ADAS cobot expands testing capacity

Mar 18, 2024

A new application featuring collaborative robots (cobots) enhances end-of-line test stand productivity. Dürr’s innovation positions calibration equipment for camera and radar systems with high precision and efficiency, ensuring optimal final assembly line operation for current tasks while equipping it for future challenges. The first ADAS cobots were successfully deployed at Ford Otosan’s site in Inönü, Turkey.

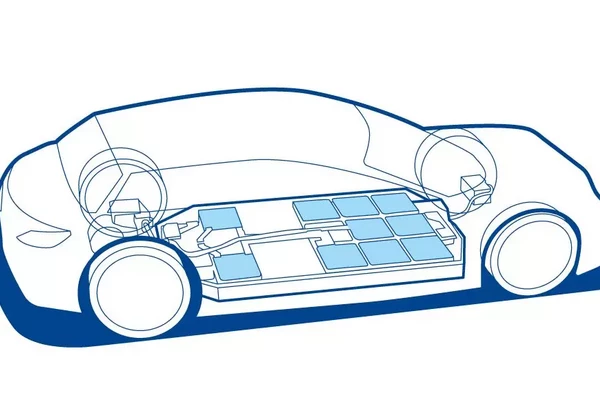

More advanced driver assistance systems (ADAS) are being installed in commercial vehicles and passenger cars to enhance comfort and safety. A legal mandate for commercial vehicle testing (CVT) will require side radar systems for all newly registered trucks and buses in the EU starting in July 2024. All active assistance systems in vehicles are already calibrated today. The calibration devices required for this currently use motorized linear technology and are positioned in the test stands at the end of the line (EOL) in the sensor areas around the vehicles.

The highest precision for ADAS calibration processes with maximum flexibility

The need to calibrate additional systems and sensors at a designated speed, coupled with increasing model and equipment variations, poses a challenge for the vehicle production. In addition, modern ADAS systems, in particular, require maximum precision during the calibration process. It is no longer enough for calibration devices to offer only translatory – in other words, continuously rectilinear – adjustment. The rotatory plane is also needed. The linear technology’s limitations become evident in this context.

Dürr developed a new solution to meet these requirements: a collaborative robot (cobot) that safely and precisely positions the calibration equipment for camera and radar systems. The system easily adapts to new vehicle models with different sensor positions for nearly unlimited flexibility. Its versatility extends to both CVT and passenger vehicle testing (PVT) applications, suitable for new systems and cost-effective retrofitting of existing systems.

Stand-alone test stand optimizes the production process

Correct sensor calibration requires a flat, level floor surface, something not found on every shop floor. To address this challenge, Dürr developed an automatic tilt correction system that the cobot uses to offset floor unevenness during calibration processes. The x-3Dsurface chassis measurement system calculates the values for the target robot position. This contactless measurement technology features precise 3D measurement.

ADAS cobots offer versatile integration options tailored to customer needs. For example, the system integrates with x-wheel truck d wheel alignment stands. This saves lots of space at vehicle sensors that need lateral calibration since the robot systems are mounted on the existing x positioning axes. Alternatively, the systems can be used in a separate test stand for driver assistance systems. This does not add time to the usually tight cycle time in the chassis alignment stands for calibrating driver assistance systems, but significantly optimizing the production process. Unlike other robots, Dürr’s new cobot systems eliminate the need for shut-down devices and safety enclosures, reducing space requirements and costs to help with acceptance in the production environment.

ADAS cobots successfully deployed at Ford Otosan

Ford Otosan is the first user to deploy cobots in its truck plant in Inönü, Turkey. The order included the planning and installation of a new system for chassis and headlight alignment andfront camera, front radar, and side radar calibration systems. Since Ford Otosan only decided on the cobots shortly before placing the order, the schedule for integrating them into the system structure and designing the control setup was very tight. However, the parallel development project couldn’t have gone any smoother thanks to agile working methods. The customer performed the preliminary acceptance on-site in Püttlingen, it was then installed at its intended destination in Turkey and handed over to the customer in August 2023 for the start of production.