One complete battery factory, please.

Nov 14, 2023

Dürr, GROB and Manz have partnered in the field of lithium-ion battery production technology for one year now. Enjoy the first status report.

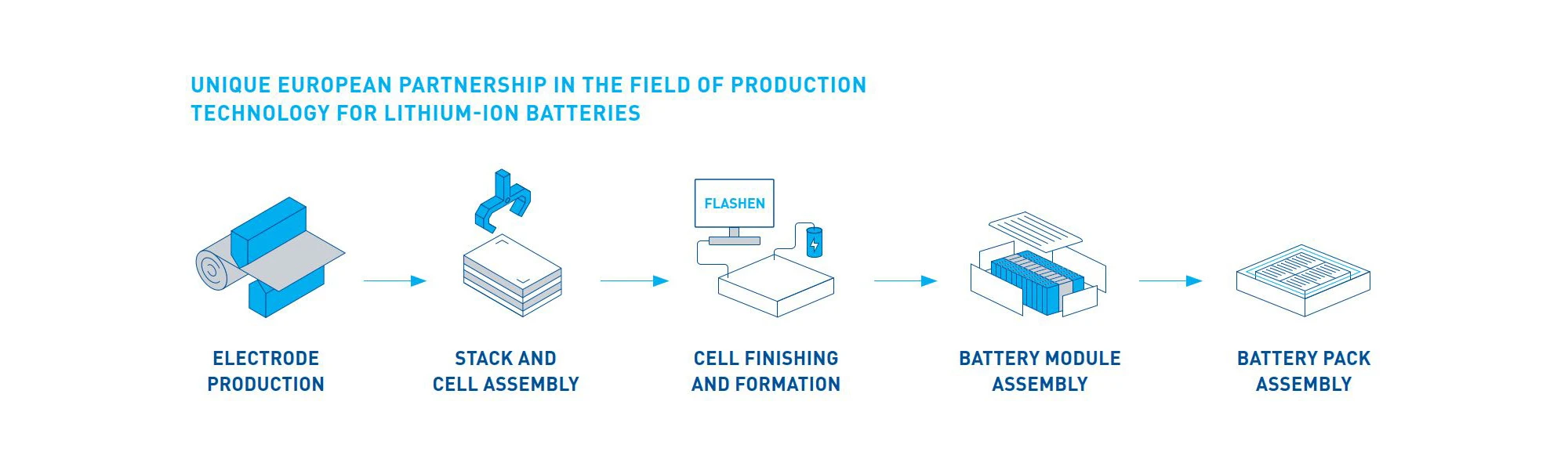

Walk through the streets, and you'll see them everywhere: electric cars, electric motorcycles and even e-buses and e-trucks. Electromobility is obviously booming. Until recently, Europe lacked suppliers offering comprehensive plant technology for manufacturing vehicle batteries from a single source. Thankfully, that changed when Dürr, GROB and Manz formed a unique European partnership focusing on production technology for lithium-ion batteries last year. Their goal was to position themselves in the market as suppliers of complete battery production systems.

The team of three chose the slogan "Made in Europe" to capture the market’s attention. Their combined capabilities present a unique selling point for lithium-ion battery production, providing the complete value chain from a European source. At the same time, they support companies in meeting the rapidly growing demand for high-quality, high-performance batteries. Additionally, the trio aimed to target stationary storage and consumer electronics projects.

Combining skills is the secret to success

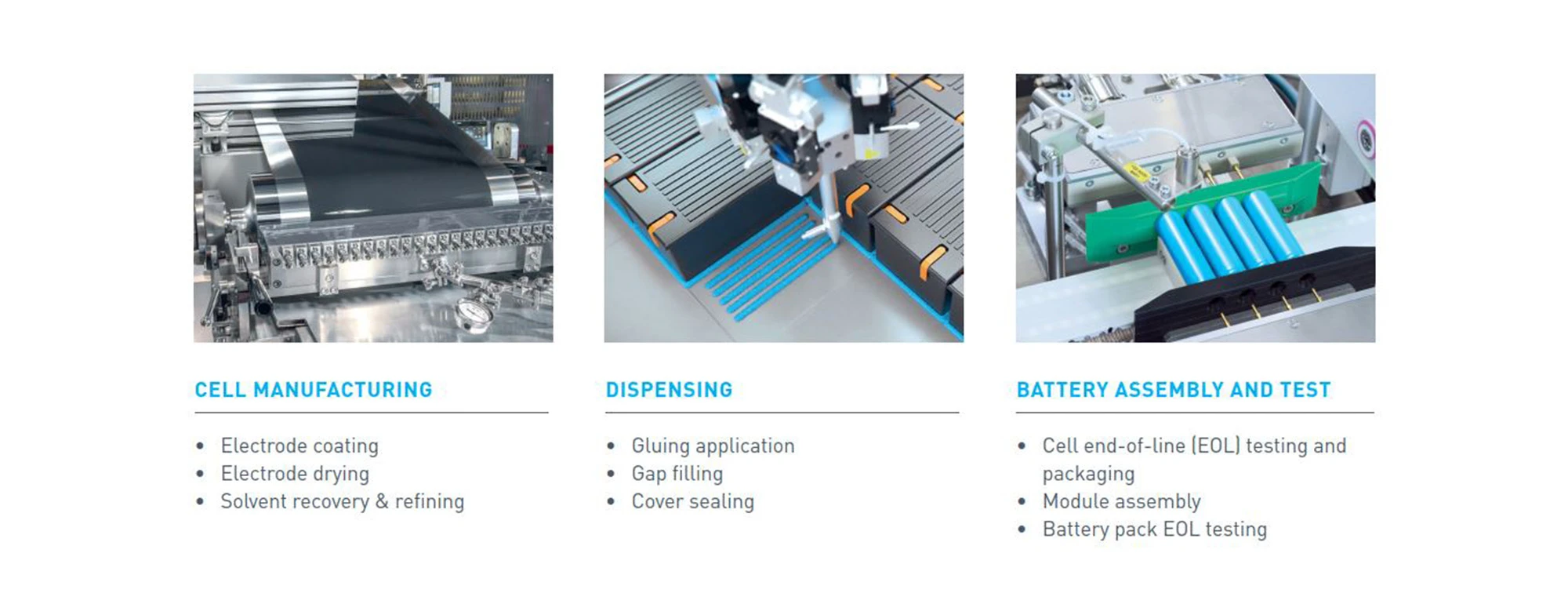

As one of the world's leading mechanical and plant engineering companies, Dürr delivers expertise in electrode manufacturing, the application of glues, sealants and fillers, and assembly and testing technology via its subsidiary teamtechnik Group. Moreover, their expertise in process digitalization is unparalleled. Leveraging this experience, Dürr provides the team with both comprehensive solutions and individual components.

Electrode coating

Dürr supplies innovative technology for simultaneous two-sided and tandem coating. Tandem coating is less sensitive with film quality and optimized for wider films, which is why it's best suited for series and mass production. In addition, highly efficient systems remove, recover, and purify solvents in the exhaust air flow of electrode coating lines, rendering over 95 percent of solvents reusable after distillation, ensuring Dürr’s compliance with global and local emissions standards.

Spotlight on electrode coating

The Cellforce Group already uses Dürr's unique process for simultaneous double-sided electrode coating. In a technology partnership, the Porsche joint venture and Dürr collaborated to commission a high-tech coating plant for high-performance battery cells in Bietigheim-Bissingen in 2022.

Glue, sealant, and filler application

Protecting battery cells from collisions or vibrations is crucial and requires a highly precise application process. Completely sealing battery cells without air inclusions optimizes heat conduction and prevents moisture from penetrating and gases from escaping. Leveraging decades of experience as a global market player, Dürr excels in high-precision adhesive technology, ensuring the application of abrasive materials at a high flow rate while maintaining a stable temperature.

Assembly and test systems

Dürr's subsidiary, teamtechnik, is a leading supplier of modular and flexible assembly and test systems. The company's expertise in end-of-line (EOL) testing and packaging of battery cells, battery module testing and assembly, and EOL battery pack testing is in high demand due to stringent battery production requirements.

Process digitalization

Coordinated interfaces seamlessly integrate machines and systems into Dürr software solutions. Through its subsidiary iTAC, Dürr ensures enhanced productivity, improved agility, and greater sustainability by combining manufacturing and process expertise with manufacturing operations management (MOM), manufacturing analytics, and AI.

As a global high-tech engineering company, Manz AG contributes expertise in developing critical production processes for manufacturing various types of lithium-ion cells and assembling them into battery modules.

For more than 95 years, GROB-WERKE GmbH & Co. KG has been a pioneer in manufacturing and automation systems. The company's strength lies in the design, planning and commissioning of highly complex and customized systems for large-scale production focused on e-mobility within the automotive industry.

One year, one team – the first status report

What started with three signatures and a shared vision in 2022 has developed into a solid partnership a year later. Multiple business units meet weekly, from product development to marketing, to make their collective goal a reality. A design of the envisaged complete solution, including a reference plant, is ready, and the "Battery Production Plant Made in Europe" project has been jointly presented at trade fairs.

German Wankmiller, Chairman of the Board of Management of the GROB Group, Dr. Hannes Schmüser, Member of the Board of Management of the Clean Technology Systems Division at Dürr, and Martin Drasch, Chief Executive Officer of Manz AG, offer more insight into the partnership in this video.

Dr.

Hannes

Schmüser

President & CEO

Clean Technology Systems

Dürr Systems AG

Carl-Benz-Straße 34

74321 Bietigheim-Bissingen

Germany

Carl-Benz-Straße 34

74321 Bietigheim-Bissingen

Germany

German

Wankmiller

Chairman of the Board & CEO

GROB-WERKE GmbH & Co. KG

Industriestraße 4

87719 Mindelheim

Germany

Industriestraße 4

87719 Mindelheim

Germany