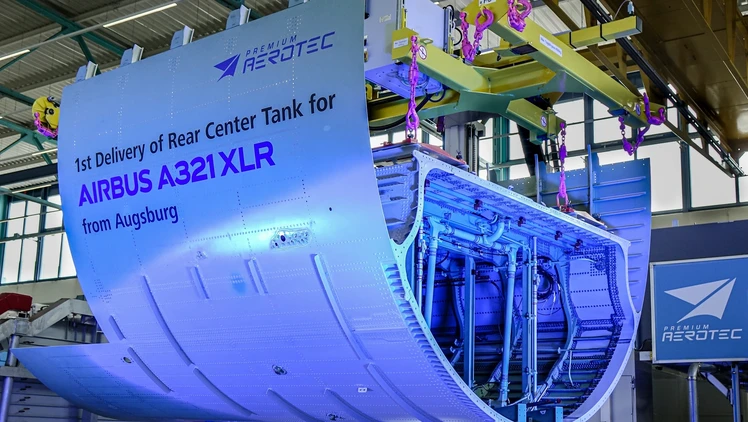

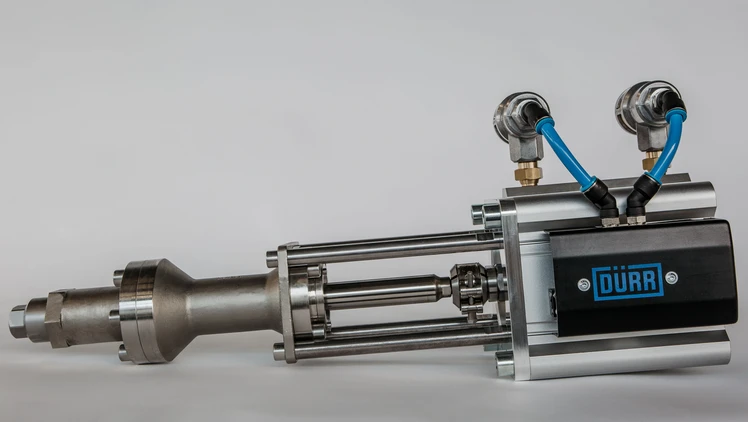

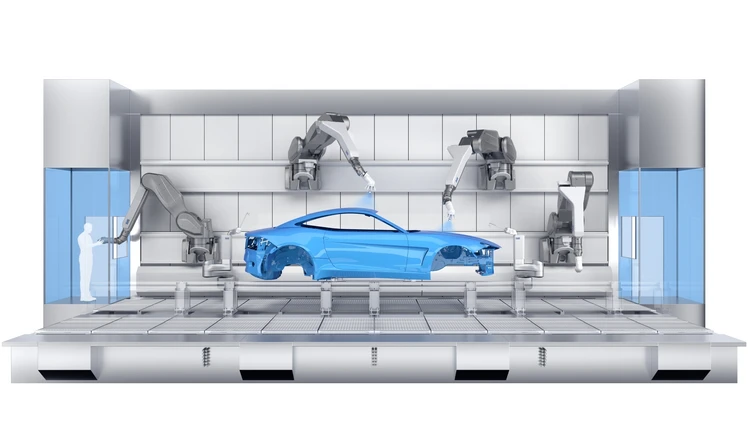

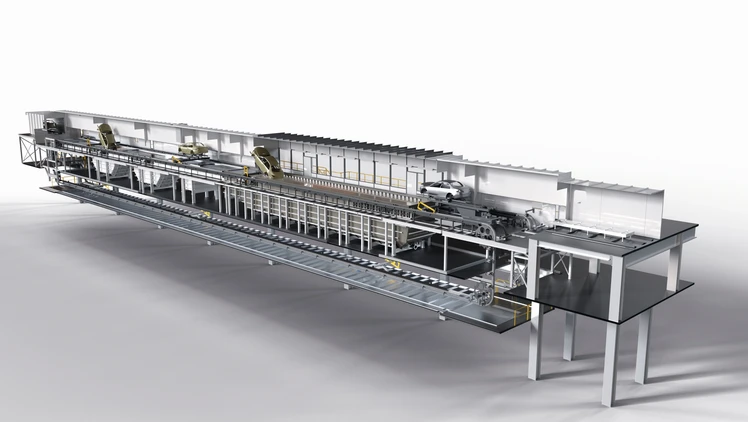

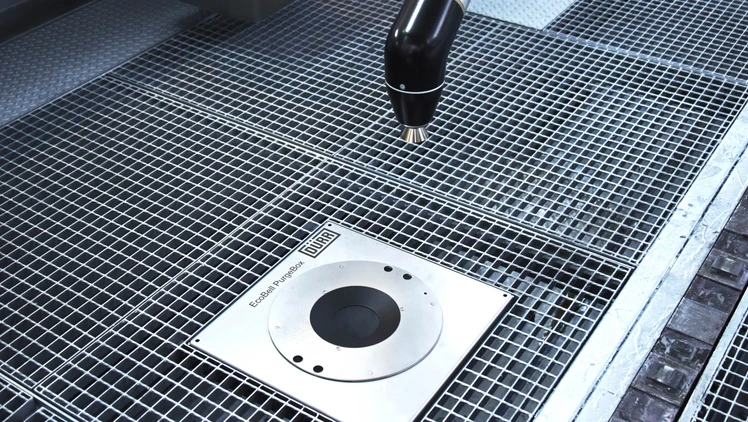

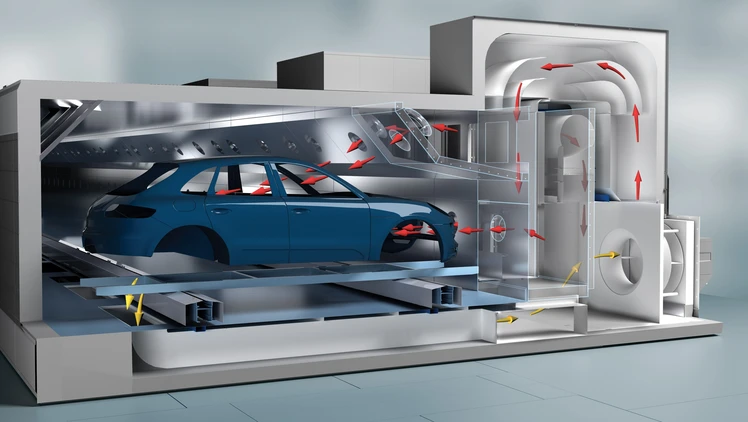

- Automotive: Tecnología para plantas de pintura, así como montaje final, tecnología de pruebas y llenado para la industria automotriz

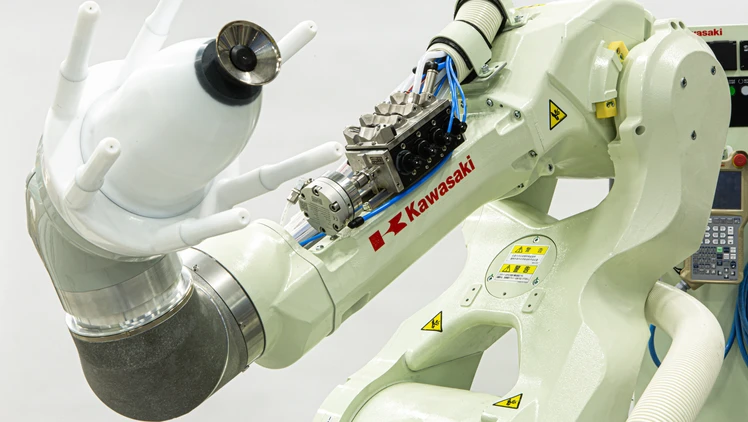

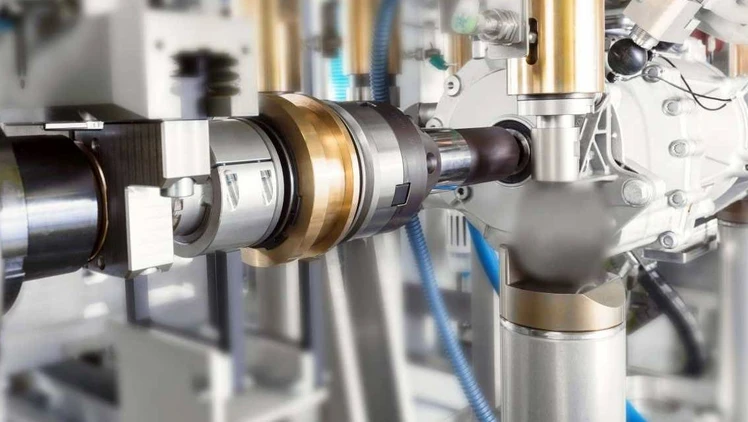

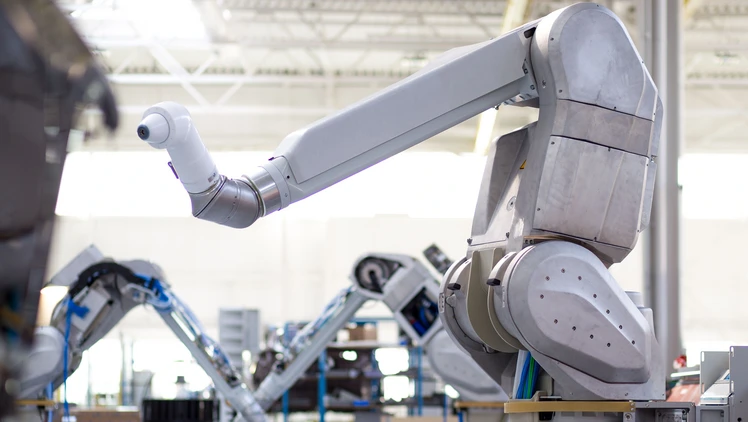

- Industrial Automation: Sistemas automatizados de montaje y pruebas para componentes automotrices, dispositivos médicos y bienes de consumo, así como tecnología de balanceo

- Woodworking: Máquinas y sistemas para la industria de transformación de la madera

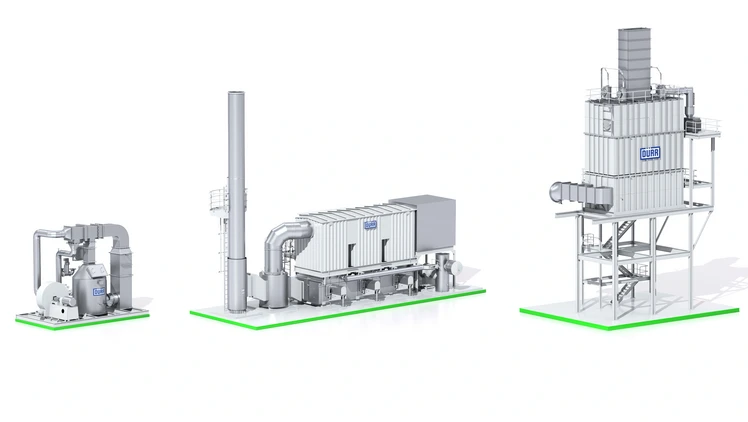

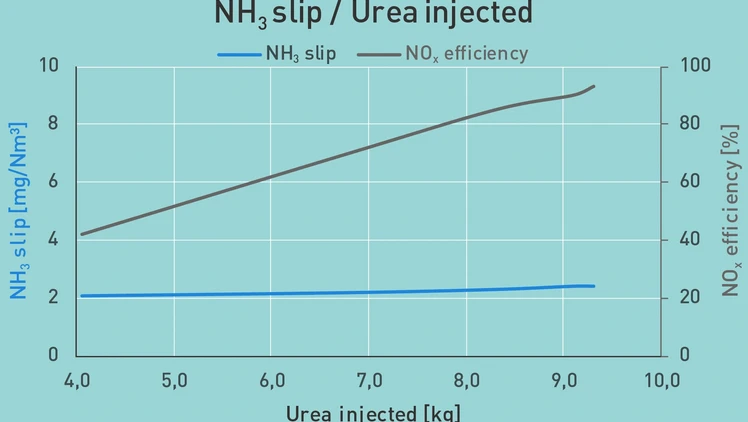

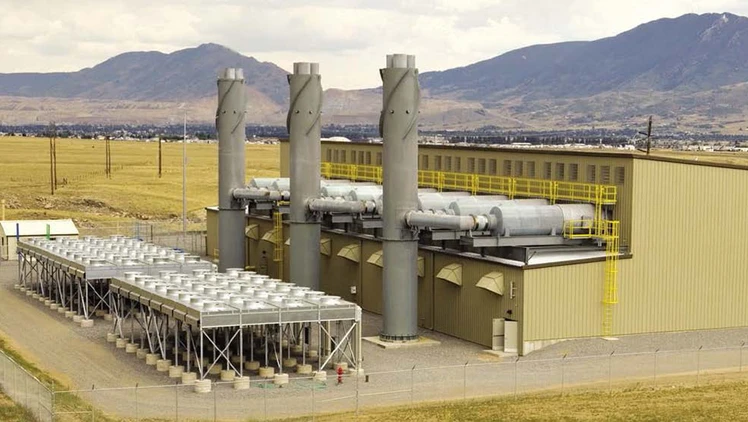

- Clean Technology Systems Environmental: Sistemas de purificación en la extracción del aire, líneas de recubrimiento de baterías y sistemas para reducción de ruido