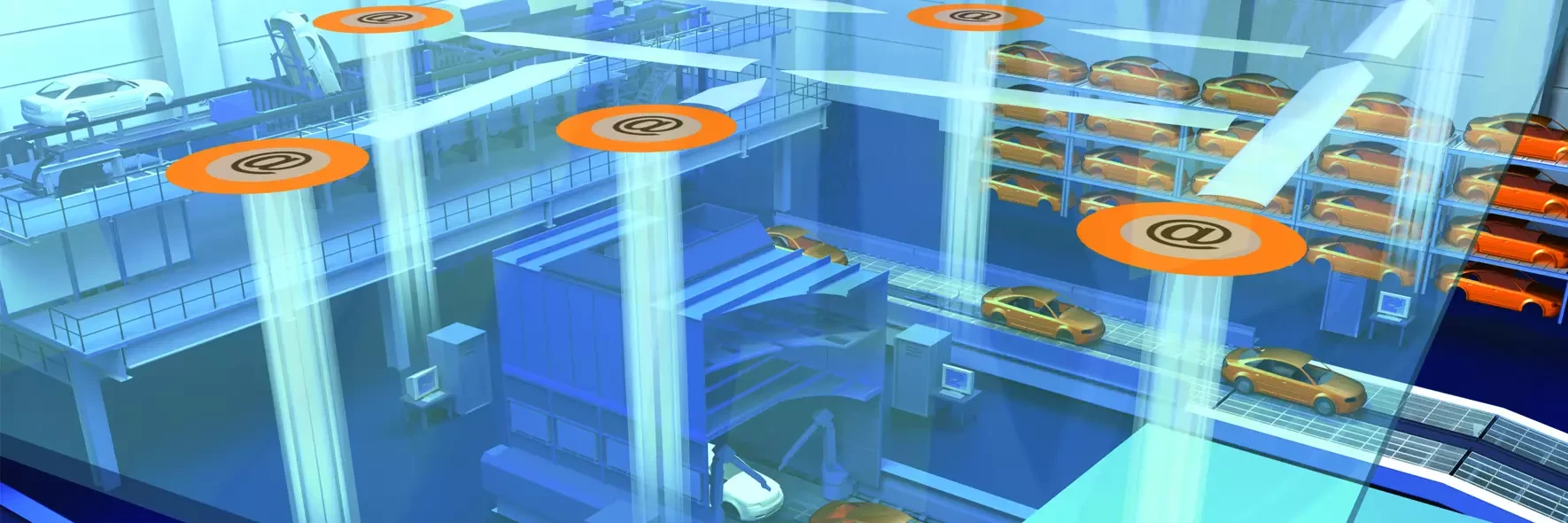

The supervisory control system collates data from the controllers in a plant's individual production sections. The entire manufacturing process can then be efficiently controlled and monitored. Dürr is the only manufacturer of paintshop systems who offers its very own supervisory control system software. In further developing the program, the Group can draw on its proximity to the automotive industry and its knowledge of the production processes used there. Thus Dürr is able to address the special requirements of the automotive industry faster and more precisely.

Among the carmakers who use EcoEMOS in multiple plants are Volkswagen, Hyundai and Ford. Sales of the software have been particularly buoyant recently in the emerging markets. One reason for this is that up-and-coming automotive manufacturers in particular like to purchase the system hardware and control technology from a single source. "This means that our customers receive not only state-of-the-art production systems but also a software tool tailored to it which enables a variety of analyses and evaluations at plant management level," explains Manfred Weil, Head of Dürr's Paint and Final Assembly Systems business unit.

EcoEMOS from Dürr consists of up to 16 modular solutions which share a common platform. The most frequently used modules are "Monitoring" and "Management". "Monitoring" provides at a glance information on the system status, for example the spray booth temperature, the number of car bodies and the material consumption. The "Management" evaluation tool aggregates this information into meaningful production indicators to assess performance and efficiency of the plant. Other frequently ordered modules are "Storage" for managing vehicle body stores and colour and model sequences in production, "Andon", which enables the causes of line stops to be identified, and "Energy Efficiency", which evaluates and lowers energy consumption.

EcoEMOS is now used in over 60 automotive plants in 20 countries. It is offered not just for system orders, i.e. when paintshops and assembly plants are being constructed, but also increasingly as a standalone solution. In a number of plants EcoEMOS already functions as the overall shop-floor IT solution for the bodies-in-white, paintshop, final assembly and storage. "This extensive use is based on the fact that EcoEMOS allows problem-free linkage to a range of PLC systems," says Manfred Weil.

Dürr transacts sales worth double-digit millions of euros with EcoEMOS. In future, control system software is also to be offered increasingly to truck manufacturers, the aviation industry and to producers of engines and gearboxes.