Notícias

Aqui você encontra todas as informações sobre os projetos de clientes atuais, novos produtos, eventos e outros comunicados à imprensa da Dürr. Se você tiver dúvidas sobre divulgações ou precisar de mais informações, entre em contato conosco.

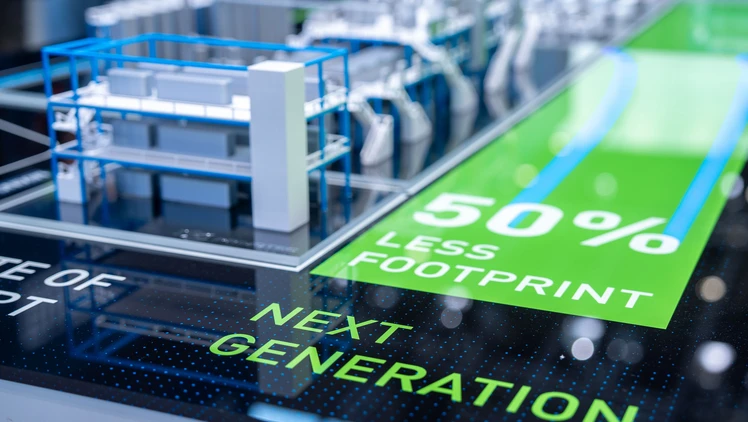

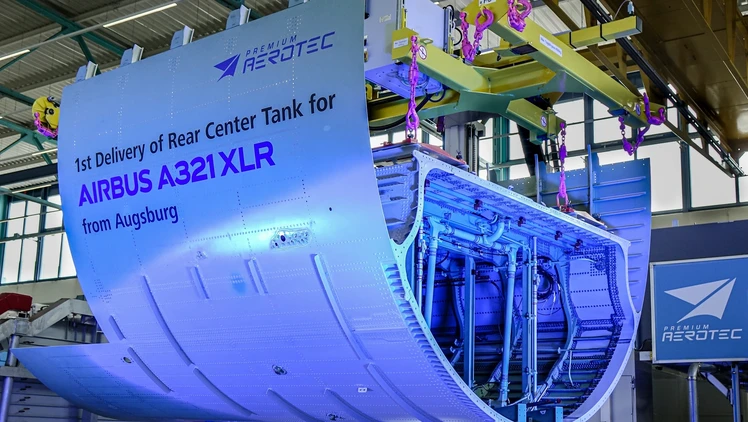

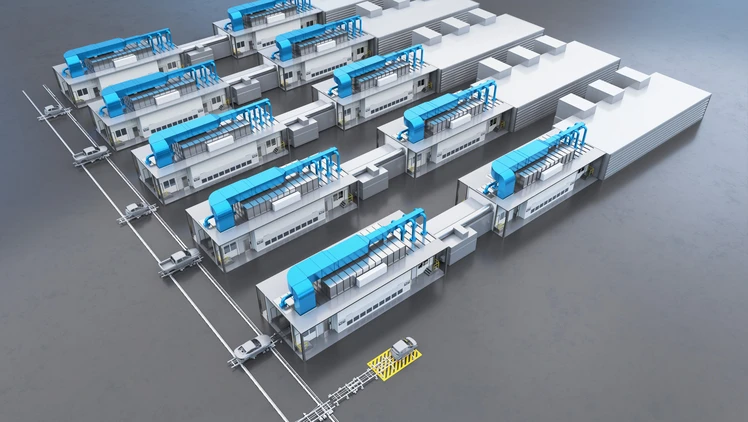

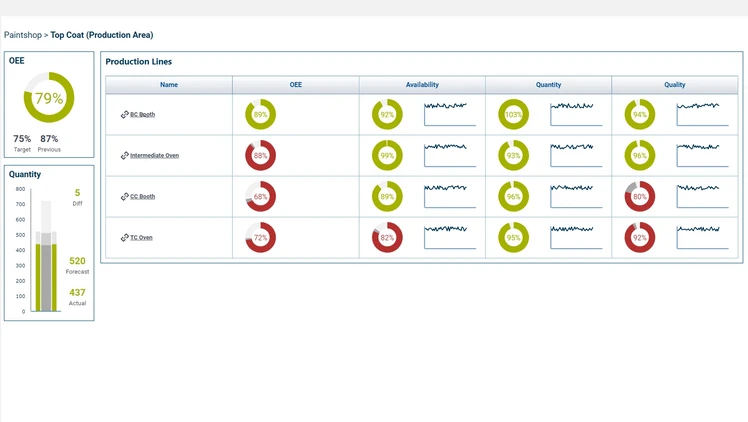

O Grupo Dürr é uma das principais empresas de engenharia mecânica e de instalações do mundo, com expertise nas áreas de tecnologia de automação, digitalização e eficiência energética. Os seus produtos, sistemas e serviços permitem processos de produção altamente eficientes e sustentáveis – principalmente na indústria automotiva e para fabricantes de móveis e casas de madeira, e também em setores como indústrias químicas e farmacêuticas, dispositivos médicos, engenharia elétrica e produção de baterias. Em 2024, a empresa gerou vendas de 4,7 mil milhões de euros. O Grupo Dürr possui mais de 18.400 funcionários e 139 locais de negócios em 33 países. A partir de 1º de janeiro de 2025, as antigas divisões Paint and Final Assembly Systems e Application Technology foram fundidas para formar a nova divisão: Automotive. Desde então, o Grupo Dürr está operando no mercado com quatro divisões:

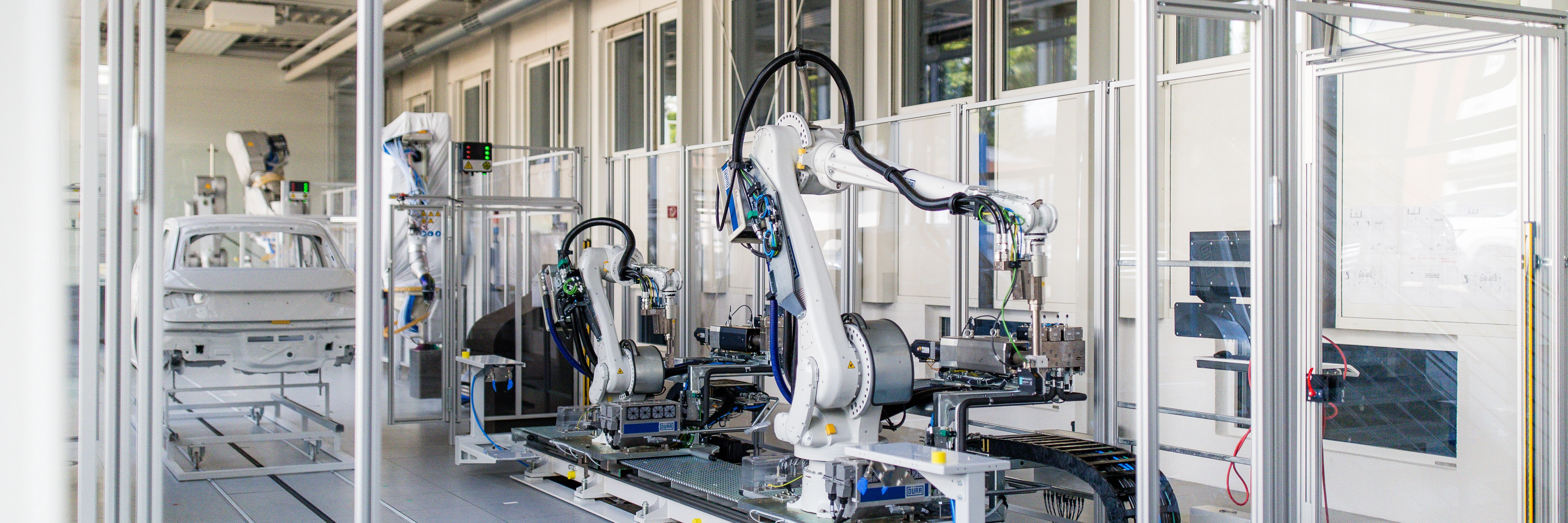

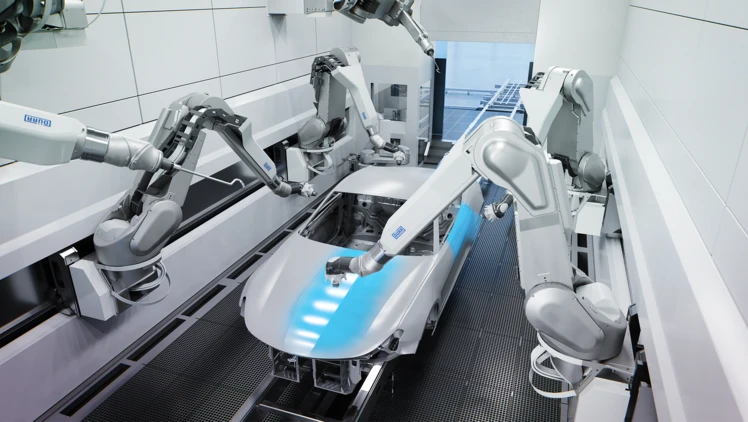

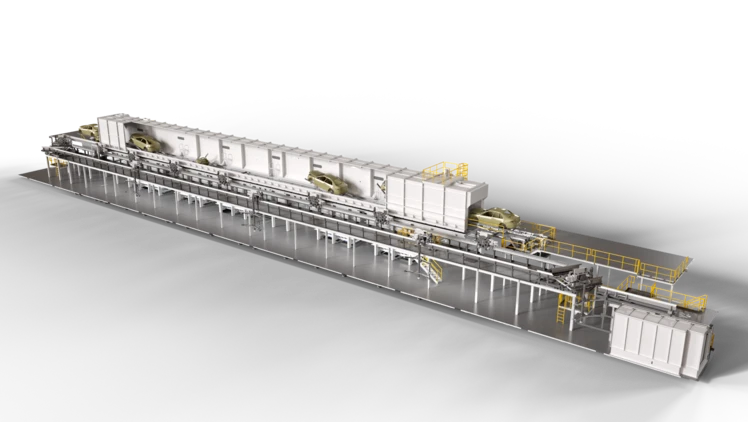

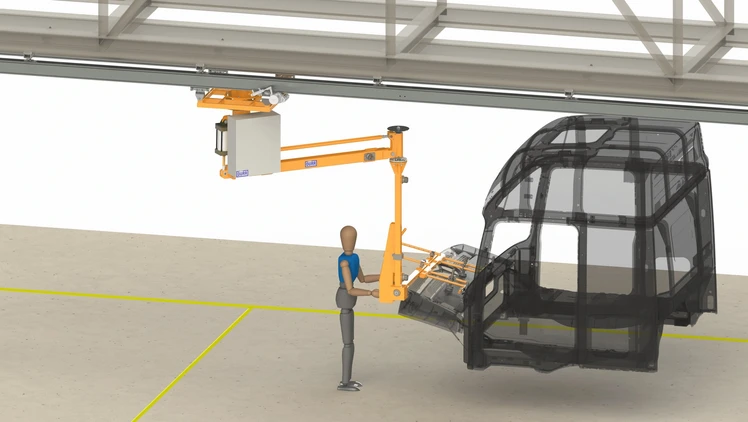

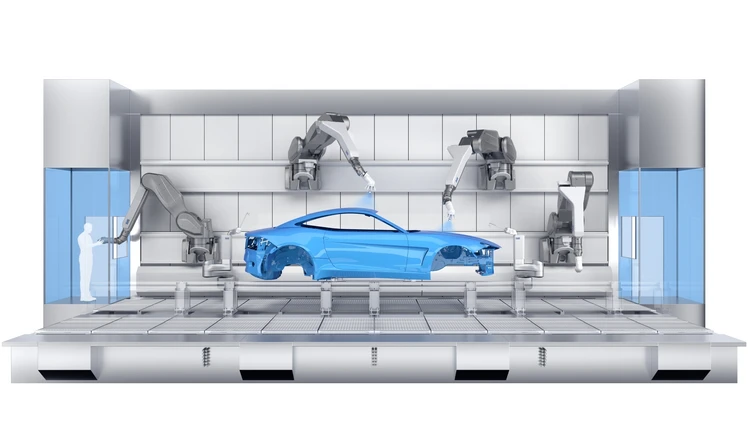

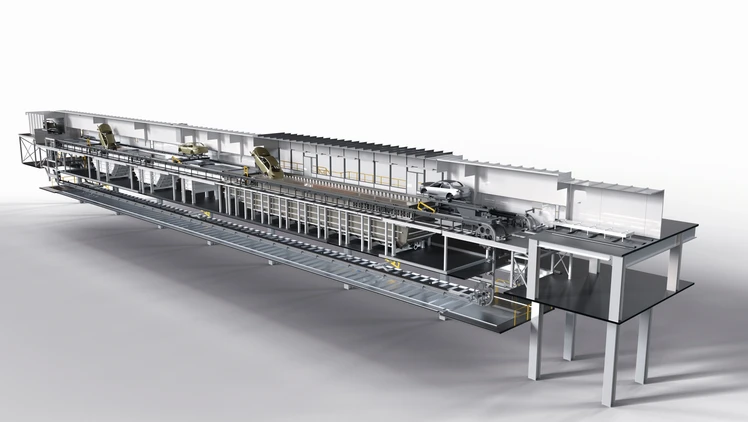

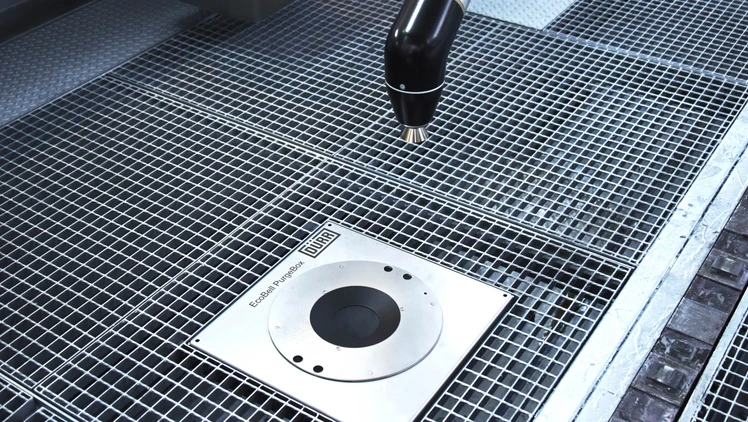

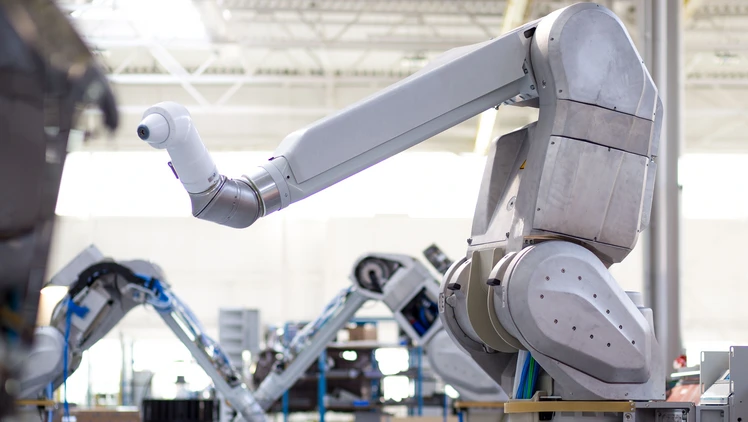

- Automotive: paint shops, bem como montagem final, testes e tecnologia de enchimento.

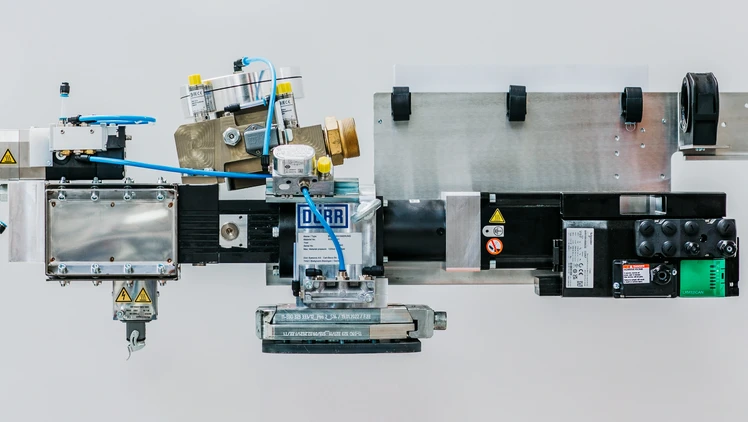

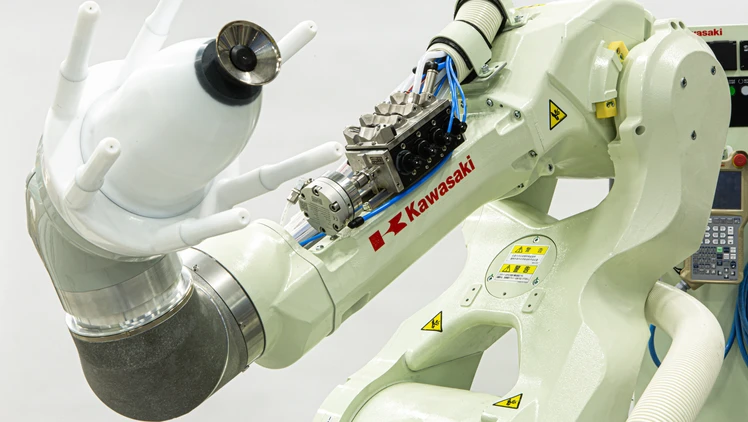

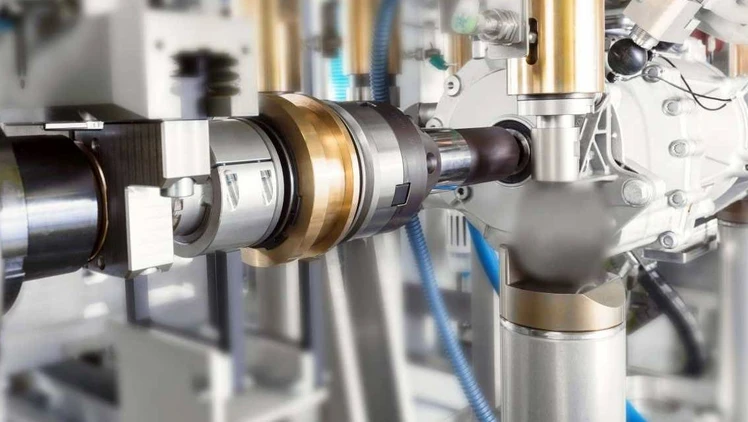

- Industrial Automation: sistemas automatizados de montagem e teste para componentes automotivos, dispositivos médicos e bens de consumo, bem como tecnologia de balanceamento e sistemas de revestimento para eletrodos de bateria

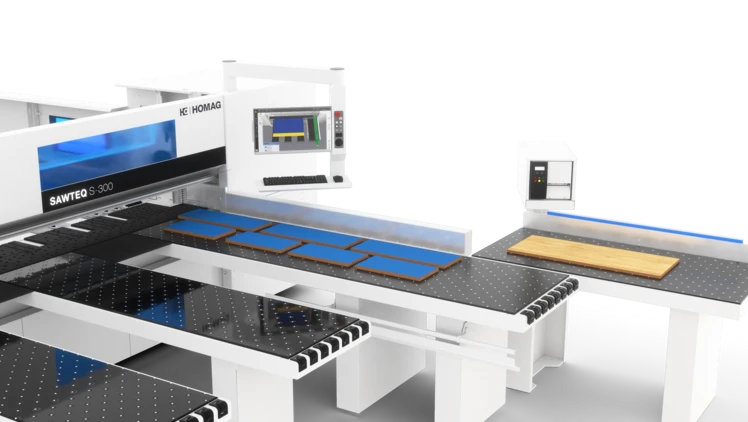

- Woodworking: máquinas e equipamentos para a indústria da madeira

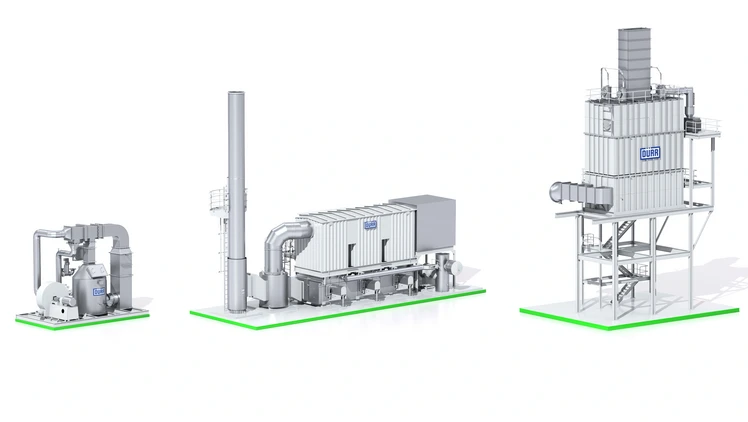

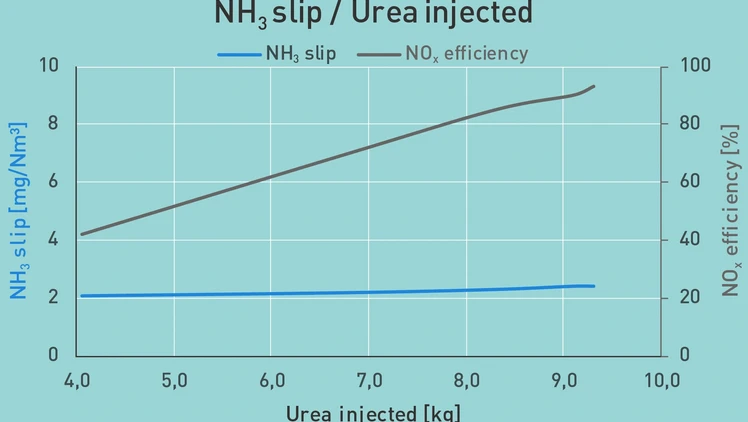

- Clean Technology Systems Environmental: controle de poluição do ar e sistemas de redução de ruído