Setting of driver assistance systems for commercial vehicles

The x-DASalign truck provides tailored solutions for the flexible and precise setting of modern driver assistance systems for commercial vehicles.

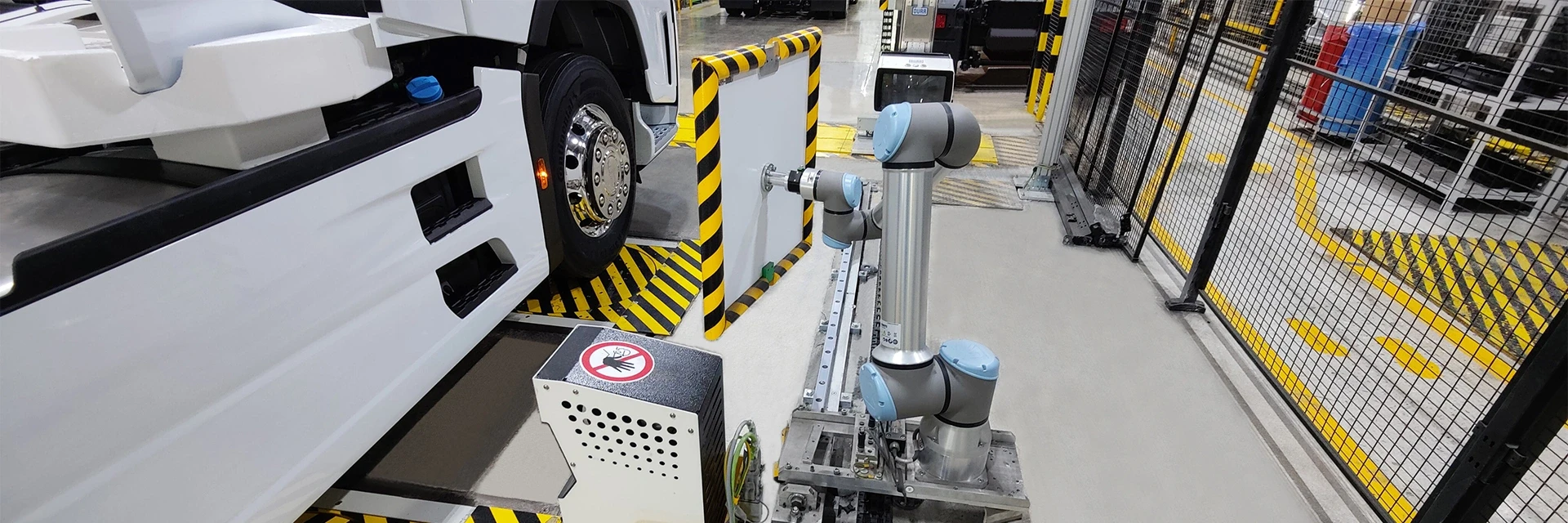

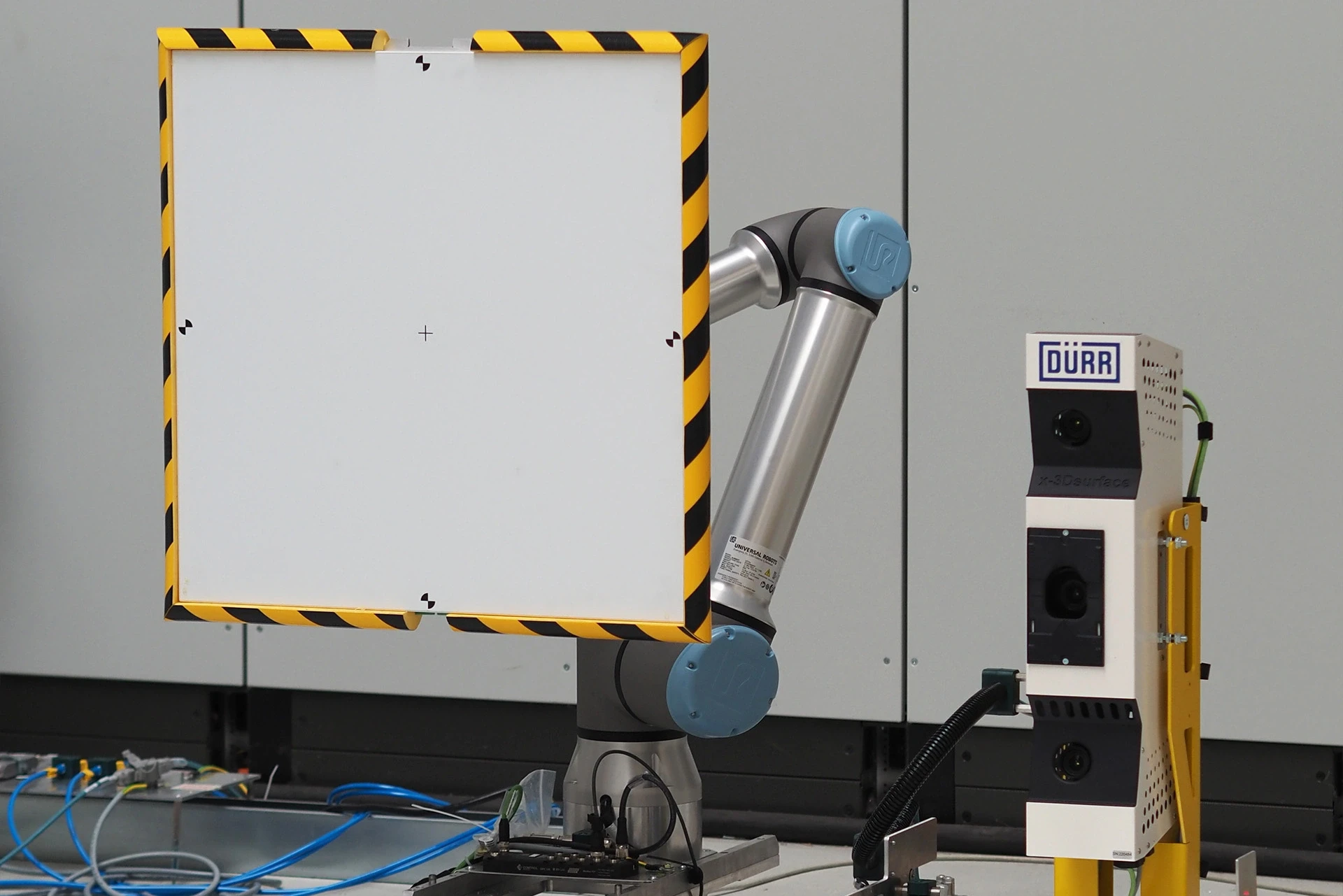

Sensor calibration of driver assistance systems with cobots

Developments in the area of driver assistance systems (Advanced Driver Assistance Systems, ADAS) and autonomous driving are also advancing at pace for commercial vehicles. Moreover, statutory requirements mean that a large number of modern driver assistance systems, such as Lane Departure Warning (LDW), Adaptive Cruise Control (ACC), Advanced Emergency Braking System (AEBS), Active Lane Keep Assist (LKA) or Blind Spot Detection (BSD), are being used to deliver improved levels of road traffic safety.

The sensors operating in the background have to be set precisely and reliably during vehicle production. The high number of vehicle and equipment variants also requires a flexible and modular means for calibrating all of these systems, which can be ensured through the use of collaborating robots, known as cobots.

This is where Dürr offers a range of solutions that meet customers’ differing requirements in terms of space and cycle time.

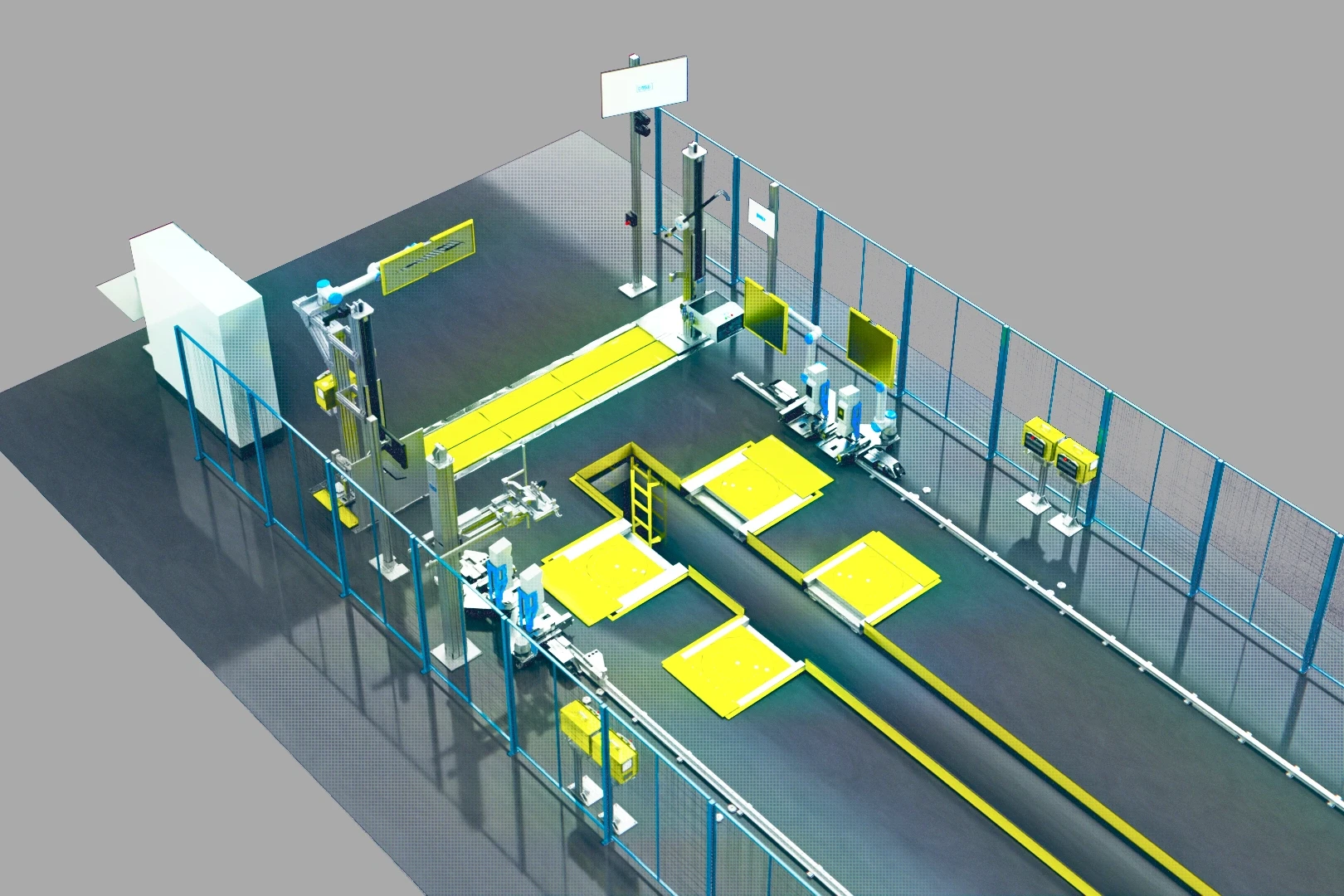

Stand-alone test stand x-DASalign truck optimizes the production process

The latest ADAS test stands make use of cobots for safe, precise, and flexible positioning of the calibration equipment used for camera and radar systems.

Advantages

- End of Line equalization

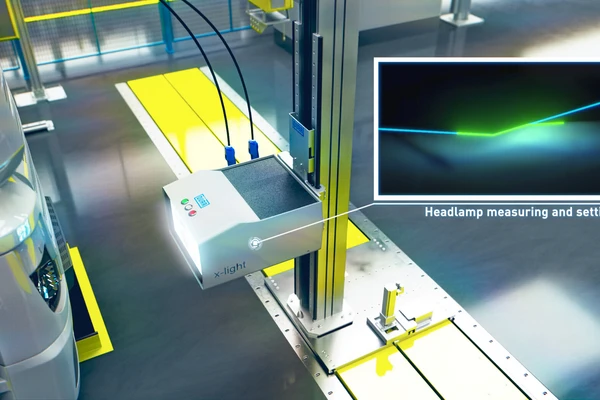

- Reduction in the cycle time by splitting the processes between wheel alignment stand, headlamp setting and driver assistance systems

- Optimization of the production processes

- Same measuring technology (x-3Dsurface) as the wheel alignment stand

- Same set-up master and processes as the wheel alignment stand

Integrated solution in the x-wheel truck d wheel alignment stand

Depending on customer requirements, the ADAS cobots can be integrated into various system types.

Advantages

- Integration into the wheel alignment stands of type x-wheel truck d

- Test stand already prepared for integration

- One test stand for all processes: wheel alignment stand, headlamp setting and setting of driver assistance systems (ADAS – Advanced Driver Assistance Systems)

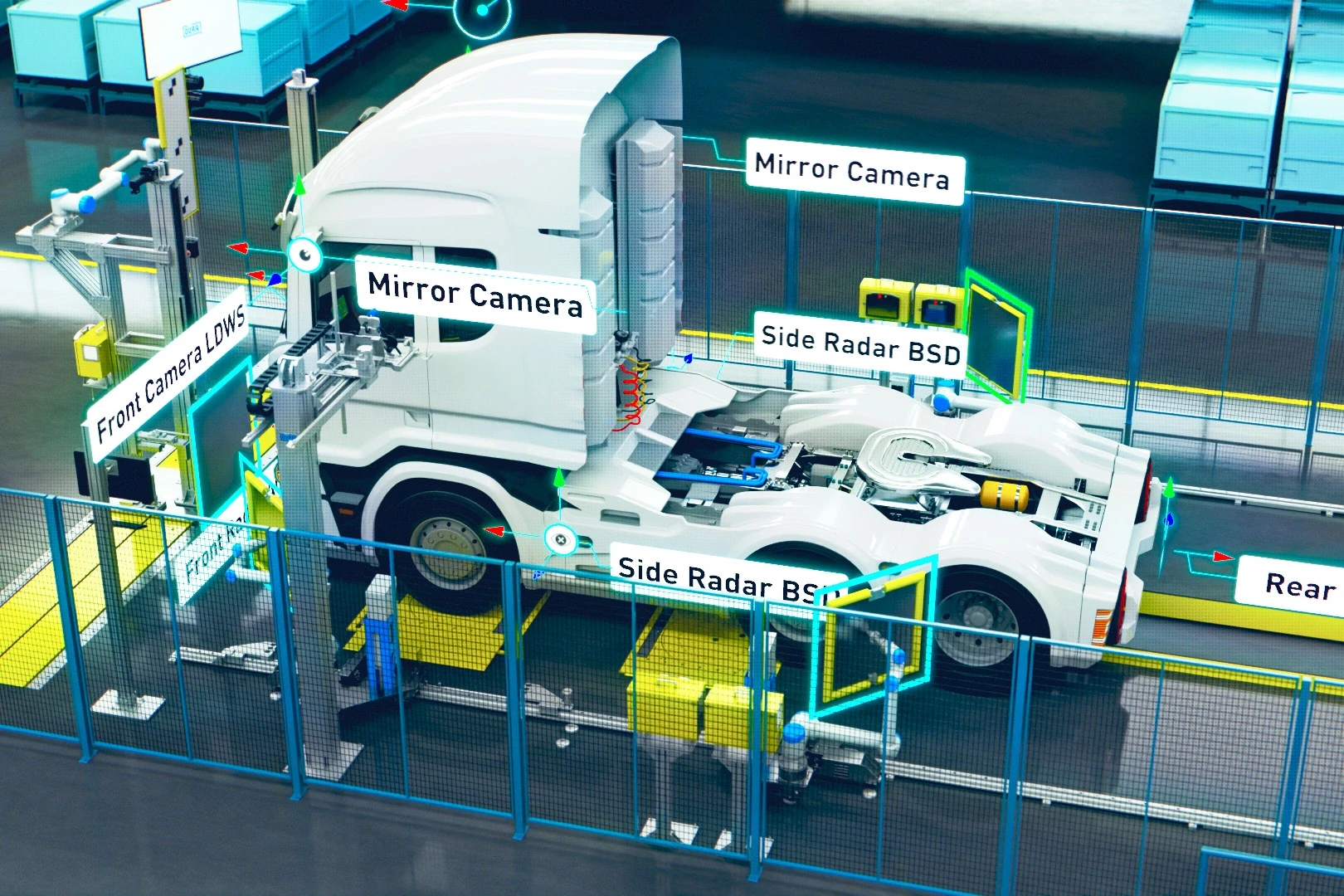

The individual driver assistance systems at a glance:

EU regulations require all trucks manufactured from July 2024 onward to be equipped with a side radar system, for instance in order to detect pedestrians. For calibration purposes, this system needs certain items of calibration equipment (such as a Doppler simulator or aluminum plate), whose positioning must be carried out by, for example, cobots in a highly flexible manner in order to cover the installation positions on the sides of all kinds of commercial vehicles.

Nowadays, the latest generation of commercial vehicles is equipped with cameras instead of side mirrors. This system needs special calibration patterns in order to set the image shown on the driver’s cab monitors in line with requirements.

Modern radar systems are improving all the time, delivering higher resolution and more accurate identification of objects.

This is also increasing calibration requirements in the end-of-line area. Only through highly accurate and reliable wheel alignment for determining the axle track as well as precise positioning of the calibration equipment is it possible to implement all the requirements of the sensor manufacturer.

Front camera systems cover an increasing variety of functions, be it Traffic Sign Recognition (TSR), Lane Departure Warning (LDW) or Active Lane Keep Assist (LKA). The range of object recognition and thus the necessary system precision are growing in step with the further development of the individual systems.

The demands placed on the testing equipment are therefore also increasing, which requires a high degree of precision.

ECU communication

The required communication with the ECUs of the sensors will be executed via the steering wheel balancer x-tronic balancer. The Dürr software x-line is used for automation and visualisation of the adjustment.