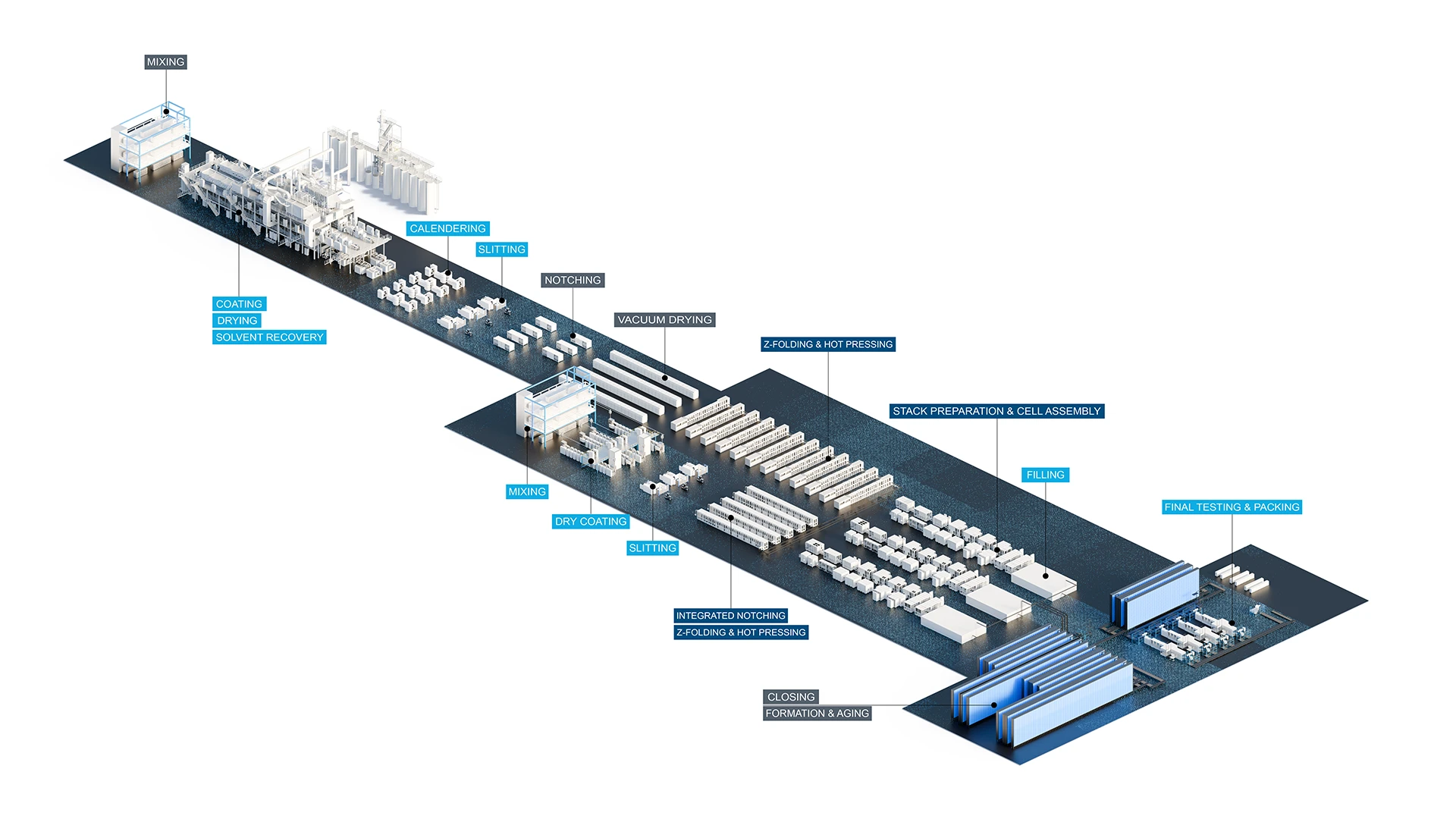

The two global companies Dürr and GROB have been cooperating in the field of production technology for lithium-ion batteries since 2022. The aim is to jointly establish themselves as system suppliers of battery production equipment in Europe and North America. “With our expanded portfolio of highly available machines and systems, we jointly cover almost the entire value chain for battery cell production with our own technologies,” says German Wankmiller, CEO of the GROB Group.

In addition to a classic production layout with wet coating, the partners have developed a concept factory with dry coating and the new Z-folder technology that represents the next generation of battery cell production. Thanks to powerful and innovative technologies, production requires 50 percent less space and 70 percent less energy, resulting in significantly higher space efficiency and lower operating costs.

Efficient and sustainable dry coating

Dürr’s dry coating system X.Cellify DC product family implements the so called “Activated Dry Electrode®“ process from LiCAP Technologies. Dürr has been cooperating with the U.S. coating expert specifically in the field of dry coating since 2023. The Dürr machine uses a dry-mixed active material instead of conventional slurry. This powder mixture is pressed into a free-standing film using calender machines, which is then laminated onto both sides of the collector foil. Compared to wet coating, this eliminates the drying process as well as the recovery and treatment of solvents – saving space, energy, and costs. The free-standing film also offers advantages in terms of material efficiency, as excess film material can be completely returned to the production process before lamination onto the collector foil.

The recently achieved successful proof of concept demonstrates that the Dürr machine is capable of performing the dry coating process with consistently high quality. It can be scaled up, and Dürr is actively seeking pilot partners in the industry.

High-speed cell assembly

With the new generation of Z-folders, which integrate the notching process, GROB achieves higher performance with less space. For particularly stable and reliable system technology, the separator is guided over a few deflection rollers with very even and low web tension. Thanks to a high-quality magazine buffer system for the electrodes, the system achieves 95 percent availability.

Precise electrolyte filling with high pressure

A process developed by Dürr enables battery cells to be filled in a single step without residual gas. Unlike the conventional process, the electrolyte is filled directly into the cells at up to 30 bar. The filling pressure is thus two to three times higher than the current industry standard. The process design enables precise dosing and shortens both the filling process and the subsequent penetration of the electrolyte into the active material.

End-to-end digitalization

The equipment technology from Dürr and GROB is complemented by end-to-end digital mapping of the production process. Even in the planning phase before production starts, a digital twin enables simulation of the entire factory and speeds up implementation on site. The data from the simulation flows into the MES/MOM software of Dürr’s subsidiary iTAC, which can be used to control and plan all production steps in battery manufacturing. Important functions here are traceability and quality analysis to avoid errors in production. This results in high overall equipment effectiveness.

Innovations in wet coating

Dürr has also further optimized its technologies in terms of performance and energy efficiency in the classic wet coating process. One example is the automation of the coating station and the slot dies, which form a closed control loop for the layer thickness – resulting in faster production start-up and reduced scrap rate. “Adding automated slot die profile control provides our customers with the ability to not only reduce the machine startup time, but it also ensures quality throughout the production process by maintaining the coating uniformity.” explains Adam Shambeau, Senior Director of Dürr Lithium-Ion Batteries Americas, “Scrap reduction and machine up-time are critical to our customer’s success, so enhancing our products through automation or innovating our offerings with dual-side coating technology to reduce the total cost of ownership are two great examples where our products bring value to our customers.”

In the subsequent drying process, battery manufacturers can use laser dryers to achieve a 50 percent faster web speed and particularly energy-efficient drying. After drying, the electrode coating is densified using calendering machines. The machines from Dürr work with particular precision using “Dynamic Gap Control”: two sensors measure the distance between the two rollers with an accuracy of 0.5 µm. This results in a very uniform layer thickness, with no more force being applied than necessary. Dürr's calenders are used for both wet coating and dry coating to compress the film.

At the Battery Show North America 2025 from October 6 to 9, Dürr and GROB will be presenting their concept factory as a physical 3D model at their joint booth 3822 at Detroit’s Huntington Place Convention Center.

Dürr will be introducing a new naming concept. The company is bringing together its products for electrode coating and electrolyte filling under the new name “X.Cellify.”